Method for processing m50nil bearing steel, strengthening m50nil bearing steel and bearing

A technology for bearing steel and bearings, applied in the direction of solid-state diffusion coating, vacuum evaporation coating, coating, etc., can solve the problems of unsatisfactory bearing strength and contact fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

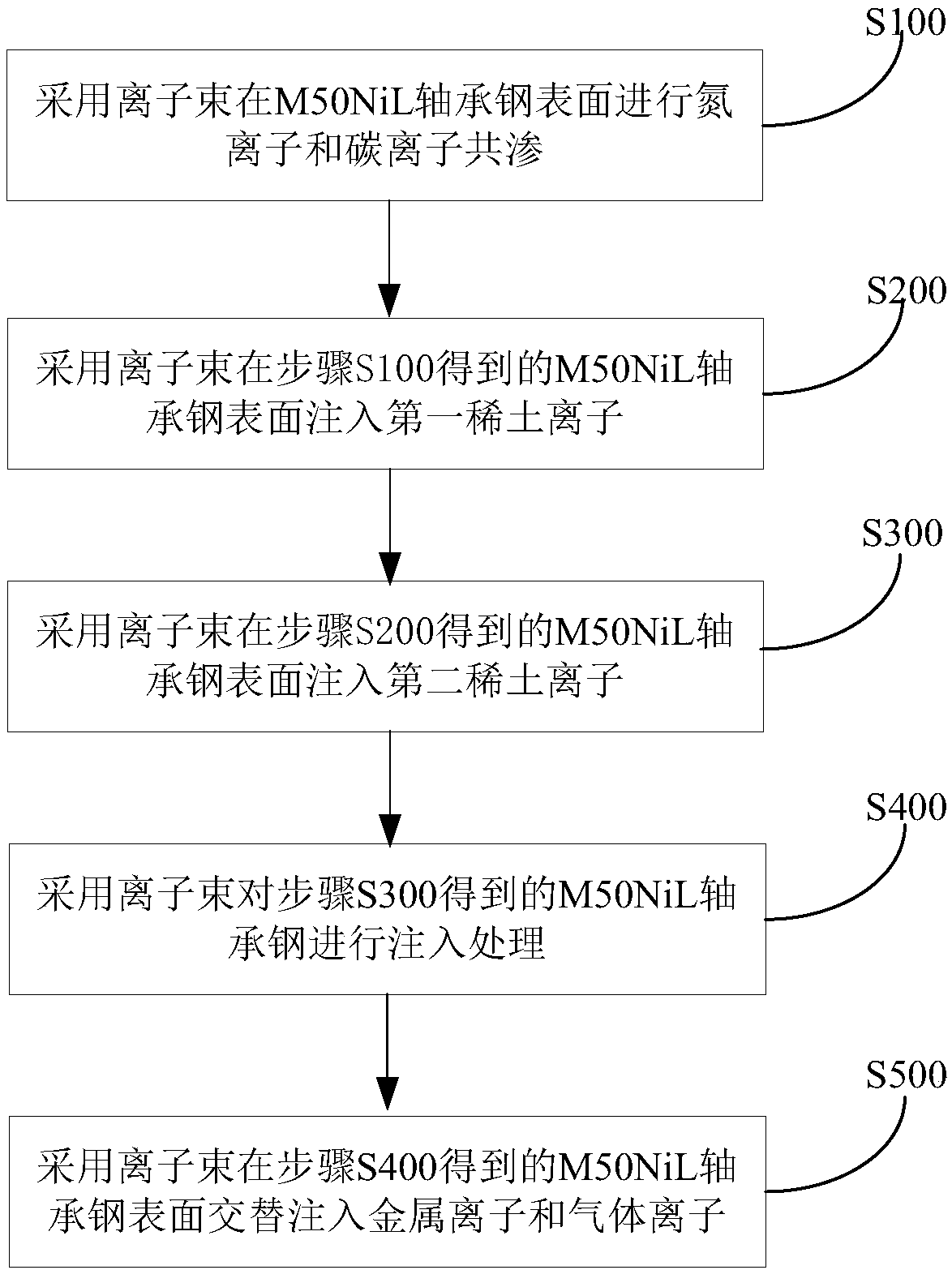

Method used

Image

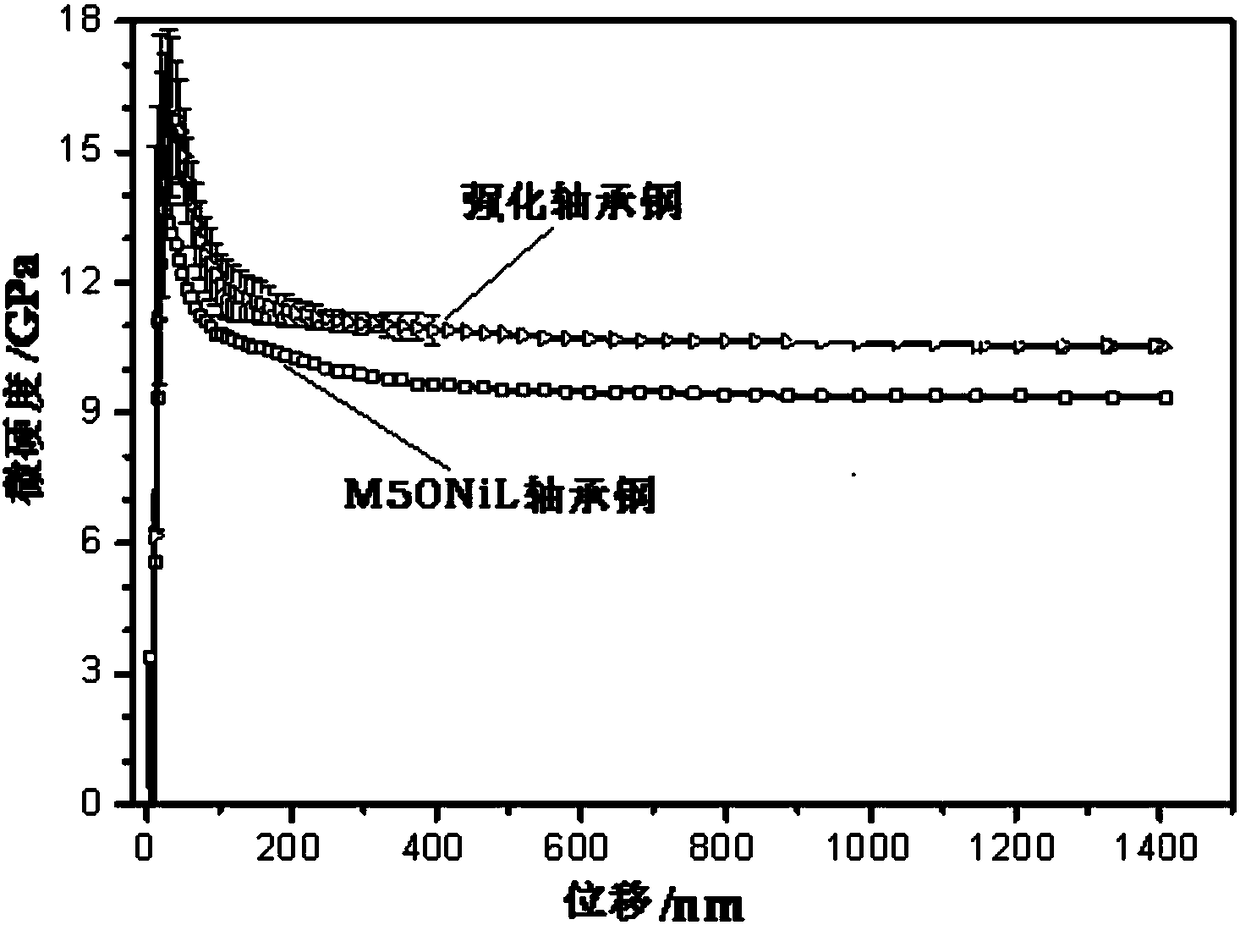

Examples

Embodiment 1

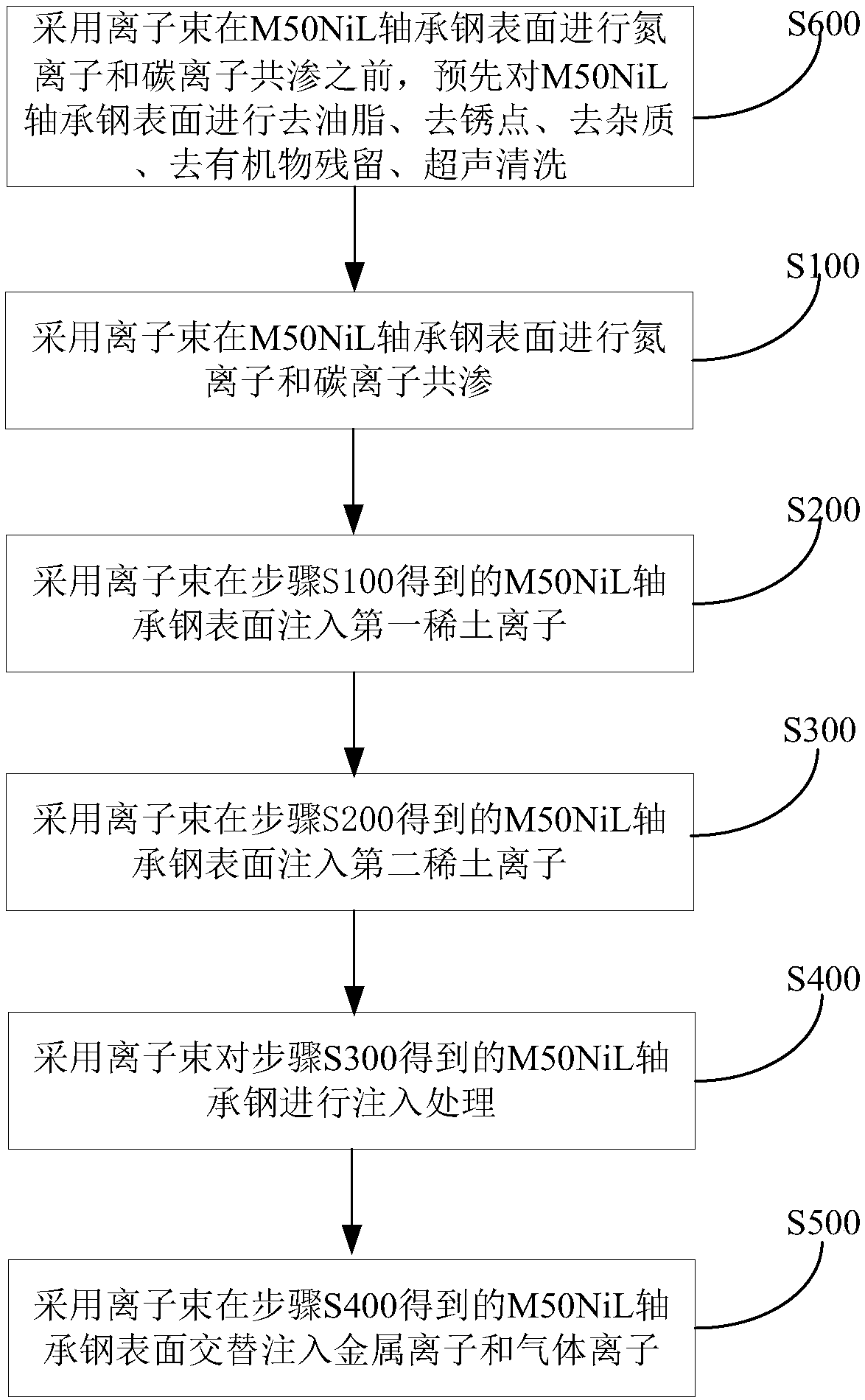

[0060] First, use metal degreasing solvent to remove the grease on the M50NiL bearing steel material, so that there is no grease on the surface, then put the M50NiL bearing steel material to be treated in non-polluting tetrachlorethylene for 30 minutes, take it out, and use rice paper to absorb the residue After the solvent is