Dendritic polyether clay shale inhibitor and preparation method and application thereof

A dendritic and inhibitor technology is applied in the field of dendritic polyether shale inhibitor and its preparation, and mud shale inhibitor for drilling fluid, which can solve the problems of drilling fluid foaming, large addition, and viscosity increase. , to achieve the effect of inhibiting hydration and dispersion, highlighting inhibition performance, and not easy to desorb

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

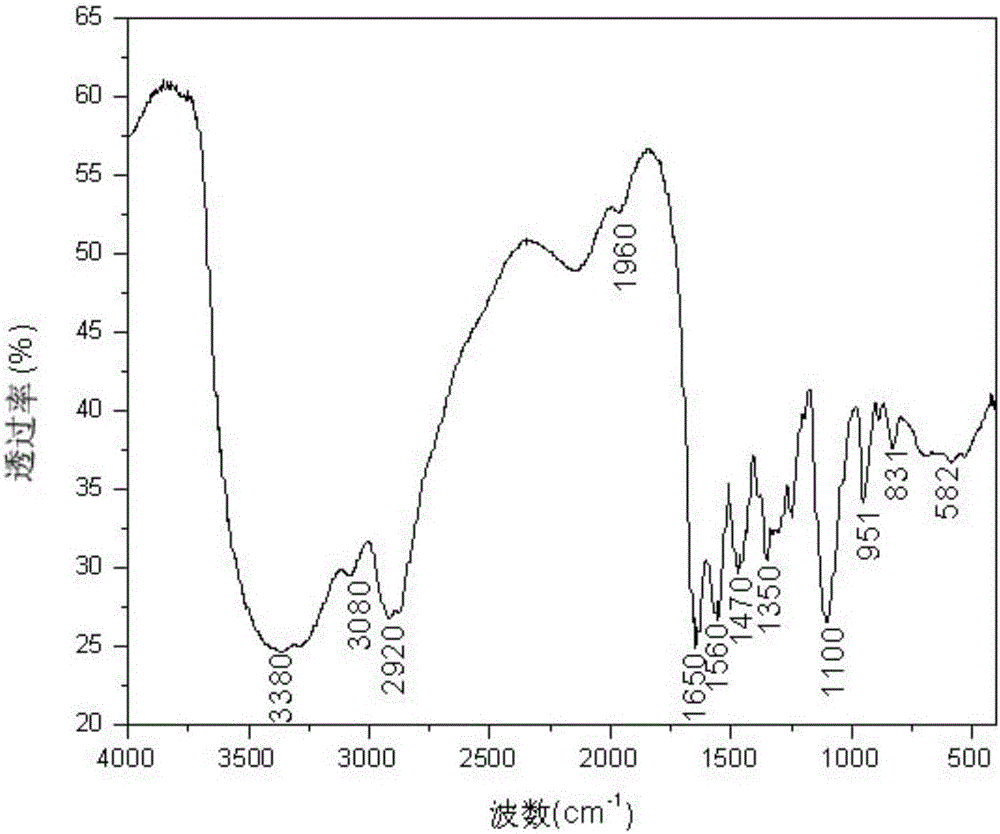

Embodiment 1

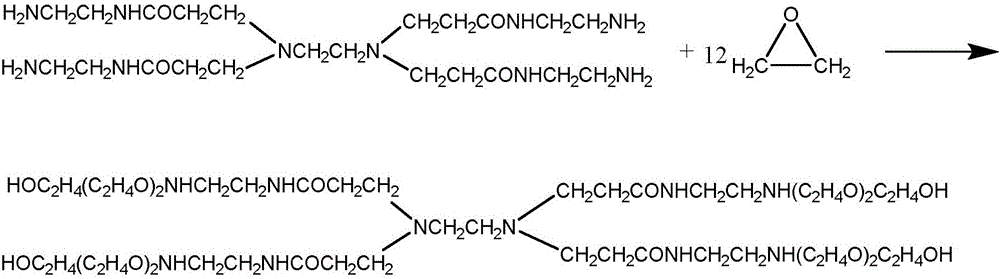

[0052] Add 0.1mol (51.6g) initiator GOPAMAM (ethylenediamine as the core) polyamide-amine dendritic polymer and 0.2g potassium hydroxide in a 250mL high-temperature and high-pressure reactor, and purge the pipeline with nitrogen gas after sealing and react kettle 3 times, and then vacuumize the inside of the reactor. Heat the reaction kettle, and when the temperature rises to 80°C, slowly add 1.2mol (52.8g) of ethylene oxide through the metering tank, and add all the ethylene oxide in 10 minutes. After all the ethylene oxide was added, the temperature was raised to 110°C and the temperature was kept stable. When the pressure in the kettle dropped to a constant value, it indicated that the reaction was over. Pass circulating water to cool to room temperature, release the pressure and discharge the material, neutralize the reaction product with acetic acid, desalt by suction filtration, dendritic polyether mud shale inhibitor.

