Mobile phone antenna and electroless plating technology thereof

A mobile phone antenna and antenna technology, applied in the field of radio communication, can solve the problems of high defect rate, low output and production efficiency, and high production cost, and achieve the effects of reducing production cost, improving production efficiency, and shortening development cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

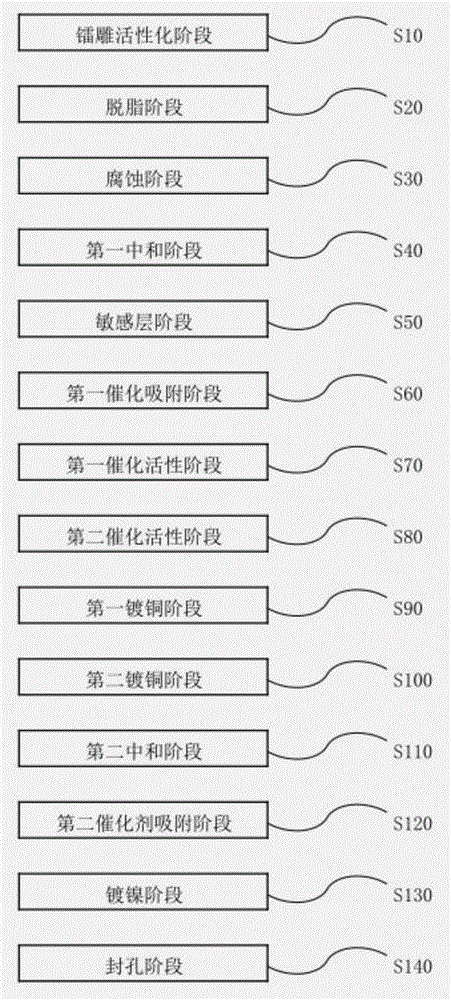

[0031] A chemical plating process for a mobile phone antenna includes the following steps:

[0032] S10: Radium engraves the surface of the antenna part of the material to be processed with a uniform uneven surface;

[0033] S20: Treat the surface to be plated with an alkaline degreasing agent of 150g / L concentration for 1 min to remove oil stains and dust on the surface;

[0034] S30: Soak the plated surface with 150ml / L sulfuric acid at 55-65℃ for 2min;

[0035] S40: Soak the plated surface with 100ml / L hydrochloric acid for 1min;

[0036] S50: Soak the plated surface with 5-10g / L tin chloride solution for 2 minutes to make the uneven surface of the plated part absorb the metal ions in the tin chloride solution;

[0037] S60: Soak the plated surface with 100-200ml / L palladium chloride solution for 2 minutes;

[0038] S70: Soak the plated surface with 50-100g / L organic acid solution for 1 minute to remove the tin ions adsorbed by the plated surface from the tin chloride solution;

[0039]...

Embodiment 2

[0048] A chemical plating process for a mobile phone antenna includes the following steps:

[0049] S10: Radium engraves the surface of the antenna part of the material to be processed with a uniform uneven surface;

[0050] S20: Treat the surface to be plated with an alkaline degreasing agent of 150g / L concentration for 1 min to remove oil stains and dust on the surface;

[0051] S30: Soak the plated surface with 150ml / L sulfuric acid at 55-65℃ for 6min;

[0052] S40: Soak the plated surface with 100ml / L hydrochloric acid for 1.5min;

[0053] S50: Soak the plated surface with 5-10g / L tin chloride solution for 2.5 minutes to make the uneven surface of the plated part adsorb the metal ions in the tin chloride solution;

[0054] S60: Soak the plated surface for 3.5min with 100-200ml / L palladium chloride solution;

[0055] S70: Soak the plated surface with 50-100g / L organic acid solution for 2 minutes to remove the tin ions adsorbed by the plated surface from the tin chloride solution;

[005...

Embodiment 3

[0065] A chemical plating process for a mobile phone antenna includes the following steps:

[0066] S10: Radium engraves the surface of the antenna part of the material to be processed with a uniform uneven surface;

[0067] S20: Treat the surface to be plated with an alkaline degreasing agent of 150g / L concentration for 1 min to remove oil stains and dust on the surface;

[0068] S30: Soak the plated surface with 150ml / L sulfuric acid at 55-65℃ for 10min;

[0069] S40: Soak the plated surface with 100ml / L hydrochloric acid for 2 minutes;

[0070] S50: Soak the plated surface with 5-10g / L tin chloride solution for 3 minutes to make the uneven surface of the plated part absorb the metal ions in the tin chloride solution;

[0071] S60: Soak the plated surface with 100-200ml / L palladium chloride solution for 5 minutes;

[0072] S70: Soak the plated surface with 50-100g / L organic acid solution for 3 minutes to remove the tin ions adsorbed by the plated surface from the tin chloride solution; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com