Shot-film flow liquid metal free surface system

A liquid metal, film flow technology, applied in the field of liquid metal free surface systems, can solve problems such as large force and unavailability

Active Publication Date: 2012-04-18

SOUTHWESTERN INST OF PHYSICS

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

If the force is large, the film flow will not move and become turbulent flow, or the flow will become narrower and narrower and become stream flow, which cannot be used

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

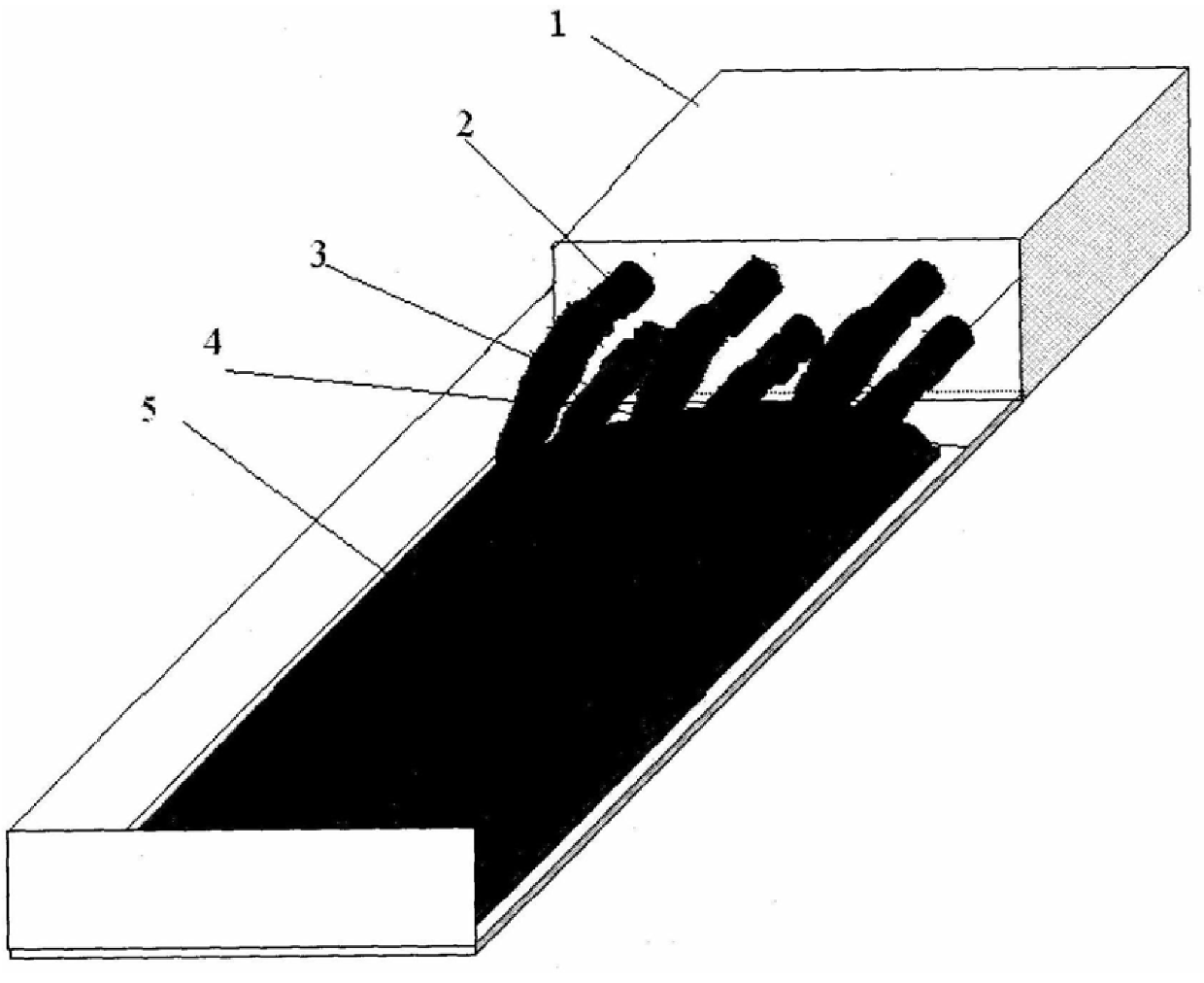

[0010] Below in conjunction with the accompanying drawings, the jet-film flow liquid metal free surface system of the present invention is further described.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention specifically relates to a jet-film flow liquid metal free surface system. It includes a jet generator, a jet nozzle and a jet-film flow bottom plate. The jet generator is a metal cavity. A liquid metal inlet port is provided on one side of the jet generator, and a jet nozzle is provided on the opposite side. The jet generator The bottom side of the jet-film flow base plate is connected, and the jet nozzle is located above the jet-film flow base plate. With this system, by properly adjusting the diameter and arrangement of the jet nozzles and the angle with the jet-film flow bottom plate, a stable and smooth jet-film flow can be obtained.

Description

Shot-film flow liquid metal free surface system technical field The present invention relates to the liquid metal free surface system for tokamak fusion device, be specifically related to a kind of Shot-film flow liquid metal free surface system. Background technique The first wall hanging tile, divertor and limiter of tokamak fusion device are key components of fusion device, requiring it They have high thermal conductivity, low sputtering, and resistance to neutron radiation, that is, the ability to withstand high thermal loads and high neutron fluxes. However, solid-state surfaces It is difficult to meet the high heat load of more than 20 megawatts per square meter, and at the same time, various performances will degrade after neutron irradiation. Therefore, the free surface of liquid metal can bear the surface thermal power density of more than 50 megawatts per square meter, and it is easy to Through the advantages of cyclic renewal and life limitation without ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G21B1/11

Inventor 许增裕潘传杰张秀杰

Owner SOUTHWESTERN INST OF PHYSICS

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com