Method for synthesizing segmented copolymer by coupling enzymatic catalysis and organic catalysis by virtue of micro reactor

A block copolymer and microreactor technology, which is applied in biochemical equipment and methods, bioreactor/fermenter combinations, specific-purpose bioreactors/fermenters, etc., can solve the problem of low conversion rate and reaction efficiency. Low problems, to achieve the effect of optimizing the process flow, controllable molecular weight, and improving molecular weight distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

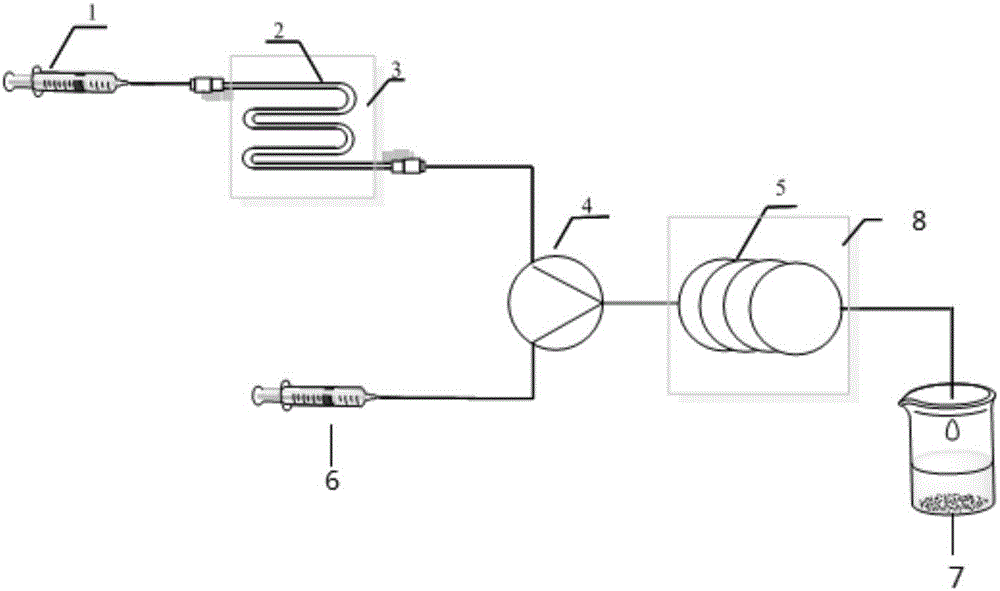

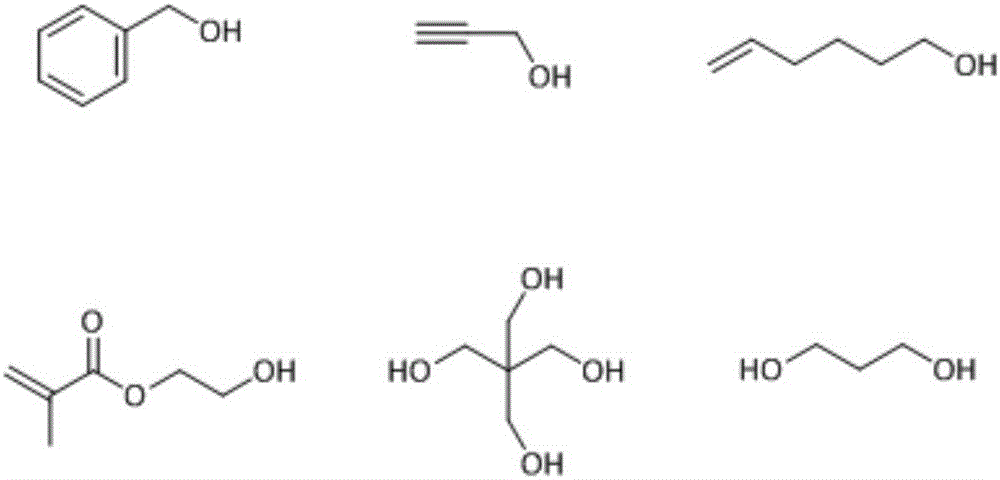

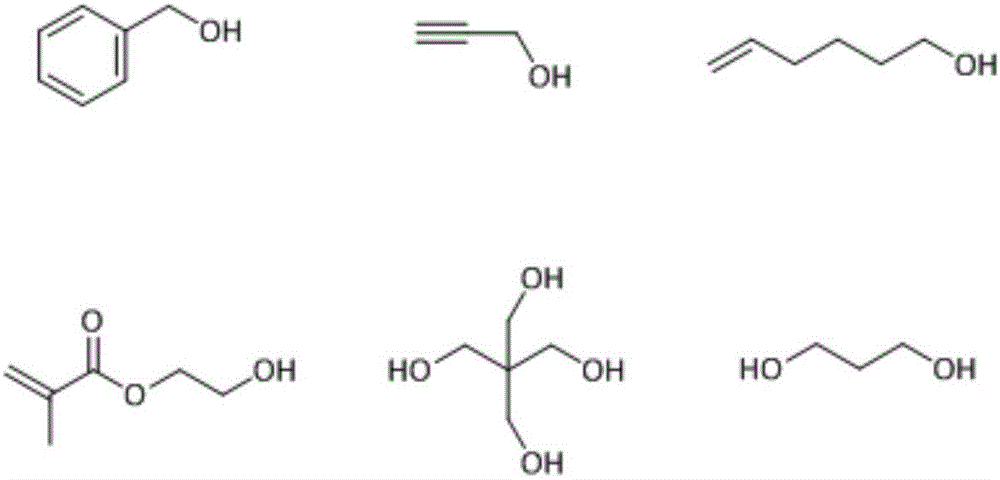

Embodiment 1

[0035]Fill 1.17 g of immobilized enzyme Novozyme 435 with a particle size of 0.3 to 0.9 mm into an immobilized enzyme microreactor with an inner diameter of 3.8 mm and a length of 300 mm (retention volume is 1.81 mL), using an inner diameter of 1 mm and a length of 9218.2 mm microchannel reactor (reserved volume is 7.24mL), connect the device, and flush the pipeline with toluene solvent after redistillation to remove water. Add ε-caprolactone (6.8484g, 6.65mL, 60mmol), benzyl alcohol (0.21mL, 2mmol), toluene (8.14mL) and δ-valerolactone to two flat-bottomed dry ampoules after removing water at high temperature (1.82mL, 20mmol), TBD (0.1mmol), toluene (13.18mL), after shaking and mixing, move them into the first material sampling device A and the second material sampling device B, and adjust the flow rate of A and B to be 0.362ml / min, the reaction temperatures in the two reactors were 60°C and 25°C respectively, and the reaction was started. After 25min, the reaction was stabl...

Embodiment 2

