Modified PVB resin powder and preparation method thereof

A resin powder and modification technology, applied in the direction of film/sheet adhesive, adhesive additive, non-polymer adhesive additive, etc., can solve the problem of reducing hydroxyl content, limited noise reduction, plasticizer precipitation, etc. problems, to avoid powder pollution, solve uneven dispersion, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, but not to limit the present invention.

[0035] The specific preparation method is as follows

[0036] (1) Condensation reaction:

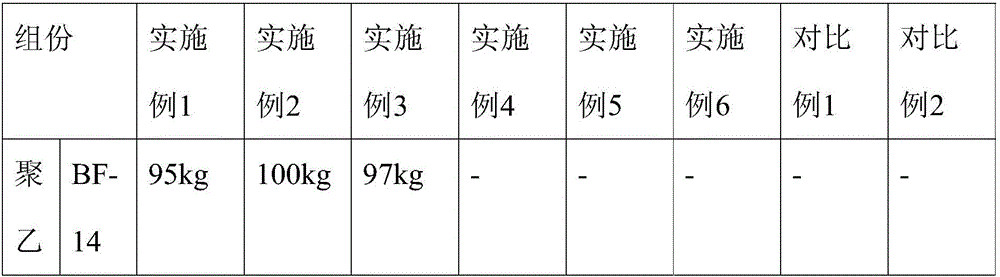

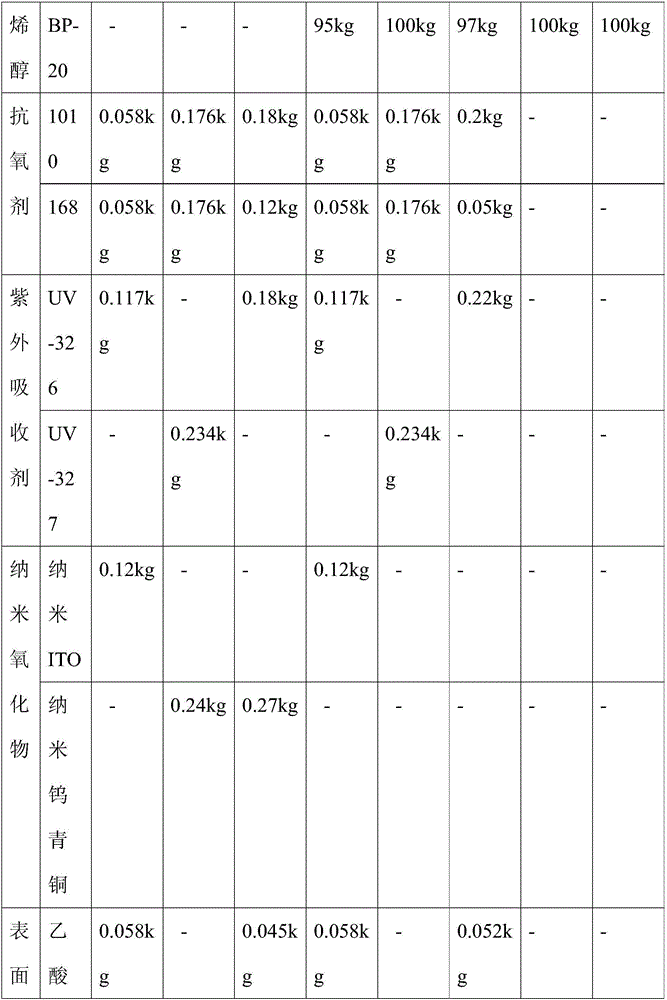

[0037] First, use 95°C water and an appropriate amount of polyvinyl alcohol in the reactor to form a solution with a concentration of less than 10%, and then cool the solution to 45°C and add an appropriate amount of additives (antioxidants, ultraviolet absorbers, nano oxides, etc.) , surface tension modifier) and n-butyraldehyde were stirred for 1 h; secondly, the reaction mixture was cooled to 20° C., an appropriate amount of catalyst hydrochloric acid was added, and the reaction was kept for at least 1 hour, and then th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Financial index | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com