Electrode for precise electrolytic forming of blade profile and processing method thereof

A technology for forming electrodes and blades, which is applied in the direction of electric processing equipment, electrochemical processing equipment, electrode manufacturing, etc., can solve the problems of not meeting the requirements of mass production, unstable quality, low efficiency, etc., achieve low cost and high processing accuracy , high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further elaborated below in conjunction with the accompanying drawings of the description.

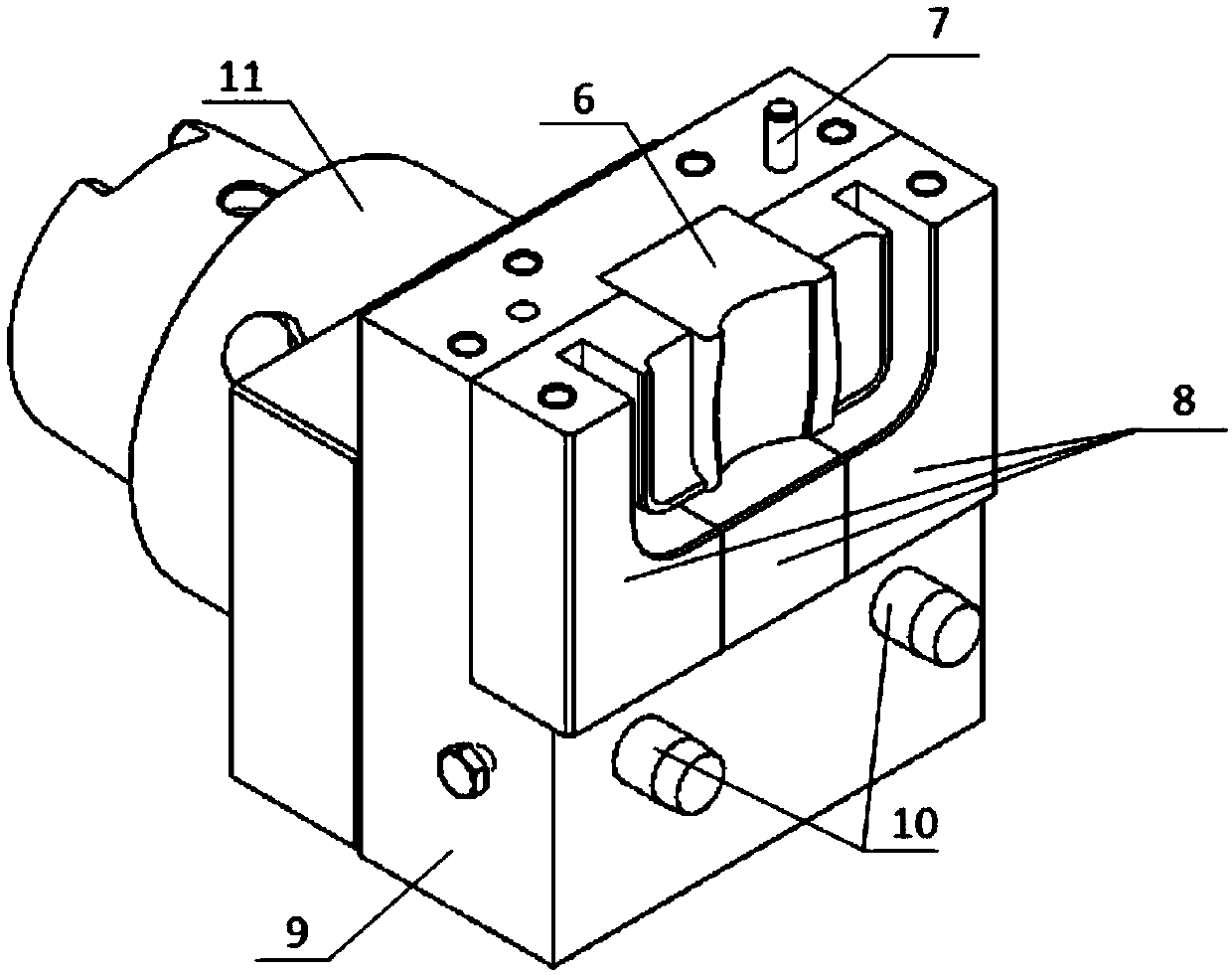

[0036] The invention provides a molding electrode and a process method for precision electrolysis and no-residue processing of stator blade blades without mounting plates of compressors, including a three-dimensional airfoil curved surface working cathode, a sealed and stable flow structure, an electrolyte inlet / outlet, and Special HSK hydraulic chuck, etc. The working cathode is the core tool of the blade forming process. The electrode profile can be designed into different shapes according to the different structures of the blade parts and through the calculation of the gap. The electrolyte flow field adopts the principle of the shortest stroke. The air flows out at the same time, making the processing process more stable and realizing high-efficiency and low-cost processing.

[0037] The present invention is a forming electrode and process metho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com