Uniform substance based laser induced breakdown spectroscopy correction method

A laser-induced breakdown and uniform technology, used in thermal excitation analysis, material excitation analysis, material analysis by optical means, etc., can solve the problems of high labor cost, low dust removal efficiency, easy damage to the atomized mirror, etc. Maintenance cycle, the effect of reducing the number of times of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In this embodiment, cement is used as the sample to be tested to specifically introduce a laser-induced breakdown spectrum correction method based on a uniform substance of the present invention, which includes the following steps:

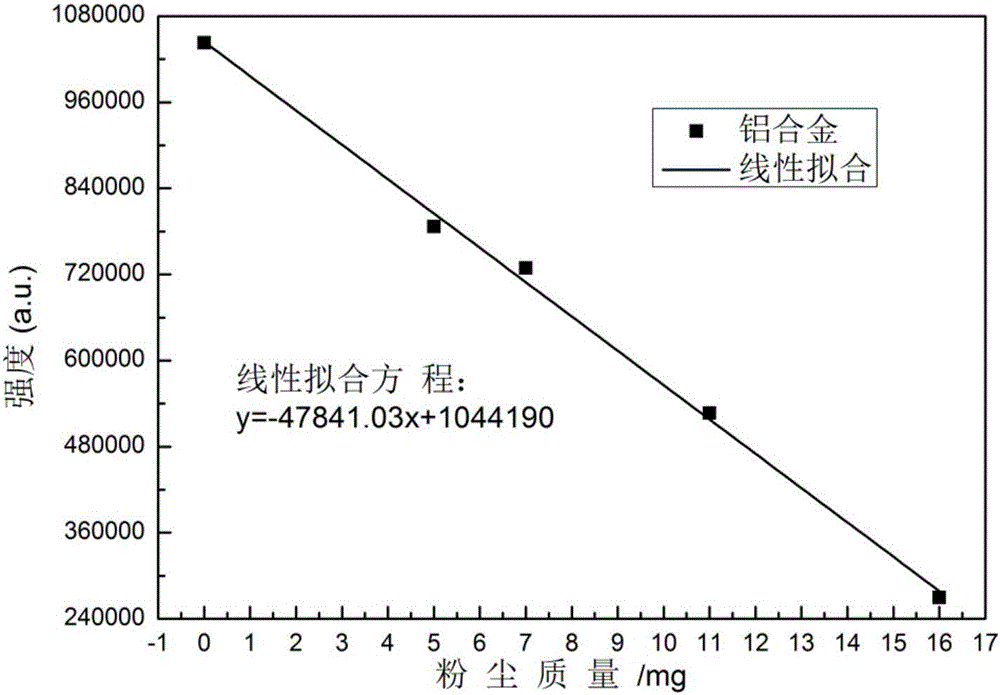

[0019] (a) Select a uniform substance with hard texture, ablation resistance on the surface, uniform distribution, consistent inside and outside; because 6061 aluminum alloy is hard, ablation resistant, uniformly distributed, consistent inside and outside, and RSD between groups is small, choose it as a uniform substance Meet the relevant selection requirements. figure 1 Shows the calculated value of the RSD between the 45 spectral lines in the plasma spectrum of the aluminum alloy 1800 group, and the variation range is 0.4 to 1.8%;

[0020] (b) After weighing five clean lenses of the same kind, use a blower to raise the dust and evenly scatter them on the surface of the lenses to allow them to receive different degrees of pollution. After weighi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com