Degradable composite film and preparation method thereof

A composite film and raw material technology, applied in the field of degradable composite film and its preparation, can solve the problems of natural degradation of pollution, environmental pollution, increase of plastic film, etc., achieve simple preparation process, avoid white pollution, improve strength and toughness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

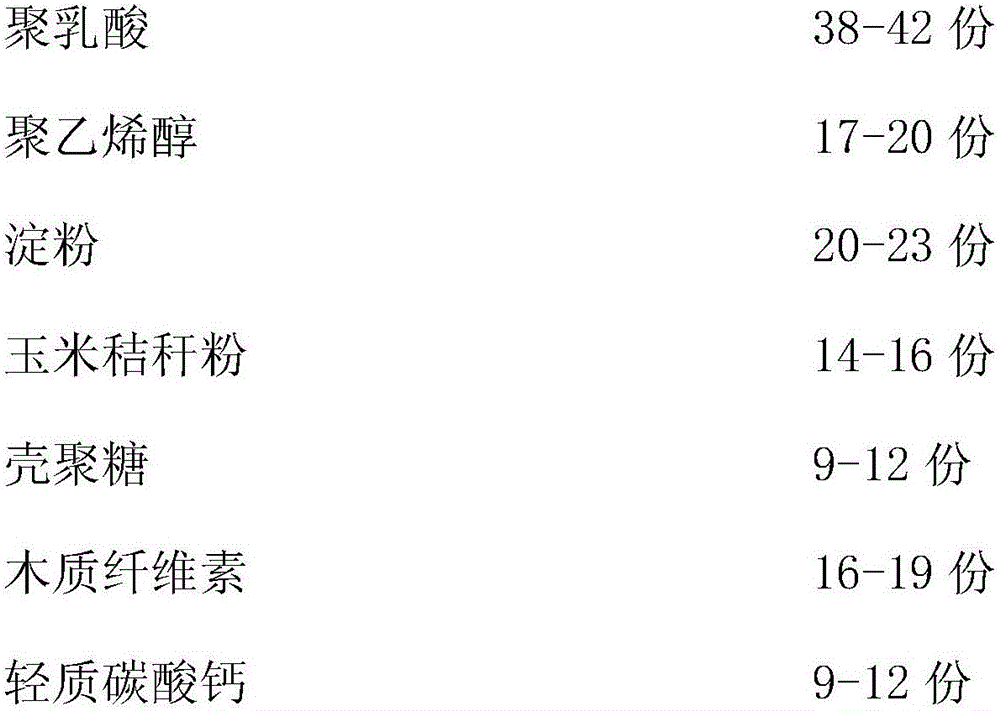

Method used

Image

Examples

Embodiment 1

[0023] A degradable composite film, which is composed of the following raw materials in parts by weight: 35 parts of polylactic acid, 15 parts of polyvinyl alcohol, 18 parts of starch, 12 parts of corn straw powder, 8 parts of chitosan, 14 parts of lignocellulose, light 7 parts of calcium carbonate, 4 parts of diatomaceous earth, 7 parts of vermiculite powder, 3 parts of zinc oxide, 2 parts of epoxy soybean oil, 0.5 part of defoamer; wherein the starch is at least one of corn starch, potato flour and sweet potato flour kind.

[0024] A preparation method of a degradable composite film, comprising the following steps:

[0025] (1) take each raw material of corresponding weight part respectively;

[0026] (2) Add polylactic acid, polyvinyl alcohol, starch, corn stalk powder, chitosan, and lignocellulose into the mixer. The heating temperature is 80°C, the rotation speed is 50r / min, and the heating time is 20min; Calcium carbonate, diatomaceous earth, vermiculite powder, zinc o...

Embodiment 2

[0030] A degradable composite film, which is composed of the following raw materials in parts by weight: 45 parts of polylactic acid, 22 parts of polyvinyl alcohol, 25 parts of starch, 17 parts of corn straw powder, 13 parts of chitosan, 20 parts of lignocellulose, light 13 parts of calcium carbonate, 9 parts of diatomaceous earth, 12 parts of vermiculite powder, 8 parts of zinc oxide, 7 parts of epoxy soybean oil, 3 parts of defoamer; wherein the starch is at least one of corn starch, potato flour and sweet potato flour kind.

[0031] A preparation method of a degradable composite film, comprising the following steps:

[0032] (1) take each raw material of corresponding weight part respectively;

[0033] (2) Add polylactic acid, polyvinyl alcohol, starch, corn stalk powder, chitosan, and lignocellulose into the mixer. The heating temperature is 90°C, the rotation speed is 60r / min, and the heating time is 30min; Calcium carbonate, diatomaceous earth, vermiculite powder, zinc...

Embodiment 3

[0037] A degradable composite film, which is composed of the following raw materials in parts by weight: 38 parts of polylactic acid, 18 parts of polyvinyl alcohol, 20 parts of starch, 14 parts of corn straw powder, 10 parts of chitosan, 16 parts of lignocellulose, light 9 parts of calcium carbonate, 6 parts of diatomite, 9 parts of vermiculite powder, 5 parts of zinc oxide, 4 parts of epoxy soybean oil, 1 part of defoamer; wherein the starch is at least one of corn starch, potato flour and sweet potato flour kind.

[0038] A preparation method of a degradable composite film, comprising the following steps:

[0039] (1) take each raw material of corresponding weight part respectively;

[0040] (2) Add polylactic acid, polyvinyl alcohol, starch, corn stalk powder, chitosan, and lignocellulose into the mixer. The heating temperature is 85°C, the rotation speed is 55r / min, and the heating time is 25min; Calcium carbonate, diatomaceous earth, vermiculite powder, zinc oxide and e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com