[0037] Fill 1.17 g of immobilized enzyme Novozyme 435 with a particle size of 0.3 to 0.9 mm into an immobilized enzyme microreactor with an inner diameter of 3.8 mm and a length of 300 mm (retention volume is 1.81 mL), using an inner diameter of 1 mm and a length of 18436.4 mm microchannel (retention volume is 14.48mL), connect the device, and flush the pipeline with toluene solvent after redistillation to remove water. Add ε-caprolactone (6.65mL, 60mmol), benzyl alcohol (0.21mL, 2mmol), 8.14mL toluene and δ-valerolactone (5.44mL, 60mmol ), 0.3mmol TBD, 9.56mL toluene, oscillated and mixed evenly, and moved into the first material sampling device A and the second material sampling device B, the flow rate of A and B was adjusted to 0.362ml / min, and the reaction temperature was 60°C and 25°C, start the reaction, wait for 25 minutes to stabilize the reaction, collect for 6 minutes, add 80mL of methanol and quencher solid benzoic acid (0.13mmol), stir and precipitate at low temper...

Embodiment 3

[0039] Fill 0.585 g of immobilized enzyme Novozyme 435 with a particle size of 0.3 to 0.9 mm into an immobilized enzyme microreactor with an inner diameter of 3.8 mm and a length of 150 mm (retention volume is 0.905 mL), using an inner diameter of 1 mm and a length of 3687 mm The microchannel reactor (retention volume is 2.90mL), connect the device, and flush the pipeline with the toluene solvent after distilling off the water. Add ε-caprolactone (6.65mL, 60mmol), benzyl alcohol (0.21mL, 2mmol), 8.14mL toluene and lactide (20mmol), DBU (0.02 mL, 0.1mmol), 14.98mL toluene, after shaking and mixing, move into the first material sampling device A and the second material sampling device B, control the flow rate of A and B to be 0.181ml / min, the reaction in the two reactors The temperature was 60°C and 25°C respectively, and the reaction was started. After 44 minutes, the reaction was stable and collected for 11 minutes. Then, 80 mL of methanol and 0.04 mmol of solid benzoic acid (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com