Anti-vibration environmental-protection nano film package material and preparation technology thereof

A nano-film and packaging material technology, applied in the field of nano-materials, can solve the problems of expansion flame retardant PPHRR decline and other problems, achieve the effect of improving low temperature resistance, good synergistic effect, and enhanced temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

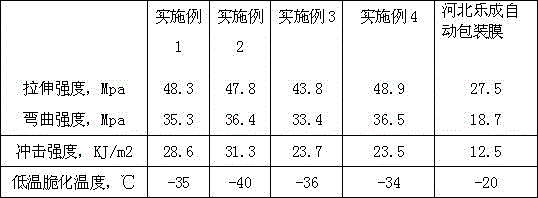

Examples

Embodiment 1

[0024] A kind of anti-seismic and environment-friendly nano-film packaging material and its preparation process

[0025] An anti-shock environment-friendly nano-film packaging material, which includes the following components: 1 weight part of nitrile rubber, 15 parts of urotropine, 5 parts of vacuum residue, and 15 parts of polylactic acid chitosan 10 parts by weight of nano-graphene, 20 parts by weight of PVC resin, 20 parts by weight of PFA resin, 10 parts by weight of triglyceride trimellitate, 5 parts by weight of tetraethylene glycol diheptanoate, p-toluenesulfonyl semicarbazide 6 parts by weight, 8 parts by weight of fluorocarbon-based silicone oil, 6 parts by weight of 4,4'-oxybisbenzenesulfonyl hydrazide, 6 parts of pitch-based carbon fiber powder, 5 parts of triethyl phosphate, 8 parts of hexamethylenetetramine, 2 parts of trimethylpentyltriethoxysilane, 0.3 parts by weight of conductive mica powder, 0.2 parts by weight of conductive graphite powder, 0.8 parts by wei...

Embodiment 2

[0035] A kind of anti-seismic and environment-friendly nano-film packaging material and its preparation process

[0036] An anti-shock environment-friendly nano-film packaging material, which includes the following components: 1 weight part of nitrile rubber, 10 parts of phenolic resin, 20 parts of urotropine, 10 parts of vacuum residue, polylactic acid 20 parts by weight of chitosan, 15 parts by weight of nano-graphene, 30 parts by weight of PVC resin, 20 parts by weight of polyarylsulfone, 25 parts by weight of PFA resin, 15 parts by weight of triglyceride trimellitate, tetraethylene glycol diheptyl 10 parts by weight of acid ester, 12 parts by weight of p-toluenesulfonyl semicarbazide, 14 parts by weight of fluorocarbon-based silicone oil, 14 parts by weight of 4,4'-oxybisbenzenesulfonyl hydrazide, 8 parts of pitch-based carbon fiber powder, non-halogenated organic 7 parts of phosphonate, 10 parts of hexamethylenetetramine, 4 parts of trimethylpentyltriethoxysilane, 0.5 par...

Embodiment 3

[0048] An anti-shock environment-friendly nano film packaging material, which comprises: 1 weight part of nitrile rubber, 9 parts of phenolic resin, 17 parts of hexamethamine, 7 parts of vacuum residue, 18 parts of polylactic chitosan, 12 parts by weight of nanographene, 25 parts by weight of PVC resin, 18 parts by weight of polyarylsulfone, 22 parts by weight of PFA resin, 12 parts by weight of triglyceride trimellitate, 7 parts by weight of tetraethylene glycol diheptanoate, para 8 parts by weight of toluenesulfonyl semicarbazide, 10 parts by weight of fluorocarbon-based silicone oil, 10 parts by weight of 4,4'-oxobisbenzenesulfonyl hydrazide, 32 parts by weight of coal gangue, 0.4 parts by weight of conductive mica powder, and 0.3 parts by weight of nano-conductive graphite powder Parts by weight, 0.9 parts by weight of 2,4 toluene diisocyanate trimer, 32 parts of pitch-based carbon fiber powder, 6 parts of non-halogenated organic phosphinate, 9 parts of hexamethylenetetrami...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com