[0053] The synthetic route is as follows:

[005...

Embodiment 2

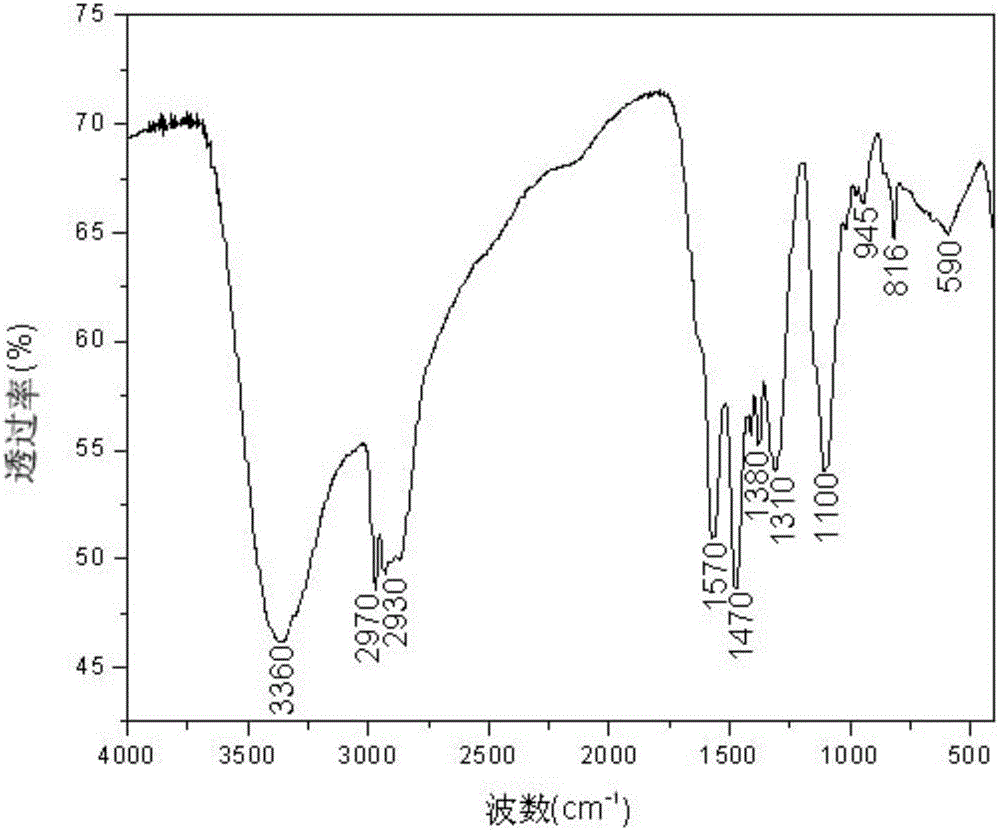

[0058] Add 0.1mol (28.8g) starter GOPPI (ethylenediamine as the core) polypropyleneimine dendritic polymer and 0.1g potassium hydroxide in a 250mL high-temperature and high-pressure reactor, and purge the pipeline and reaction with nitrogen gas after sealing. kettle 3 times, and then vacuumize the inside of the reactor. Heat the reaction kettle, and when the temperature rises to 70°C, slowly add 0.8mol (46.4g) of propylene oxide through the metering tank. After all the addition is completed within 10 minutes, the temperature is raised to 130°C and the temperature is kept stable. When the pressure in the reactor does not change any more, cool down to about 60°C with circulating water, then add 0.8mol (35.2g) of ethylene oxide through the metering tank, and after adding all of it within 10 minutes, raise the temperature to 110°C and keep the temperature stable . As the reaction proceeds, the pressure in the reactor drops, and when the pressure drops to a constant value, it indi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com