Method for reducing olefin content of catalytically cracked gasoline

A technology for catalytically cracking gasoline and olefin content, applied in the gasoline field, can solve the problems of reducing the olefin content of light gasoline fractions, unable to react with normal olefins, reducing the olefin content, etc. economic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

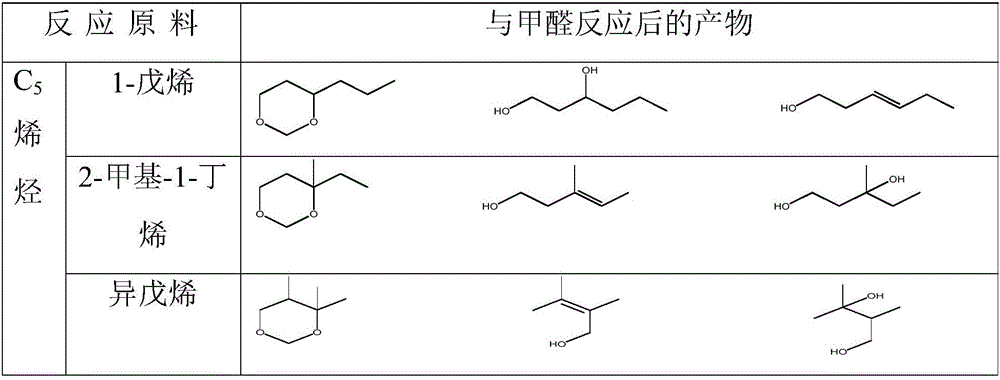

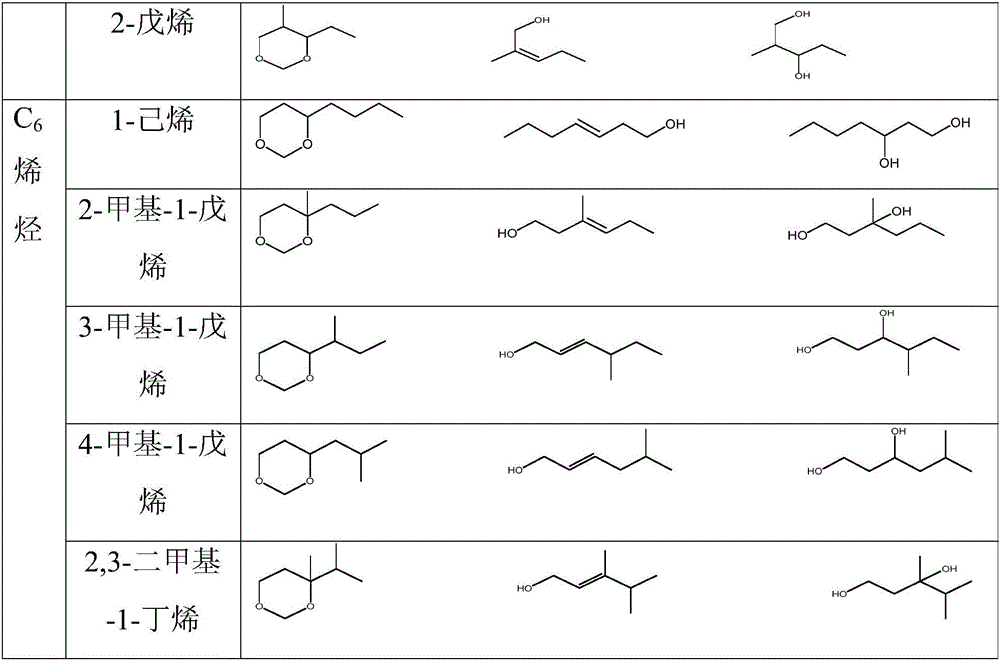

Method used

Image

Examples

Embodiment 1

[0028] First, catalytic cracking (FCC) light gasoline (C 5 +C 6 ) fraction and the mass percentage concentration are 37% formaldehyde aqueous solution to join in the slurry bed reactor according to the mass ratio of 6:1, then add account for catalytic cracking (FCC) light gasoline (C 5 +C 6 ) fraction and mass percentage concentration are 37% formaldehyde aqueous solution gross mass 1% strongly acidic styrene series cation exchange resin as catalyst, feed nitrogen, and keep the pressure of nitrogen to be 1.0MPa, control the temperature of slurry bed reactor The temperature is 100°C, the rotation speed is 400r / min, and the reaction time is 6h;

[0029] Next, the product after the above-mentioned reaction for 6 hours is subjected to purification treatment; the purification treatment is specifically: the product after the above-mentioned reaction for 6 hours is subjected to deacidification treatment, formaldehyde removal treatment and rectification dehydration treatment in sequ...

Embodiment 2

[0031] First, catalytic cracking (FCC) light gasoline (C 5 +C 6 ) fraction and mass percent concentration are 85% formaldehyde aqueous solution to join in the slurry bed reactor according to the mass ratio of 10:1, then add account for catalytic cracking (FCC) light gasoline (C 5 +C 6 ) fraction and mass percent concentration are 37% formaldehyde solution gross mass 4% H-Y molecular sieve as catalyzer, feed nitrogen, and keep the pressure of nitrogen to be 0.1MPa; The temperature of control slurry bed reactor is 140 ℃, and the rotating speed is 500r / min, reaction 6h;

[0032] Next, the product after reacting for 6 hours is purified to finally obtain a catalytic cracking (FCC) light gasoline product with reduced olefin content. Among them, the conversion rate of formaldehyde and catalytic cracking (FCC) light gasoline (C 5 +C 6 ) The conversion rate of olefins in the cut is shown in Table 2.

[0033] In this example, the same purification process as in Example 1 is used f...

Embodiment 3

[0035] First, catalytic cracking (FCC) light gasoline (C 5 +C 6 ) fraction and paraformaldehyde are added in the slurry bed reactor according to the mass ratio of 22:1, then add account for catalytic cracking (FCC) light gasoline (C 5 +C 6 ) fraction and 4% H-beta molecular sieve of paraformaldehyde gross mass as catalyst, feed nitrogen, and keep the pressure of nitrogen to be 1.0MPa, the temperature of control slurry bed reactor is 200 ℃, and the rotating speed is 600r / min, reaction 2h;

[0036] Next, the product after reacting for 2 hours is purified to finally obtain a catalytic cracking (FCC) light gasoline product with reduced olefin content. Among them, the conversion rate of formaldehyde and catalytic cracking (FCC) light gasoline (C 5 +C 6 ) The conversion rate of olefins in the cut is shown in Table 2.

[0037] In this example, the same purification process as in Example 1 is used for purification treatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com