A Method for Eliminating Residual Stress of High Strength Rare Earth Magnesium Alloy Thin-Wall Castings

A thin-wall casting and residual stress technology, applied to high-strength rare-earth magnesium alloys, refers to Mg-Y-Nd series high-strength magnesium alloys, which integrates eliminating residual stress of high-strength rare-earth magnesium alloy thin-wall castings and improving mechanical properties, eliminating high-strength rare-earth magnesium alloys. In the field of residual stress of thin-walled castings, it can solve the problems of high cost, workpiece deformation and high cost, and achieve the effect of homogenizing residual stress, improving mechanical properties and eliminating residual stress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

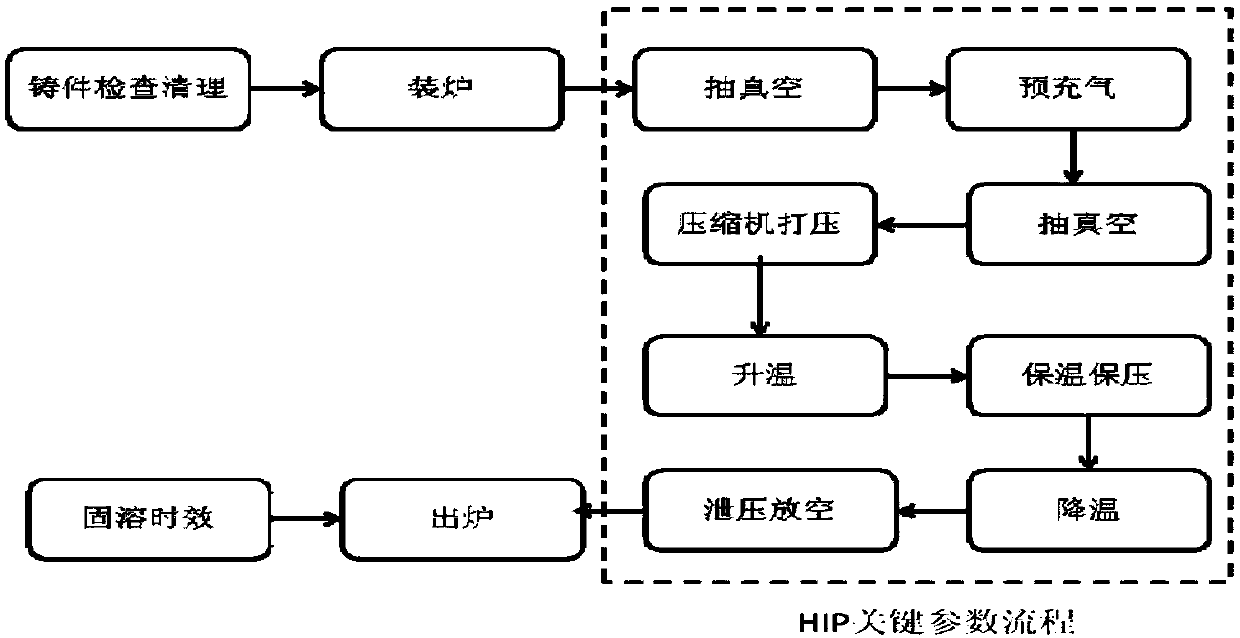

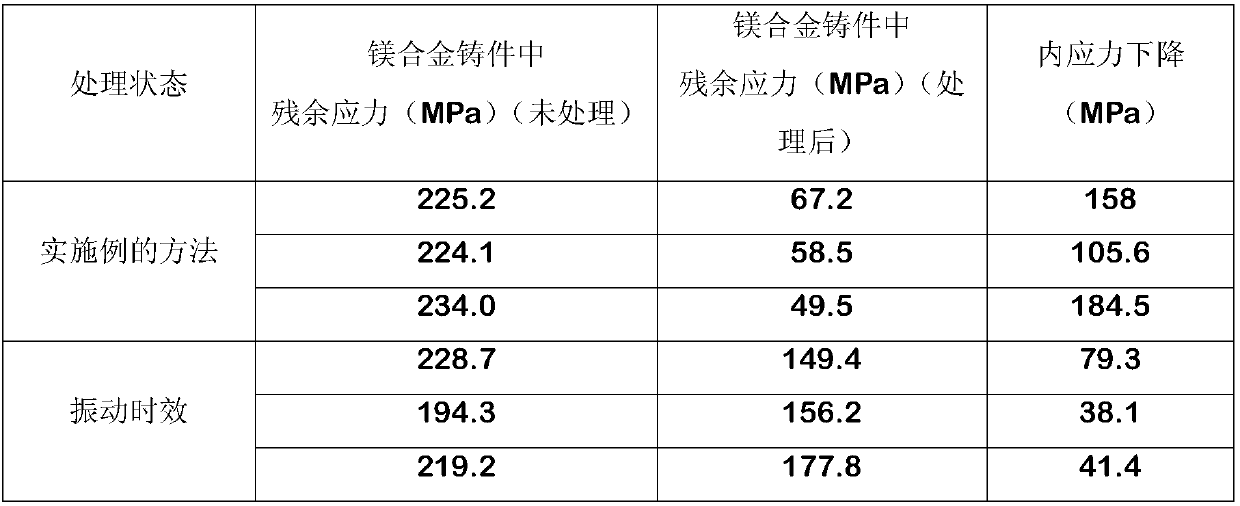

[0036] A method for eliminating residual stress of WNG421 (Mg-4Y-2Nd-1Gd) thin-walled casting, the steps of the method comprising:

[0037](1) Scrub the surface of the WNG421 (Mg-4Y-2Nd-1Gd) thin-walled casting blank with acetone to remove surface oil stains, and ensure that no stains or oil stains are allowed on the surface. After cleaning, put it into the center of the hot isostatic pressing furnace body , and close the furnace door;

