Preparation method of polymethoxyl dimethyl ether by using lewis acid as catalyst

A polymethoxydimethyl ether and Lewis acid technology, which is applied in chemical instruments and methods, preparation of organic compounds, chemical recovery, etc., can solve the problem of high cost of ionic liquid catalysts, and achieve low follow-up processing costs and simple follow-up processing. , The effect of reducing equipment maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

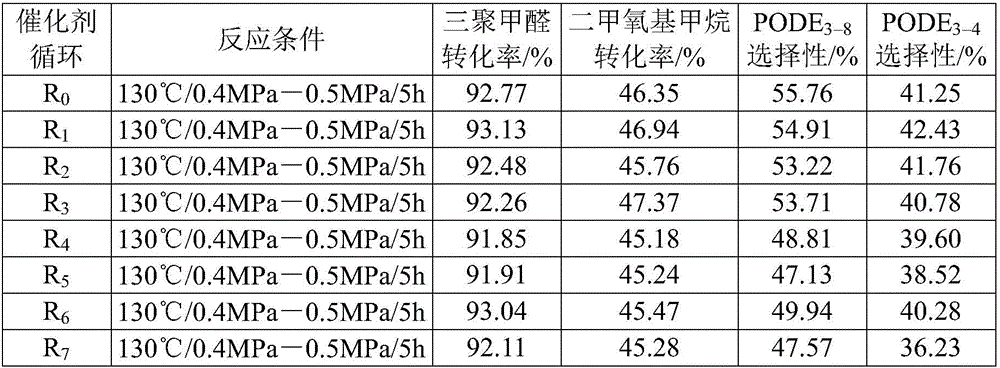

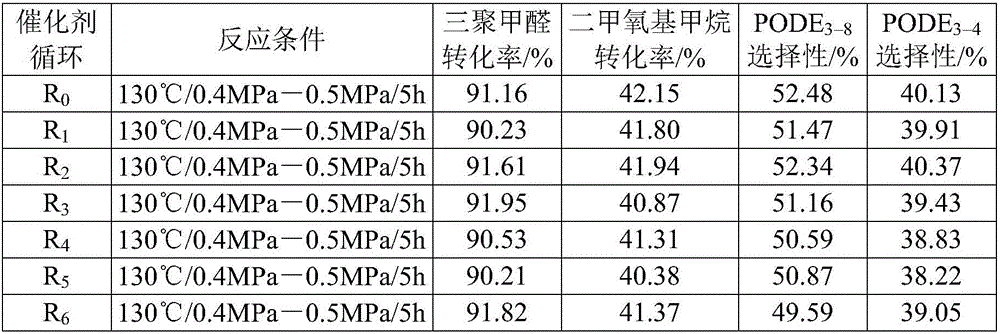

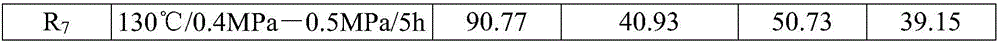

Examples

Embodiment 1

[0029] The present embodiment provides a kind of method that takes Lewis acid as catalyst to prepare polyoxymethylene dimethyl ether, and this method comprises the steps:

[0030] In a 250mL autoclave, add 0.075g Lewis acid catalyst MgCl 2 , 10.07g dimethoxymethane, 5.95g paraformaldehyde. Pressurize to 0.4MPa with nitrogen, heat to 130°C, start stirring, react for 5 hours, lower the temperature, take out the product, recover the catalyst, and obtain the reaction product, which is a mixture containing polyoxymethylene dimethyl ether and raw materials.

[0031] The obtained reaction product is determined:

[0032] The reaction product is weighed, sampled and analyzed by gas chromatography. The analysis results show that the conversion rate of paraformaldehyde is 93.89%, the conversion rate of dimethoxymethane is 46.76%, and the PODE 3-8 Selectivity is 56.28%, PODE 3-4 The selectivity is 41.11%.

[0033] This embodiment also provides polyoxymethylene dimethyl ether prepared by...

Embodiment 2

[0035] The present embodiment provides a kind of method that takes Lewis acid as catalyst to prepare polyoxymethylene dimethyl ether, and this method comprises the steps:

[0036] In a 250mL autoclave, add 0.42g Lewis acid catalyst Fe 2 (SO 4 ) 3 , 13.27g dimethoxymethane, 9.87g paraformaldehyde. Pressurize to 0.4MPa with nitrogen, adjust the temperature to 130°C, start stirring, react for 5 hours, lower the temperature, take out the product, recover the catalyst, and obtain the reaction product, which is a mixture containing polyoxymethylene dimethyl ether and raw materials .

[0037] The obtained reaction product is determined:

[0038] The reaction product is weighed, sampled and analyzed by gas chromatography. The analysis results show that the conversion rate of paraformaldehyde is 92.19%, the conversion rate of dimethoxymethane is 43.23%, and the PODE 3-8 Selectivity is 53.41%, PODE 3-4 The selectivity is 43.85%.

[0039] This embodiment also provides polyoxymethy...

Embodiment 3

[0041] The present embodiment provides a kind of method that takes Lewis acid as catalyst to prepare polyoxymethylene dimethyl ether, and this method comprises the steps:

[0042] In a 250mL autoclave, add 1.74g Lewis acid catalyst MgSO 4 , 15.21g dimethoxymethane, 17.52g paraformaldehyde. Pressurize to 0.4MPa with nitrogen, adjust the temperature to 130°C, start stirring, react for 5 hours, lower the temperature, take out the product, recover the catalyst, and obtain the reaction product, which is a mixture containing polyoxymethylene dimethyl ether and raw materials .

[0043] The obtained reaction product is determined:

[0044] The reaction product is weighed, sampled and analyzed by gas chromatography. The analysis results show that the conversion rate of paraformaldehyde is 91.87%, the conversion rate of dimethoxymethane is 45.66%, and the PODE 3-8 Selectivity is 54.91%, PODE 3-4 The selectivity is 41.76%.

[0045] This embodiment also provides polyoxymethylene dime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com