Non-asphaltic pressure-sensitive self-adhesive glue and waterproof roll material prepared from same

A non-asphalt, self-adhesive technology, applied in the field of construction waterproof membrane production, can solve the problems of loss of adhesion, poor aging resistance, poor low temperature flexibility, etc., to achieve easy production and construction, good low temperature flexibility, bonding high intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

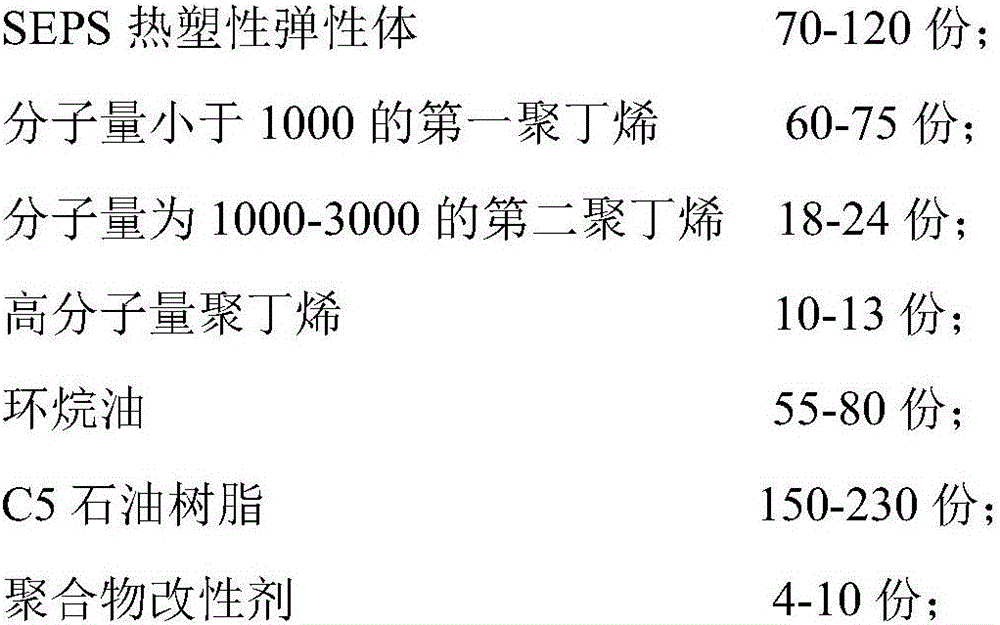

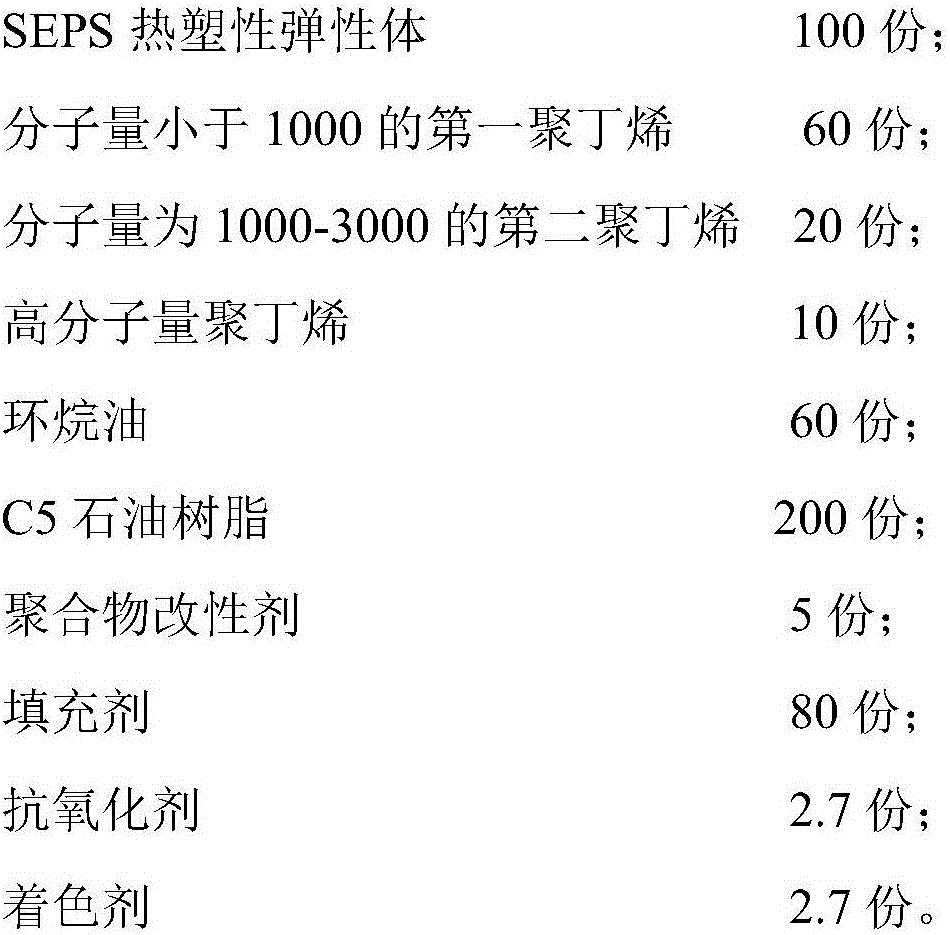

[0034] Non-bituminous pressure-sensitive self-adhesives consist of the following components:

[0035]

[0036] Wherein, the antioxidant is the B225 type antioxidant produced by BASF; the coloring agent is the coloring agent for the coil rubber material produced by BASF, because the coloring agent is only used to adjust the color of the rubber material, it is known to those skilled in the art to select different colors Colorants will produce different coloring effects, so I won't repeat them here.

[0037] Non-bituminous self-adhesive membranes made from non-bituminous pressure-sensitive self-adhesives.

Embodiment 2 5

[0039] The difference from Example 1 is that the addition amount of each component of the non-bitumen pressure-sensitive self-adhesive adhesive and the addition amount of polybutene are different. The components of Examples 1 to 5 and the performance tests of the non-bitumen self-adhesive coil The results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com