Erosion test device and method with capacity of controlling temperature, angle, flow velocity and time

A test device and angle technology, applied in the direction of measurement device, strength characteristics, test wear resistance, etc., can solve the problems of low degree of automation, waste of resources, small footprint, etc., to simplify the operation process, reduce labor costs, and automate high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

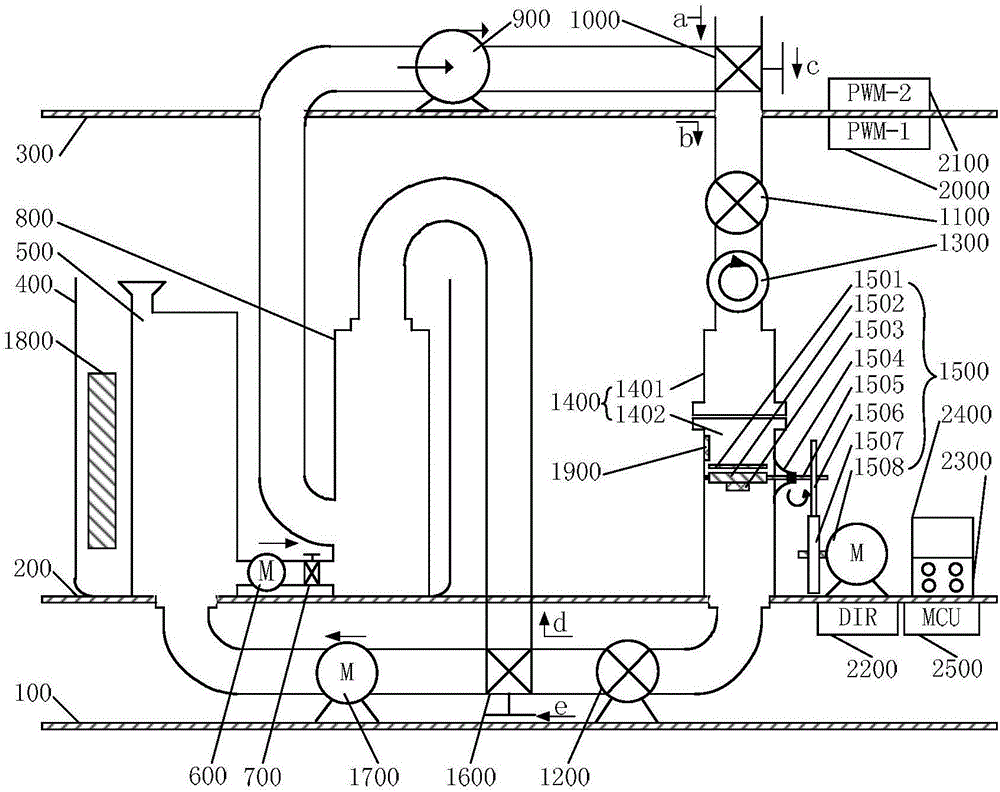

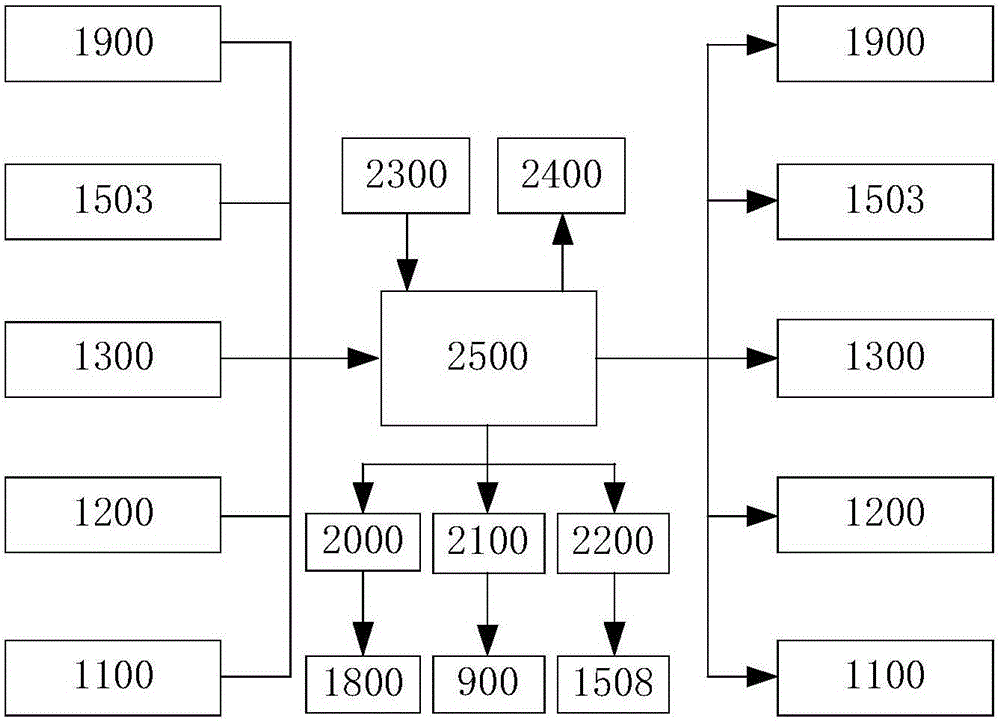

[0034] combine Figure 1 to Figure 4 , the technical solution of the present invention is described in detail:

[0035] Such as figure 1 As shown, the present invention includes a first operating platform 100, a second operating platform 200 and a third operating platform 300 arranged from bottom to top, and a second hydraulic pressure sensor 1200, a diversion valve 1600 and a diversion valve 1600 are installed on the first operating platform 100. A flow pump 1700 , a thermostatic bottle 400 and an erosion device 1400 are installed on the second operating platform 200 , and a centrifugal pump 900 and a two-phase valve 1000 are installed on the third operating platform 300 .

[0036]The outlet port of the reagent bottle 500 is connected to the first inlet port of the buffer bottle 800 through the dosing pump 600 and the check valve 700 in turn, and the outlet port of the buffer bottle 800 is connected to the first inlet port of the two-phase valve 1000 through the centrifugal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com