A kind of mulberry leaf granular tea and preparation method thereof

A technology of granular tea and mulberry leaves, which is applied in the fields of mulberry leaf processing and agricultural product processing, can solve the problems of wasting biological resources, lack of aroma, and weak flavor, etc., and achieve the effects of increasing resource utilization, reducing production costs, and solving poor appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

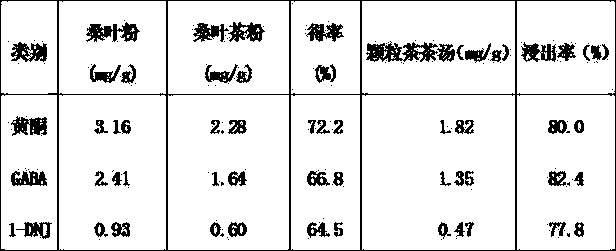

Image

Examples

Embodiment 1

[0045] (1) Pick 90kg of fresh mulberry leaves, and remove residual leaves such as diseases and insect pests;

[0046] (2) Boil fresh mulberry leaves in water at 85°C for 30 seconds, then remove and drain, and let it air dry naturally;

[0047] (3) Dry the mulberry leaves after finishing and drying at 85°C;

[0048] (4) Pulverize the dried mulberry leaves and sieve them through a 100-mesh sieve to obtain mulberry leaf tea powder for later use;

[0049] (5) Mix 40kg of mulberry leaf tea powder, 40kg of high-gluten wheat flour, and 2kg of guar gum evenly, add 20kg of water, and make a dough;

[0050] (6) Let the prepared dough rest at 35°C for 30 minutes;

[0051] (7) Use a molding machine to shape the rested dough into granules, with an average particle size of 1.5 mm;

[0052] (8) Put the formed granules in quick freezing at -10°C for 40 minutes as soon as possible;

[0053] (9) Bake the quick-frozen granules at 115°C for 40 minutes, and then naturally cool to room temperatur...

Embodiment 2

[0056] (1) Pick 150kg of fresh mulberry leaves, and remove residual leaves such as diseases and insect pests;

[0057] (2) Boil fresh mulberry leaves in water at 100°C for 10 seconds, then remove and drain, and let it air dry naturally;

[0058] (3) Dry the mulberry leaves after finishing and drying at 110°C;

[0059] (4) Pulverize the dried mulberry leaves and sieve them through a 200-mesh sieve to obtain mulberry leaf tea powder for later use;

[0060] (5) Mix 60kg of mulberry leaf tea powder, 60kg of high-gluten wheat flour, and 2kg of xanthan gum evenly, add 40kg of water, and make a dough;

[0061] (6) Let the prepared dough rest at 40°C for 15 minutes;

[0062] (7) Use a molding machine to shape the rested dough into granules, with an average particle size of 3.0mm;

[0063] (8) Put the formed granules in quick freezing at -20°C for 20 minutes as soon as possible;

[0064] (9) Bake the quick-frozen granules at 115°C for 20 minutes, and then naturally cool to room tem...

Embodiment 3

[0067] (1) Pick 100kg of fresh mulberry leaves, and remove residual leaves such as diseases and insect pests;

[0068] (2) Boil fresh mulberry leaves in water at 90°C for 20 seconds, then remove and drain, and let it air dry naturally;

[0069] (3) Dry the mulberry leaves after finishing and drying at 90°C;

[0070] (4) Crush the dried mulberry leaves, sieve them through a 100-mesh sieve, and set aside;

[0071] (5) Mix 49kg of mulberry leaf tea powder, 49kg of high-gluten wheat flour, 1kg of xanthan gum, and 1kg of guar gum, add 25kg of water, and make a dough;

[0072] (6) Let the prepared dough stand at 40°C for 20 minutes;

[0073] (7) Use a molding machine to shape the rested dough into granules, with an average particle size of 2.5mm;

[0074] (8) Put the formed granules in quick freezing at -20°C for 30 minutes as soon as possible;

[0075] (9) Bake the quick-frozen granules at 130°C for 30 minutes, and then naturally cool to room temperature to obtain the mulberry ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com