Anti-burning engine oil and preparation method thereof

An engine oil and base oil technology, applied in the petroleum industry, additives, lubricating compositions, etc., can solve the problems of increased carbon deposition in the combustion chamber, damage to the three-way catalyst, insufficient engine lubrication, etc., to improve power and reduce dry friction. , the effect of increasing antioxidant capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

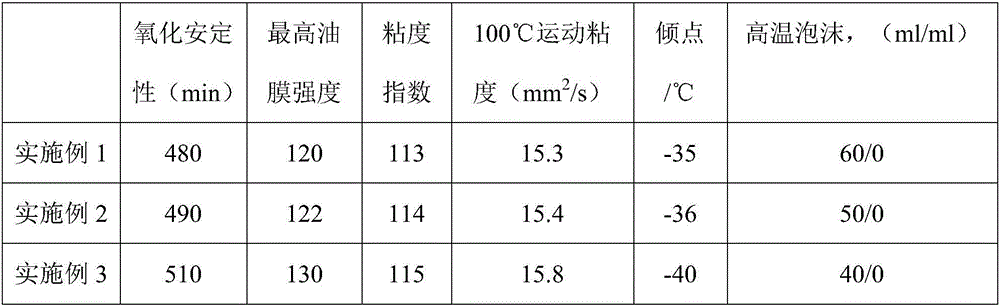

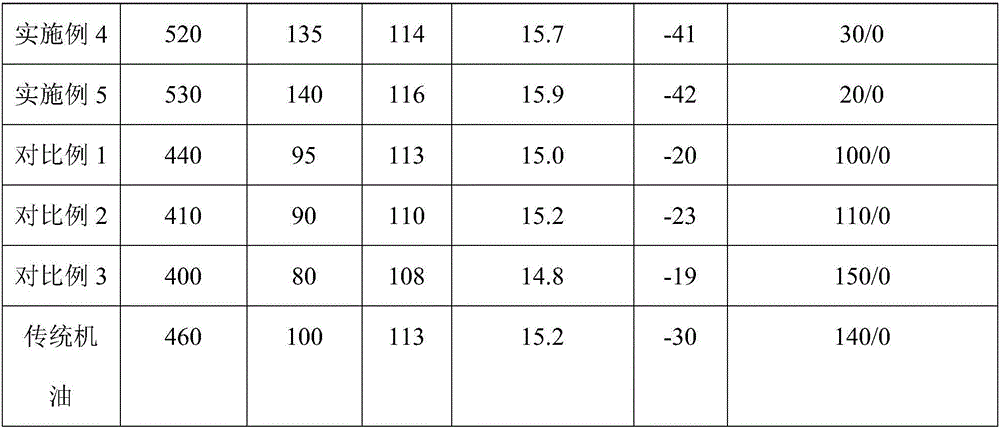

Examples

Embodiment 1

[0018] In the embodiment of the present invention, an anti-burn engine oil is composed of the following raw materials in parts by weight: 1 part of 2,4,6-trichloroisocyanate phenyl, 0.1 part of N-ethylmorpholine, ZSM-5 1.5 parts of molecular sieve, 2.3 parts of liquid polybutadiene, 90 parts of base oil.

[0019] The ZSM-5 molecular sieve was crushed and passed through a 150-mesh sieve to obtain a ZSM-5 molecular sieve powder. The ZSM-5 molecular sieve powder was mixed with hydrogen peroxide solution 3 times its mass, heated and stirred at 52°C for 20min, and then heated to 65°C °C and stirred at this temperature for 30min, then stirred at 71°C for 5h, and then calcined at 400°C for 3h to obtain the treated ZSM-5 molecular sieve, wherein the mass content of hydrogen peroxide contained in the hydrogen peroxide solution is 30%. Mix the treated ZSM-5 molecular sieve with base oil, 2,4,6-trichloroisocyanate phenyl ester, N-ethylmorpholine, and liquid polybutadiene, and ultrasonic...

Embodiment 2

[0021] In the embodiment of the present invention, an anti-burn engine oil is composed of the following raw materials in parts by weight: 1.8 parts of 2,4,6-trichloroisocyanate phenyl, 0.7 parts of N-ethylmorpholine, ZSM-5 2.5 parts of molecular sieve, 3 parts of liquid polybutadiene, 94 parts of base oil.

[0022] The ZSM-5 molecular sieve was crushed and passed through a 150-mesh sieve to obtain a ZSM-5 molecular sieve powder. The ZSM-5 molecular sieve powder was mixed with hydrogen peroxide solution 3 times its mass, heated and stirred at 52°C for 20min, and then heated to 65°C °C and stirred at this temperature for 30min, then stirred at 71°C for 5h, and then calcined at 400°C for 3h to obtain the treated ZSM-5 molecular sieve, wherein the mass content of hydrogen peroxide contained in the hydrogen peroxide solution is 35%. Mix the treated ZSM-5 molecular sieve with base oil, 2,4,6-trichloroisocyanate phenyl ester, N-ethylmorpholine, and liquid polybutadiene, and ultrason...

Embodiment 3

[0024] In the embodiment of the present invention, an anti-burn engine oil is composed of the following raw materials in parts by weight: 1.2 parts of 2,4,6-trichloroisocyanate phenyl, 0.3 parts of N-ethylmorpholine, ZSM-5 1.8 parts of molecular sieve, 2.5 parts of liquid polybutadiene, 91 parts of base oil.

[0025] The ZSM-5 molecular sieve was crushed and passed through a 150-mesh sieve to obtain a ZSM-5 molecular sieve powder. The ZSM-5 molecular sieve powder was mixed with hydrogen peroxide solution 3 times its mass, heated and stirred at 52°C for 20min, and then heated to 65°C °C and stirred at this temperature for 30min, then stirred at 71°C for 5h, and then calcined at 400°C for 3h to obtain the treated ZSM-5 molecular sieve, wherein the mass content of hydrogen peroxide contained in the hydrogen peroxide solution is 32%. Mix the treated ZSM-5 molecular sieve with base oil, 2,4,6-trichloroisocyanate phenyl ester, N-ethylmorpholine, and liquid polybutadiene, and ultras...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com