Power utilization safety supervision and electric energy management system for industrial plant area

A power management system and power system technology, applied in the direction of electrical components, circuit devices, etc., can solve the problems that the relevant configuration cannot be customized and modified, and the electrical fault protection is not very comprehensive.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

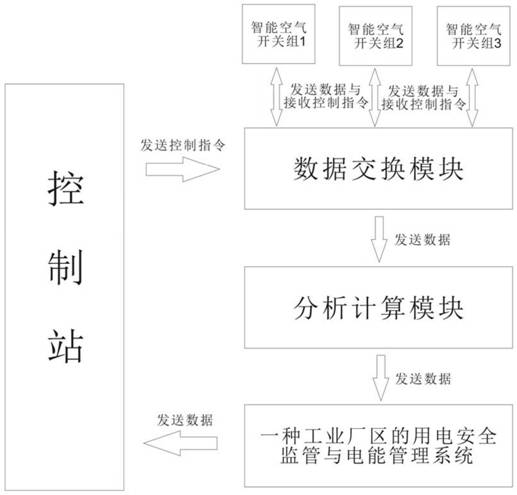

[0049] S1: The data exchange module obtains the real-time operation data of the power system, and the obtained real-time operation data of the power system will be displayed on the screen of the control station;

[0050] S2: The analysis and calculation module obtains real-time measurement data of the power system, including power consumption current, voltage, leakage current, and switch temperature;

[0051] S3: The analysis and calculation module detects whether the power system has leakage, short circuit, overcurrent, overload, overvoltage, undervoltage, lightning surge, abnormal temperature, etc. by comparing the real-time measurement data of the power system fed back by the data exchange module, and analyzes the calculation module The detection items determine that the working state of the power system is abnormal, and judge that the working state of the power system is a fault, and the fault content is leakage, and the leakage location is the area to which the intelligent...

Embodiment 2

[0055] S1: The data exchange module obtains the real-time operation data of the power system, and the obtained real-time operation data of the power system will be displayed on the screen of the control station;

[0056] S2: The analysis and calculation module obtains real-time measurement data of the power system, including power consumption current, voltage, leakage current, and switch temperature;

[0057] S3: The analysis and calculation module detects whether there is leakage, short circuit, overcurrent, overload, overvoltage, undervoltage, lightning surge, abnormal temperature, etc. in the power system by comparing the real-time measurement data of the power system fed back by the data exchange module, and performs leakage Guaranteed function self-inspection, power limit, online detection of power calculation; analysis and calculation module detection items to judge the working status of the power system as normal, and judge the working status of the power system as norma...

Embodiment 3

[0060] S1: The data exchange module obtains the real-time operation data of the power system, and the obtained real-time operation data of the power system will be displayed on the screen of the control station;

[0061] S2: The analysis and calculation module obtains real-time measurement data of the power system, including power consumption current, voltage, leakage current, and switch temperature;

[0062] S3: The analysis and calculation module detects whether there is leakage, short circuit, overcurrent, overload, overvoltage, undervoltage, lightning surge, abnormal temperature, etc. in the power system by comparing the real-time measurement data of the power system fed back by the data exchange module, and performs leakage Guaranteed function self-inspection, power limit, online detection of power calculation; analysis and calculation module detection items to judge the working status of the power system as normal, and judge the working status of the power system as normal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com