Three-station automatic grinding device for liner of electric cooker

A rice cooker and three-station technology, which is applied in the direction of grinding automatic control device, grinding drive device, grinding/polishing safety device, etc., can solve the problems of noise and dust pollution, low work efficiency, low environmental protection performance, etc. Eliminate noise and dust pollution, improve processing quality and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

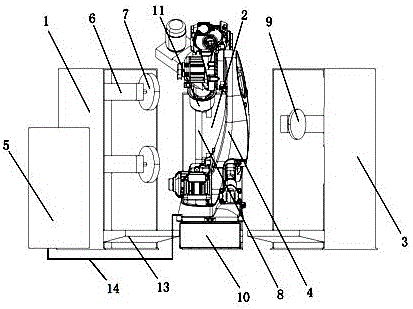

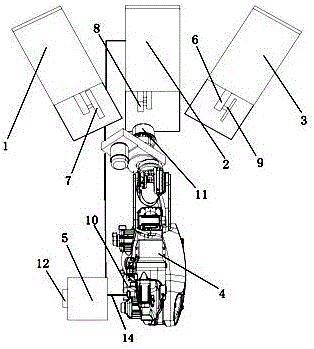

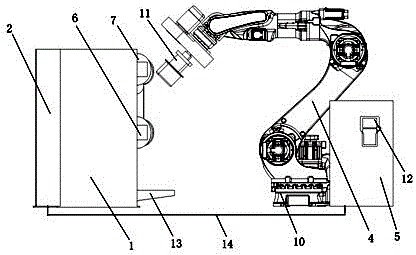

[0021] The present invention will be described in more detail below in conjunction with the accompanying drawings.

[0022] as attached Figure 1-6 As shown, a three-station electric rice cooker inner tank automatic polishing device includes a polishing station 1, a wire drawing station 2, a polishing station 3, a robot 4, an electric control cabinet 5 and a wire drawing belt 6, and is characterized in that: The grinding station 1 is provided with a fixed plate 6 and a waste table 13, and the fixed plate 6 of the grinding station 2 is provided with a grinding wheel 7 through a connecting shaft 17, and the described grinding station 1 is provided with a motor 15, Motor 15 is provided with driving wheel 16, and driving wheel 16 is connected with grinding wheel 7 by belt 20, and described motor 15 and grinding wheel 7 are arranged as a one-to-one corresponding structure, and motor 15 is connected with connecting wire 14 and The electric control cabinet 5 is connected, and the wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com