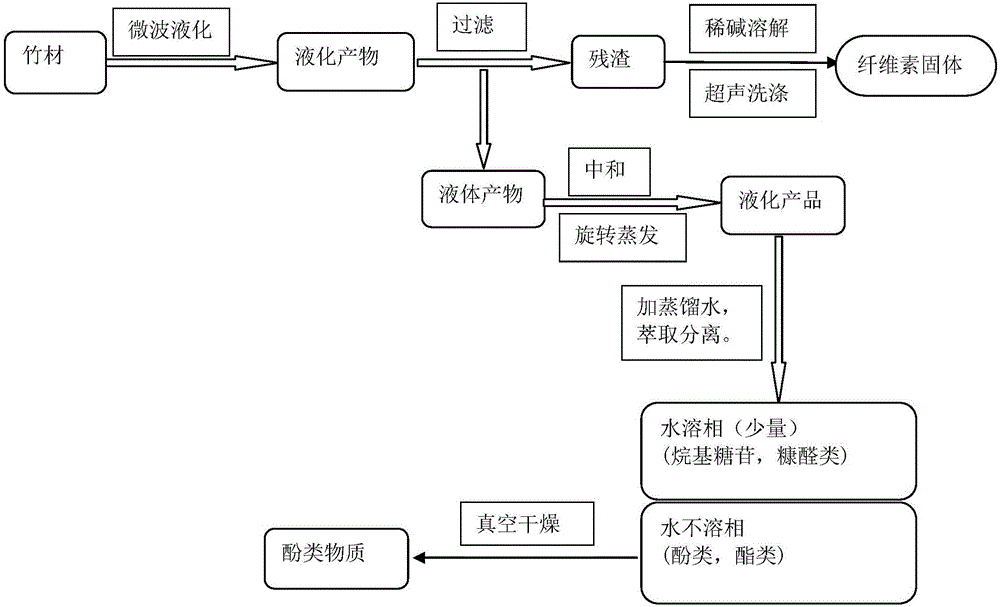

Method for directional liquefaction of woody biomass to obtain high value-added chemicals and comprehensive utilization of liquefaction residue

A liquefaction residue, high value-added technology, applied in chemical instruments and methods, organic chemistry, textiles and papermaking, etc., can solve problems such as the difficulty of rational utilization, achieve low price, simple solvent recovery operation, and improve the conversion rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Weigh 2g of absolute dry weight bamboo, add 16g of methanol and 0.05g of sulfuric acid into a polytetrafluoroethylene reactor with a volume of 100mL, seal the high-pressure reactor, and put it into a microwave reaction system. Stir. It took 5 minutes to raise the temperature to 180°C, and the temperature was raised to 180°C for 10 minutes. After the reaction was completed, the temperature in the reactor was rapidly cooled to room temperature through cooling water. Open the reaction kettle, filter the directly pressurized liquefied product to obtain residue and filtrate. The filtrate was neutralized with NaOH solution, and the liquefied low-carbon alcohol solvent was recovered by rotary evaporation. The liquid product was added to 20 g of distilled water, resulting in a water-soluble phase and a water-insoluble phase. The water-soluble phase was poured out, and 0.67 g of the water-soluble phase product was obtained after rotary evaporation of distilled water. The wat...

Embodiment 2

[0040]Weigh 2g of dry weight bamboo, add 16g of methanol and 0.1g of sulfuric acid into a polytetrafluoroethylene reaction kettle with a volume of 100mL, seal the high-pressure reaction kettle, and put it into a microwave reaction system. The microwave reaction system includes microwave reaction and constant uniform magnetic force Stir. It took 5 minutes to raise the temperature to 180°C, and the temperature was raised to 180°C for 10 minutes. After the reaction was completed, the temperature in the reactor was rapidly cooled to room temperature through cooling water. Open the reaction kettle, filter the directly pressurized liquefied product to obtain residue and filtrate. The filtrate was neutralized with NaOH solution, and the liquefied low-carbon alcohol solvent was recovered by rotary evaporation. The liquid product was added to 20 g of distilled water, resulting in a water-soluble phase and a water-insoluble phase. The water-soluble phase was poured out, and 0.71 g of...

Embodiment 3

[0042] Weigh 2g of absolute dry weight bamboo, add 16g of methanol and 0.2g of sulfuric acid into a polytetrafluoroethylene reactor with a volume of 100mL, seal the high-pressure reactor, and put it into a microwave reaction system. Stir. It took 5 minutes to raise the temperature to 180°C, and the temperature was raised to 180°C for 10 minutes. After the reaction was completed, the temperature in the reactor was rapidly cooled to room temperature through cooling water. Open the reaction kettle, filter the directly pressurized liquefied product to obtain residue and filtrate. The filtrate was neutralized with NaOH solution, and the liquefied low-carbon alcohol solvent was recovered by rotary evaporation. The liquid product was added to 20 g of distilled water, resulting in a water-soluble phase and a water-insoluble phase. The water-soluble phase was poured out, and after rotary evaporation of distilled water, 0.60 g of the water-soluble phase product was obtained. The wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com