removed, wipe it with clean silk; then soak and clean the M50NiL bearing steel material with metal derusting solvent for 20 minutes to remove the rust spots on the surface of the material; then put it in acetone, ultrasonically clean it for 20 minutes, take it out and wipe it with a clean silk cloth Dry; then put the M50NiL bearing steel material into alcohol, ultrasonically clean it for 20 minutes, take it out, and dry it with a clean silk cloth. Impurities remain, and at the same time do not use the contaminated or soaked silk cloth to wipe the test piece. Finally, put the treated M50NiL bearing steel into deionized water, take it out after ultrasonic c...

Embodiment 2

[0062] First, use metal degreasing solvent to remove the grease on the M50NiL bearing steel material, so that there is no grease on the surface, then put the M50NiL bearing steel material to be treated in non-polluting tetrachlorethylene for 20 minutes, take it out, and use rice paper to absorb the residue After the solvent is removed, wipe it with clean silk; then soak and clean the M50NiL bearing steel material with metal derusting solvent for 20 minutes to remove the rust spots on the surface of the material; then put it in acetone, ultrasonically clean it for 25 minutes, take it out and wipe it with a clean silk cloth Dry; then put the M50NiL bearing steel material into alcohol, ultrasonically clean it for 25 minutes, take it out, and dry it with a clean silk cloth. When drying, wipe it in the same direction on the smooth surface of the material to ensure that there is no water stain and Impurities remain, and at the same time do not use the contaminated and soaked silk clo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com