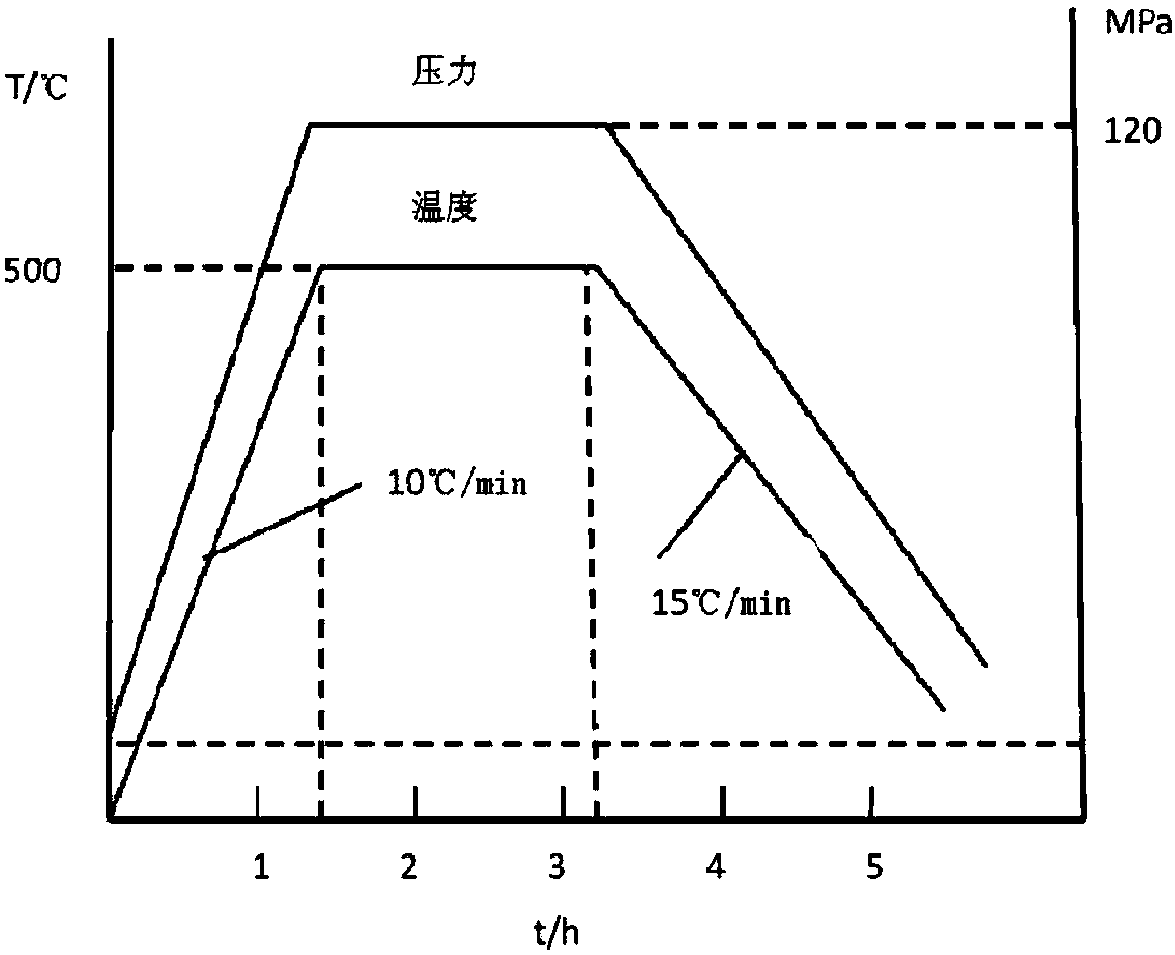

[0038] (2) vacuumize the hot isostatic pressing furnace body for the first time, when the vacuum degree in the hot isostatic pressing furnace body is 6 milliPascals, fill the air in the argon displacement hot isostatic pressing furnace body, afterwards Fill in argon all the time, and then carry out the second vacuuming until the vacuum degree of the hot isostatic pressing furnace body reaches 10 mPa, then heat the hot isostatic pressing furnace body. The heating process parameters are: the temperature is 500°C, The heating rate is 10°C / min; o...

Embodiment 2

[0050] A method for eliminating residual stress of WNG421 (Mg-4Y-2Nd-1Gd) thin-walled casting, the steps of the method comprising:

[0051] (1) Scrub the surface of the WNG421 (Mg-4Y-2Nd-1Gd) thin-walled casting blank with acetone to remove surface oil stains, and ensure that no stains or oil stains are allowed on the surface. After cleaning, put it into the center of the hot isostatic pressing furnace body , and close the furnace door;

[0052] (2) vacuumize the hot isostatic pressing furnace body for the first time, when the vacuum degree in the hot isostatic pressing furnace body is 4 milliPascals, fill the air in the argon displacement hot isostatic pressing furnace body, afterwards Fill in argon all the time, and then carry out the second vacuuming until the vacuum degree of the hot isostatic pressing furnace body reaches 8 mPa, then heat the hot isostatic pressing furnace body. The heating process parameters are: the temperature is 520°C, The heating rate is 12°C / min; o...

Embodiment 3

[0057] A method for eliminating residual stress of WNG421 (Mg-4Y-2Nd-1Gd) thin-walled casting, the steps of the method comprising:

[0058] (1) Scrub the surface of the WNG421 (Mg-4Y-2Nd-1Gd) thin-walled casting blank with acetone to remove surface oil stains, and ensure that no stains or oil stains are allowed on the surface. After cleaning, put it into the center of the hot isostatic pressing furnace body , and close the furnace door;

[0059] (2) vacuumize the hot isostatic pressing furnace body for the first time, when the vacuum degree in the hot isostatic pressing furnace body is 5 milliPascals, fill in the air in the argon displacement hot isostatic pressing furnace body, afterwards Fill in argon all the time, and then carry out the second vacuuming until the vacuum degree of the hot isostatic pressing furnace body reaches 9 mPa, then heat the hot isostatic pressing furnace body. The heating process parameters are: the temperature is 510°C, The heating rate is 11°C / min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com