Multifunctional SSF/B type polyester finishing agent and preparation method thereof

A multifunctional, finishing agent technology, applied in the direction of anti-staining/anti-fouling fibers, improved hand fibers, etc., can solve the problems of not meeting other functions, single performance, containing chemical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

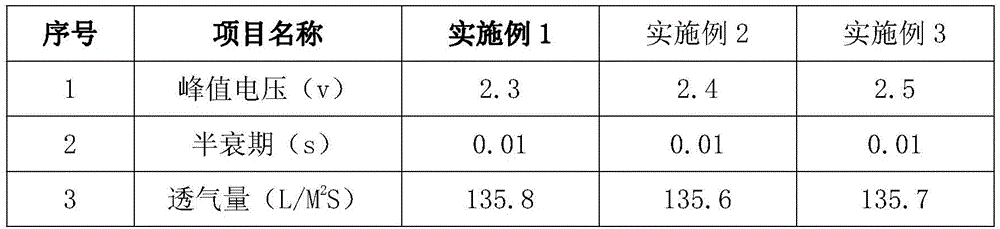

Examples

Embodiment 1

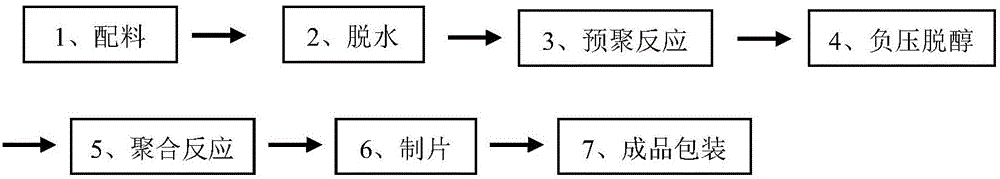

[0030] A preparation method of SSF / B type polyester multifunctional finishing agent, which is characterized in that it comprises the following steps:

[0031] 1. Add 450kg polyethylene glycol and 100kg triethylene glycol into a 1500L stainless steel reactor with stirring and mechanical seal, start stirring, slowly heat up to 98°C, turn on vacuum, and control the vacuum degree at -0.086MPa Dehydrate for 1 hour, then cool down to 60°C;

[0032] 2. Then add 240kg of methyl phthalate, 70kg of toluene, and 6kg of calcium acetate catalyst respectively, start stirring, heat up, the temperature rises to 105°C, and prepolymerizes for 3 hours; continue to heat up to 135°C, and the vacuum degree is controlled at - Distill for 4 hours under the condition of 0.095MPa, so that part of the remaining triethylene glycol can be fully removed, and the recovered alcohol can be reused;

[0033] 3. After the distillation is completed, continue to heat up to 230°C, turn on the vacuum, and control t...

Embodiment 2

[0036] A preparation method of SSF / B type polyester multifunctional finishing agent, which is characterized in that it comprises the following steps:

[0037] 1. Add 650kg polyethylene glycol and 150kg triethylene glycol into a 1500L stainless steel reactor with stirring and mechanical seal, start stirring, slowly heat up to 96°C, turn on vacuum, and control the vacuum degree at -0.088MPa Dehydrate for 1 hour, then cool down to 60°C;

[0038] 2. Then add 350kg of methyl phthalate, 100kg of toluene, and 8kg of calcium lactate catalyst respectively, start stirring, heat up, the temperature rises to 110°C, and prepolymerizes for 3.5 hours; continue to heat up to 140°C, and the vacuum degree is controlled at - Distill for 3.5 hours under the condition of 0.096MPa, so that part of the remaining triethylene glycol can be fully removed, and the recovered alcohol can be reused;

[0039] 3. After the distillation is completed, continue to heat up to 240°C, turn on the vacuum, and cont...

Embodiment 3

[0042] A preparation method of SSF / B type polyester multifunctional finishing agent, which is characterized in that it comprises the following steps:

[0043] 1. Add 500kg polyethylene glycol and 120kg triethylene glycol into a 1500L stainless steel reactor with stirring and mechanical seal, start stirring, slowly heat up to 101°C, turn on vacuum, and control the vacuum degree at -0.087MPa Dehydrate for 1 hour, then cool down to 60°C;

[0044] 2. Then add 300kg of methyl phthalate, 80kg of toluene, and 9kg of calcium gluconate catalyst respectively, start stirring, heat up, the temperature rises to 112°C, and prepolymerizes for 4 hours; continue to heat up to 130°C, and the vacuum degree is controlled at - Distill for 3 hours under the condition of 0.095MPa, so that part of the remaining triethylene glycol can be fully removed, and the recovered alcohol can be reused;

[0045] 3. After the distillation is completed, continue to heat up to 235°C, turn on the vacuum, and contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com