Method for producing micro-needle array templates based on laser etching technology as well as products and application thereof

A microneedle array and laser etching technology, which is applied in laser welding equipment, surgery, manufacturing tools, etc., can solve the difficulties in mass production and application of microneedle array templates, complicated preparation process of microneedle array templates, poor structural design, etc. problem, to improve the effect of transdermal treatment, improve skin permeability, and easy to cure and form.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

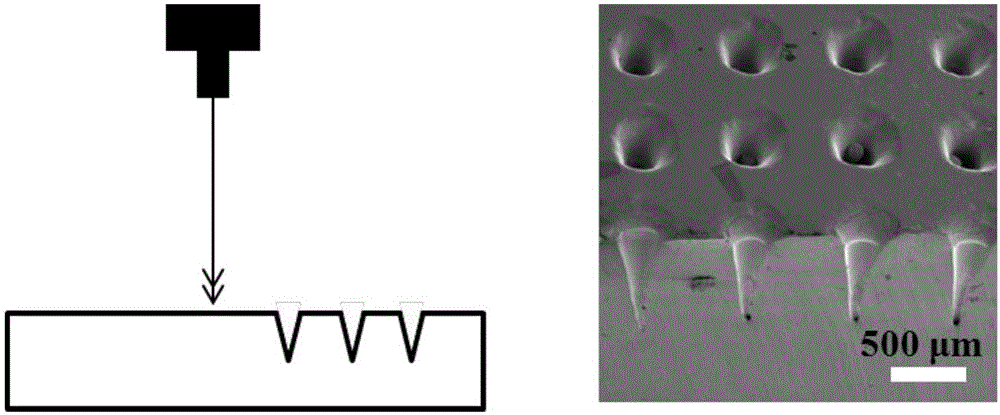

[0038] The preparation method of the microneedle array template prepared by laser etching technology provided by the present invention usually includes the following steps:

[0039] (1) Preparation of PDMS substrate: Put PDMS and its curing agent (such as SYLGARD 184) in a plastic petri dish at a mass ratio of 20:1 to 5:1 and mix them thoroughly. The mass ratio can be preferably 10:1. Vacuumize at 0.08MPa to remove air bubbles in the mixture, heat and solidify at 70-90°C for 1 to 4 hours (or preferably heat and solidify at 80°C for 2 hours), and peel off after cooling;

[0040] (2) Design of laser etching mask: Use engraving machine drawing software to draw a 10×10 concentric circle array with a diameter of 50 to 500 μm and a pitch of 200 to 600 μm; the diameter may preferably be 50 to 300 μm, and more preferably 50 to 250μm, the spacing can be preferably 300-500μm;

[0041] (3) Etching of the microneedle template: Place the PDMS substrate obtained in step (1) horizontally on...

Embodiment 1

[0045] In this embodiment, the microneedle array template prepared based on laser etching technology was prepared according to the following method:

[0046] (1) Preparation of PDMS substrate: Put PDMS and its curing agent (such as SYLGARD 184) in a plastic petri dish at a mass ratio of 10:1 and mix them thoroughly, and vacuumize at -0.08MPa to remove the air bubbles in the mixture, 80 ℃ for heating and curing for 2 hours, and peel off after cooling to obtain the PDMS substrate required for laser etching;

[0047] (2) Design of laser etching mask: Use engraving machine drawing software to draw a 10×10 concentric circle array with a diameter of 150 μm and a pitch of 500 μm; taking any concentric circle in the concentric circle array as an example, the diameter here refers to The diameter corresponding to the circle with the largest diameter, the diameter of the circle with the smallest diameter among the concentric circles may be 50 μm.

[0048] (3) Etching of the microneedle ...

Embodiment 2

[0051] In this embodiment, the microneedle array template prepared based on laser etching technology was prepared according to the following method:

[0052] (1) Preparation of PDMS substrate: Put PDMS and its curing agent in a plastic petri dish at a mass ratio of 10:1 and mix them thoroughly, vacuumize at -0.08MPa to remove air bubbles in the mixture, heat and cure at 80°C for 2h, After cooling, peel off to obtain the PDMS substrate required for laser etching;

[0053] (2) Design of laser etching mask: use engraving machine drawing software to draw a 10×10 concentric circle array with a diameter of 150 μm and a pitch of 500 μm;

[0054] (3) Etching of the microneedle array template: place the PDMS substrate obtained in (1) horizontally on the PL-40 CO 2 In the engraving area of the laser engraving machine, import the mask pattern obtained in (2) into the laser engraving software, set the laser current to 6mA, the laser scanning rate to 10cm / s and the number of laser proce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com