Carbon nanotube toughened hafnium diboride super-high-temperature ceramic composite material and preparing method thereof

A technology of ultra-high temperature ceramics and hafnium diboride, which is applied in the field of carbon nanotube toughened hafnium diboride ultra-high temperature composite composite materials and its preparation. problems, achieve excellent thermal shock resistance, lower sintering temperature, and suppress abnormal grain growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

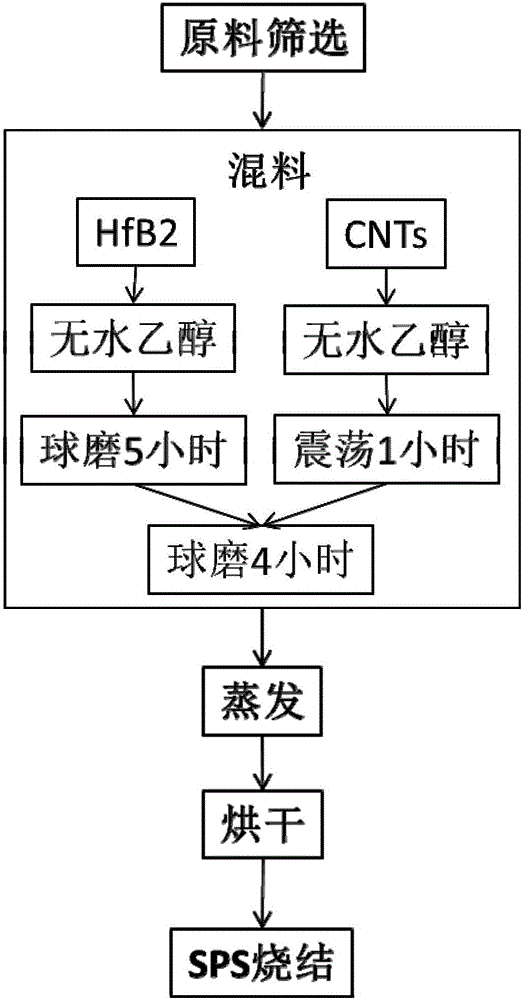

[0038] In a first aspect, the present invention provides a method for preparing a carbon nanotube / hafnium diboride ultra-high temperature ceramic composite material, the method comprising the following steps:

[0039] S1: mixing step, mixing hafnium diboride matrix powder and carbon nanotube powder to obtain a mixed powder of hafnium diboride and carbon nanotube;

[0040] S2: a sintering step, the mixed powder is sintered by a spark plasma sintering method to obtain a carbon nanotube toughened hafnium diboride ceramic composite material.

[0041] In some preferred embodiments, in order to mix the hafnium diboride matrix powder and the carbon nanotube powder uniformly, the S1 step may include:

[0042] S11: a mixing step, mixing and drying the hafnium diboride matrix powder and the carbon nanotube powder to obtain a dried mixed powder; and

[0043] S12: Grinding, grinding the dried mixed powder to obtain a ground mixed powder.

[0044] It is generally believed that the smaller ...

