Ni-Cr-Mo-W-Nb-Al-Ti system high temperature alloy material, and preparation method and application thereof

A technology of superalloys and alloy materials, which is applied in the field of Ni-Cr-Mo-W-Nb-Al-Ti series superalloy materials, can solve the problems of limited application, limited lasting life, lack of oxidation resistance, etc., and achieve excellent The effect of long-lasting life, excellent oxidation resistance, excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The composition of the alloy is:

[0026] C 0.08; Cr 14.0; Mo 2.75; W 2.75; Nb+Ta 2.75; Al 0.3; Ti 0.4; Fe 5.0; The balance is Ni and unavoidable impurity elements.

[0027] (1) Dosing according to the above-mentioned alloy composition, and then melt in a vacuum induction furnace at a melting temperature of 1450-1470°C, and pour the solution into a consumable electrode;

[0028] (2) remelting and refining the consumable electrode obtained in step (1) in a vacuum consumable furnace, and remelting it into an electroslag ingot;

[0029] (3) heating the electroslag ingot obtained in step (2) to 1240-1260°C, keeping it warm for 3-5 hours, starting forging temperature ≥ 1200°C, stopping forging temperature ≥ 1010°C;

[0030] (4) Air-cool to room temperature after forging, and then carry out surface treatment;

[0031] (5) Heat treatment: solid solution at 980-1150°C, air cooling to obtain the required alloy material.

Embodiment 2

[0033] The composition of the alloy is:

[0034] C 0.07; Cr 16.0; Mo 3.25; W 3.25; Nb+Ta 3.25; Al 0.6; Ti 0.7; Fe 9.0; It is Ni and inevitable impurity elements.

[0035] (1) Dosing according to the above-mentioned alloy composition, and then melt in a vacuum induction furnace at a melting temperature of 1450-1470°C, and pour the solution into a consumable electrode;

[0036] (2) remelting and refining the consumable electrode obtained in step (1) in a vacuum consumable furnace, and remelting it into an electroslag ingot;

[0037] (3) heating the electroslag ingot obtained in step (2) to 1240-1260°C, keeping it warm for 3-5 hours, starting forging temperature ≥ 1200°C, stopping forging temperature ≥ 1010°C;

[0038] (4) Air-cool to room temperature after forging, and then carry out surface treatment;

[0039] (5) Heat treatment: solid solution at 980-1150°C, air cooling to obtain the required alloy material.

Embodiment 3

[0041] The composition of the alloy is:

[0042] C 0.08; Cr 14.5; Mo 3.00; W 3.00; Nb+Ta 3.00; Al 0.4; Ti 0.5; Fe 7.0; Zr0.01; B 0.004; Mg 0.02; Mn 0.55; It is Ni and inevitable impurity elements.

[0043] (1) Dosing according to the above-mentioned alloy composition, and then melt in a vacuum induction furnace at a melting temperature of 1450-1470°C, and pour the solution into a consumable electrode;

[0044] (2) remelting and refining the consumable electrode obtained in step (1) in a vacuum consumable furnace, and remelting it into an electroslag ingot;

[0045] (3) heating the electroslag ingot obtained in step (2) to 1240-1260°C, keeping it warm for 3-5 hours, starting forging temperature ≥ 1200°C, stopping forging temperature ≥ 1010°C;

[0046] (4) Air-cool to room temperature after forging, and then carry out surface treatment;

[0047] (5) Heat treatment: solid solution at 980-1150°C, air cooling to obtain the required alloy material.

PUM

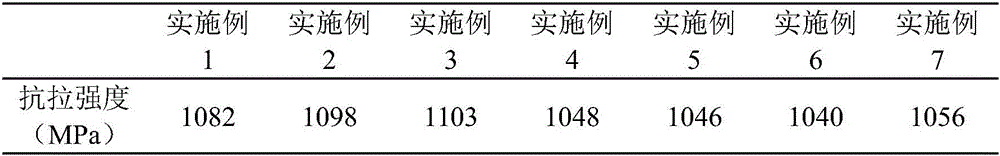

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com