Preparation method of quasi isotropic magnetic core film

A quasi-isotropic, magnetic core technology, applied in the application of magnetic film to substrate, magnetic film, inductor/transformer/magnet manufacturing, etc. High permeability, satisfying the effect of integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

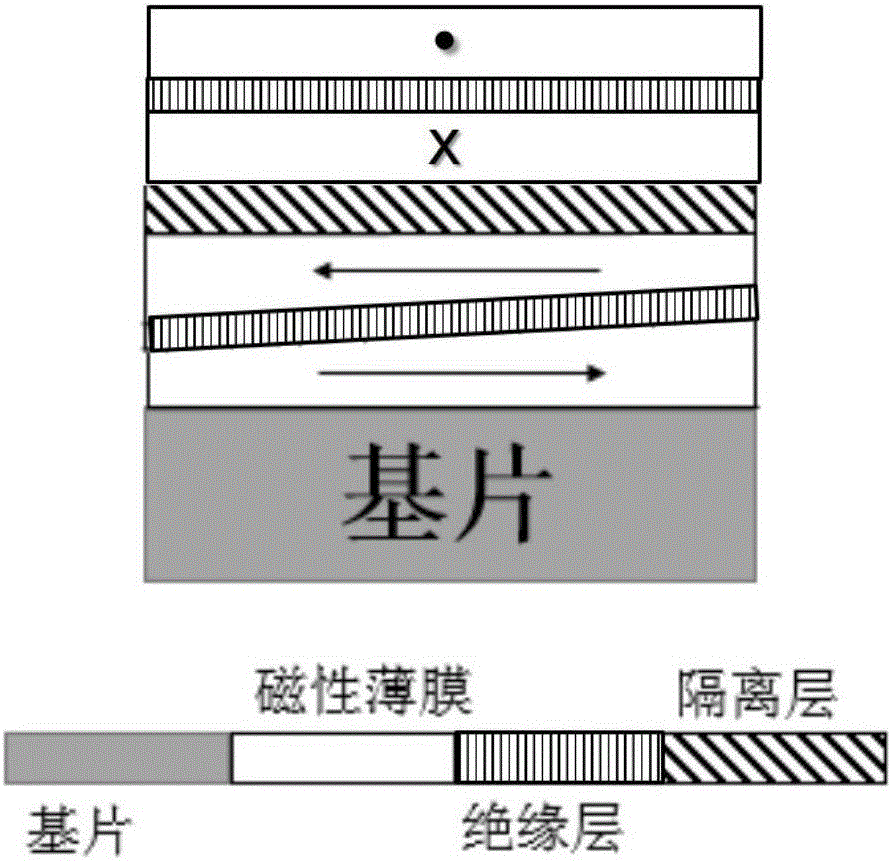

[0030] A preparation method of a quasi-isotropic FeCoTiO nanoparticle magnetic core film, specifically comprising the following steps:

[0031] Step 1: Use acetone, HCl and H in sequence 2 o 2 Prepared acid solution, NH 3 .H 2 O and H 2 o 2 The prepared alkaline solution, alcohol, and deionized water were used to clean a four-inch monocrystalline silicon substrate, and then dried with nitrogen gas for later use;

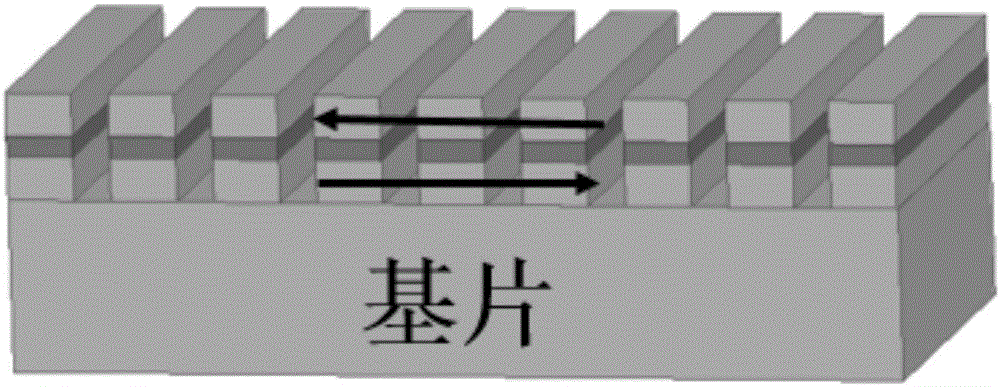

[0032] Step 2: Etch the silicon substrate processed in step 1 to form a stripe-like pattern by photolithography, wherein the length of a single stripe is 2000 μm, the width is 10-40 μm, the spacing between stripes is 40 μm, and the depth of the stripes is 2- 3μm;

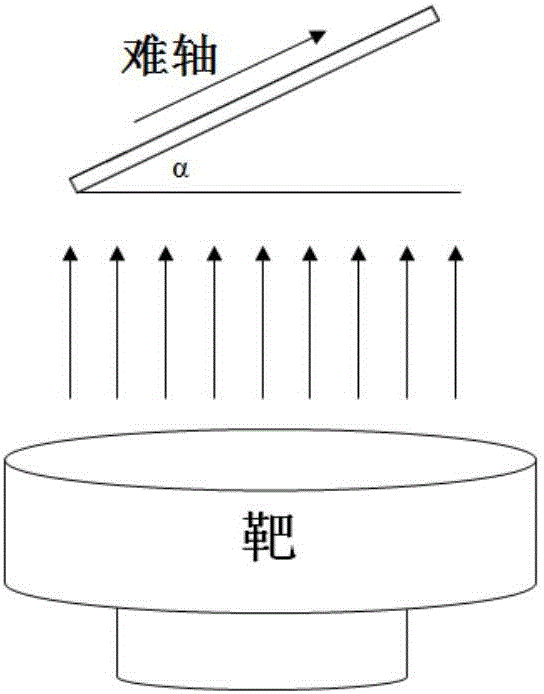

[0033] Step 3: Put the substrate obtained in step 2 into the sputtering chamber, and put the TiO 2 A single wafer is pasted on the surface of a 6-inch FeCo alloy target to form a composite target, which is loaded into target gun A; the SiO 2 Put the target into the target gun B; tilt the substrate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com