Sugarcane filtered mud fermentation agent and sugarcane filtered mud fermentation method

A sugarcane filtering mud and fermentation method technology, applied in microorganism-based methods, biochemical equipment and methods, bacteria and other directions, can solve the problems of low maximum temperature, incomplete decomposing, long fermentation period, etc. The effect of complete fermentation and long high temperature time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

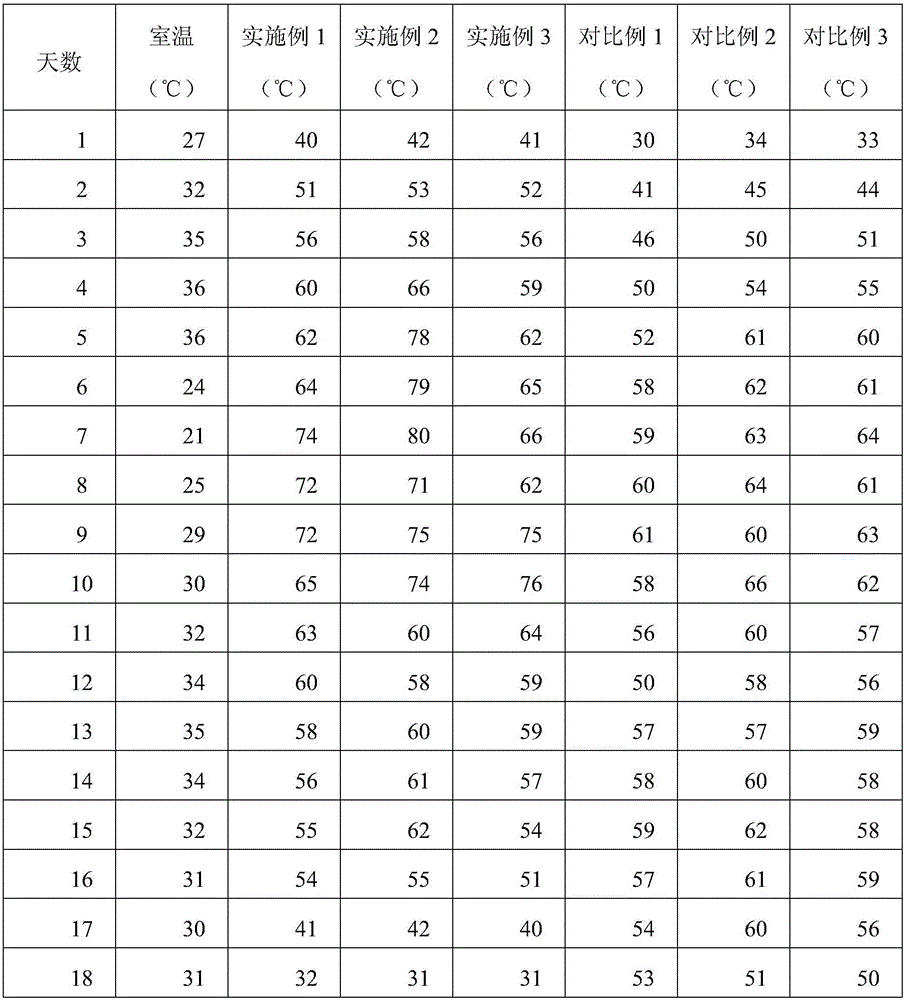

Embodiment 1

[0045] The sugarcane filter mud fermentation agent includes Bacillus subtilis, Aspergillus oryzae, saccharomyces and Trichoderma longosum, and the mass ratio of Bacillus subtilis, Aspergillus oryzae, yeast and Trichoderma longoside is 14:11:6:4. The fermented bacterial agent of sugarcane filter mud is 0.5% of the total amount of sugarcane filter mud, and chicken manure is 9% of the total amount of sugarcane filter mud.

[0046] The chicken manure, the sugarcane filter mud fermentation agent and the sugarcane filter mud with a total weight of 9% of the sugarcane filter mud are mixed evenly, and then mixed with the remaining sugarcane filter mud. Wherein remaining sugarcane filter mud adds 20% chaff. After stirring evenly, the moisture of the sugarcane filter mud is 58%.

[0047] Pile the stirred filter mud into a long strip with a height of 0.5 meters and a width of 1 meter. When the compost temperature reaches 45°C, turn the compost once in the morning and evening.

Embodiment 2

[0049] The sugarcane filter mud fermentation agent includes Bacillus subtilis, Aspergillus oryzae, saccharomyces and Trichoderma longosum, and the mass ratio of Bacillus subtilis, Aspergillus oryzae, yeast and Trichoderma longoside is 15:10:5:5. The fermented bacterial agent of sugarcane filter mud is 0.8% of the total amount of sugarcane filter mud, and chicken manure is 10% of the total amount of sugarcane filter mud.

[0050] The chicken manure, the sugarcane filter mud fermentation agent and the sugarcane filter mud with a total mass of 10% of the sugarcane filter mud are mixed evenly, and then mixed with the remaining sugarcane filter mud. Wherein the remaining sugarcane filter mud is added with 30% straw powder. After stirring evenly, the moisture of the sugarcane filter mud is 60%.

[0051] Pile the stirred filter mud into a long strip with a height of 0.9 meters and a width of 1.3 meters. When the compost temperature reaches 45°C, turn the compost once in the morning...

Embodiment 3

[0053] The sugarcane filter mud fermentation agent includes Bacillus subtilis, Aspergillus oryzae, saccharomyces and Trichoderma longosum, and the mass ratio of Bacillus subtilis, Aspergillus oryzae, yeast and Trichoderma longoside is 16:9:4:6. The fermented bacterial agent of sugarcane filter mud is 1% of the total amount of sugarcane filter mud, and chicken manure is 11% of the total amount of sugarcane filter mud.

[0054] After taking chicken manure, sugarcane filter mud fermenting agent and sugarcane filter mud with 11% of the total mass of sugarcane filter mud and mixing them evenly, they are mixed evenly with the remaining sugarcane filter mud. Wherein the remaining sugarcane filter mud is added with 30% straw powder. After stirring evenly, the moisture of the sugarcane filter mud is 62%.

[0055] Pile the stirred filter mud into a long strip with a height of 0.9 meters and a width of 1.3 meters. When the compost temperature reaches 45°C, turn the compost once in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com