Method used for preparing high-purity phycoerythrin via chitosan adsorption

A phycoerythrin, high-purity technology, applied in the preparation method of peptides, chemical instruments and methods, algae/bryopeptides, etc., can solve the problems of complex operation, high production cost, dependence, etc., and achieve simple and easy operation, The effect of low cost and high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Centrifuge to collect 10 g of freshly cultivated Porphyridium algae, mix the algae mud with phosphate buffer in a ratio of 1:5 to obtain a cell suspension;

[0022] (2) The cell suspension obtained in step (1) was repeatedly frozen and thawed 5 times to obtain a wall-breaking liquid; the wall-breaking liquid was refrigerated and centrifuged at 10000r / min for 10min, and the supernatant was collected;

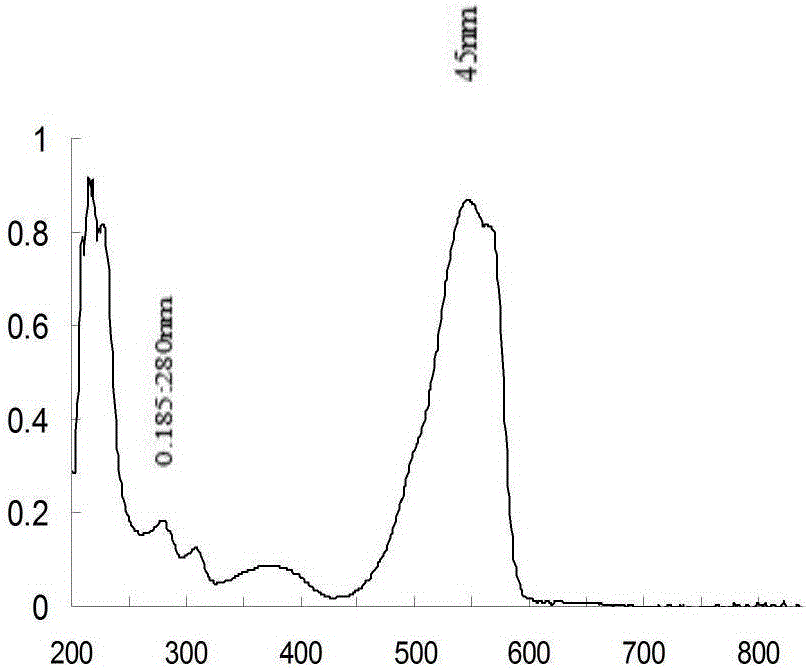

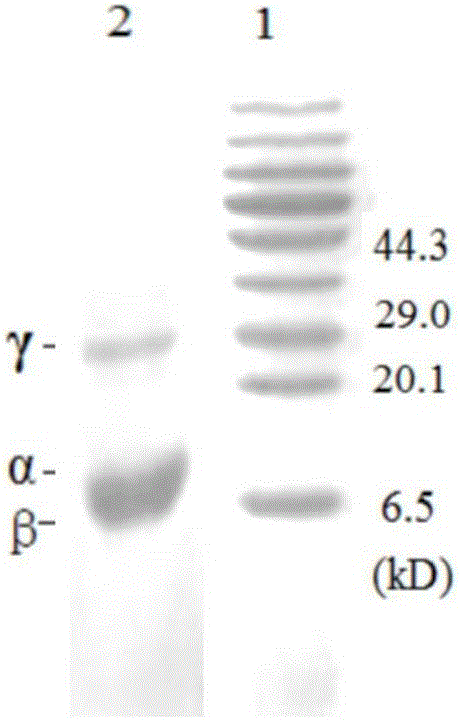

[0023] (3) Add chitosan solution dropwise to the supernatant obtained in step (2) until the mass concentration of chitosan is 0.5%, fully mix, freeze and centrifuge at 10000r / min for 10min, then take the precipitate; add Phosphate buffer solution containing 0.1mol / L sodium chloride, mix thoroughly, and centrifuge at 10,000r / min for 10min to take the precipitate; then add phosphate buffer solution containing 0.3mol / L sodium chloride to the precipitate, mix thoroughly After uniformity, freeze and centrifuge at 10000r / min for 10min, take the supernatant; take a small amou...

Embodiment 2

[0028] (1) Centrifuge to collect 30 g of freshly cultivated Porphyridium algae, mix the algae mud and phosphate buffer in a ratio of 1:8 to obtain a cell suspension;

[0029] (2) The cell suspension obtained in step (1) was repeatedly frozen and thawed 6 times to obtain a wall-breaking liquid; the wall-breaking liquid was refrigerated and centrifuged at 10000r / min for 10min, and the supernatant was collected;

[0030] (3) Chitosan solution is added dropwise to the supernatant obtained in step (2) until the chitosan mass concentration is 0.3%, fully mixed, refrigerated and centrifuged at 10000r / min for 10min, and the precipitate is taken; 0.1mol / L sodium chloride phosphate buffer solution, mix well, then freeze and centrifuge at 10000r / min for 10min, take the precipitate, then add 0.3mol / L sodium chloride phosphate buffer solution to the precipitate, mix well Afterwards, refrigerate and centrifuge at 10000r / min for 10min, and take the supernatant;

[0031] (4) At room temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com