Embodiment 1

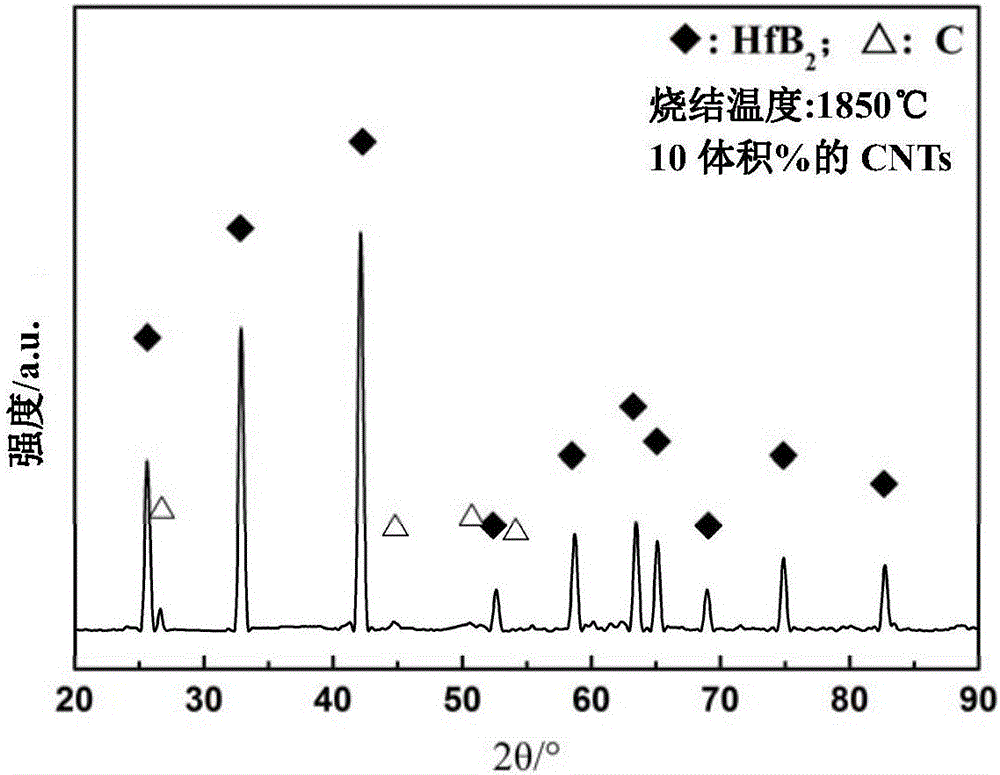

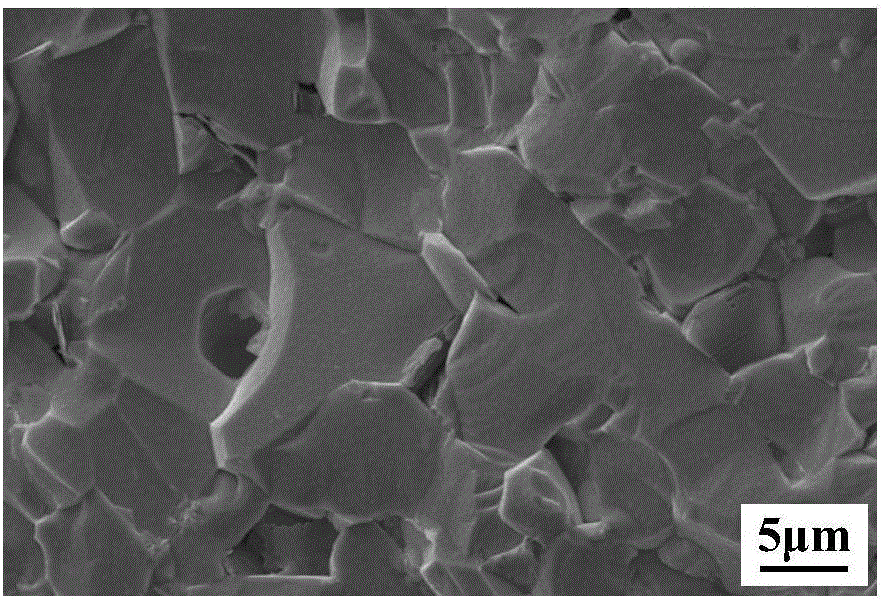

[0065] Weigh the hafnium diboride matrix powder with an average particle size of 1 micron and the carbon nanotube powder with an average particle size of 50 nanometers according to the required ratio, and then use zirconia balls and absolute ethanol as a dispersion medium to grind the two particles through a planetary ball mill. The hafnium boride matrix powder was ball milled for 5 hours to obtain a hafnium diboride dispersion, wherein the spherical mass ratio was 10:1; in addition, the carbon nanotube powder was dispersed into dehydrated alcohol (500ml of sewage ethanol, carbon nanotube powder and the ratio of dehydrated alcohol is 1:200), utilize ultrasonic vibrator (40KHz, power is 1000W) 1 hour, obtain carbon nanotube dispersion; Mix hafnium diboride dispersion and carbon nanotube dispersion, continue Wet grinding for 4 hours to obtain a composite slurry of hafnium diboride and carbon nanotubes. Subsequently, the composite slurry of hafnium diboride and carbon nanotubes w...

Embodiment 2 to 18

[0068] Except for the content listed in Table 1, others were carried out in the same manner as in Example 1.

[0069] Table 1 The processing conditions of each embodiment and the performance of the prepared carbon nanotube toughened hafnium diboride-based ceramic material

[0070]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com