UV led packaging method

A LED packaging and LED chip technology, applied in semiconductor devices, electrical components, circuits, etc., can solve problems affecting chip performance, loss of sealing performance, and easy aging of materials, so as to achieve uniform protective film, prolong sealing time, and improve cleanliness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

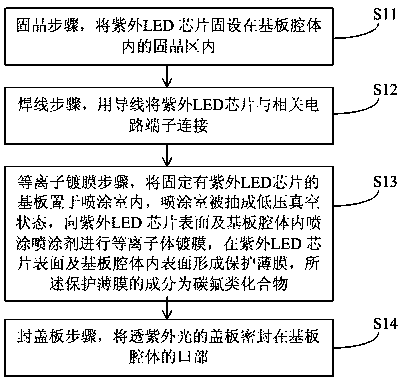

[0034] This embodiment proposes a method for packaging ultraviolet LEDs, such as figure 1 shown, including the following steps:

[0035] S11, the crystal-bonding step, fixing the ultraviolet LED chip in the crystal-bonding area in the cavity of the substrate;

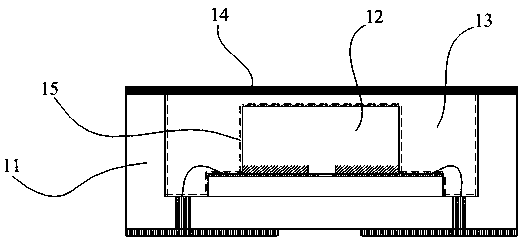

[0036] This embodiment adopts chip-on-board packaging technology, such as figure 2 As shown, a substrate 11 is included, and a cavity 13 for accommodating a chip 12 is provided on the substrate 11 .

[0037] S12, wire bonding step, connect the ultraviolet LED chip to the relevant circuit terminal with a wire;

[0038] S13, plasma coating step, place the substrate with the UV LED chip fixed in the spraying chamber, the spraying chamber is pumped into a low-pressure vacuum state, spray the spraying agent on the surface of the UV LED chip and the cavity of the substrate for plasma coating, and place the substrate on the surface of the UV LED chip And a protective film is formed on the inner surface of the substrate cav...

Embodiment 2

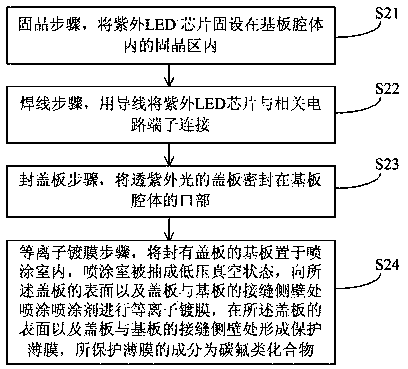

[0049] This embodiment proposes another UV LED packaging method, such as image 3 shown, including the following steps:

[0050] S21, the crystal-bonding step, fixing the ultraviolet LED chip in the crystal-bonding area in the cavity of the substrate;

[0051] This embodiment adopts chip-on-board packaging technology, such as Figure 4 As shown, a substrate 11 is included, and a cavity 13 for accommodating a chip 12 is provided on the substrate 11 .

[0052] S22, wire bonding step, connect the ultraviolet LED chip to the relevant circuit terminal with a wire;

[0053] S23 , the step of sealing the cover plate, sealing the cover plate transparent to the ultraviolet light on the mouth of the substrate cavity.

[0054] S24, plasma coating step, place the substrate sealed with the cover plate in the spraying chamber, the spraying chamber is pumped into a low-pressure vacuum state, and spray the spraying agent on the surface of the cover plate and the joint side wall of the cove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com