A two-time molding method for a ceramic ball for cement grinding

A technology of overmolding and ceramic balls, which is applied in grain processing, etc., can solve problems such as poor performance and surface defects, achieve good lubrication performance, prevent formation and expansion of adhesion, and reduce life expectancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] First, put 97-99 parts of alumina micropowder, 0.1-0.5 parts of alumina whiskers, 0.4-2.5 parts of zirconia, and 0.05-0.1 parts of binder into the ball mill, add water for wet grinding, run for 30-45 hours, pass 0.063 mm sieved and put into the mud pool to stir and stale for 36-50 hours, and then remove iron to obtain a slurry with a water content of 60%, and the fineness of the slurry is D50≤1.2μm; wherein, the particle size of the alumina micropowder is 0.1- 2 μm; the zirconia is nano-particles with a particle size of 4-60 nm; the average diameter of the aluminum oxide whiskers is 0.5-2 μm, and the average length is 8-100 μm. The binding agent is La 2 o 3 , Y 2 o 3 , SiO 2 、TiO 2 , CaO, MgO, talc in any one or more of the mixture. Then, the obtained slurry is input into the spray drying tower for spray powder making, and the dried powder is transported to a large silo for 2-4 days to obtain a powder with a water content of 1.5-3%. Extrusion molding or The metho...

Embodiment 2

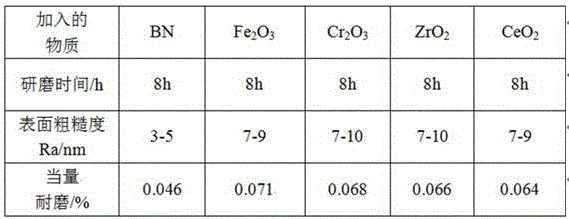

[0030] First, put 97-99 parts of alumina micropowder, 0.1-0.5 parts of alumina whiskers, 0.4-2.5 parts of zirconia, and 0.05-0.1 parts of binder into the ball mill, add water for wet grinding, run for 30-45 hours, pass 0.063 mm sieved and put into the mud pool to stir and stale for 36-50 hours, and then remove iron to obtain a slurry with a water content of 60%, and the fineness of the slurry is D50≤1.2μm; wherein, the particle size of the alumina micropowder is 0.1- 2 μm; the zirconia is nanoparticles with a particle size of 4-60 nm; the average diameter of aluminum oxide whiskers is 0.5-2 μm, and the average length is 8-100 μm; the binder is La 2 o 3 , Y 2 o 3 , SiO 2 、TiO 2 , CaO, MgO, talc, any one or more mixtures; the particle size of boron nitride is 20-200nm. Then the obtained slurry is input into the spray drying tower for spray powder making, and the dried powder is transported to the large silo to stale for 2-4 days to obtain a powder with a water content of 1....

Embodiment 3

[0036] First, put 97-99 parts of alumina micropowder, 0.1-0.5 parts of alumina whiskers, 0.4-2.5 parts of zirconia, and 0.05-0.1 parts of binder into the ball mill, add water for wet grinding, run for 30-45 hours, pass 0.063 mm sieved and put into the mud pool to stir and stale for 36-50 hours, and then remove iron to obtain a slurry with a water content of 60%, and the fineness of the slurry is D50≤1.2μm; wherein, the particle size of the alumina micropowder is 0.1- 2 μm; the zirconia is nanoparticles with a particle size of 4-60 nm; the average diameter of aluminum oxide whiskers is 0.5-2 μm, and the average length is 8-100 μm; the binder is La 2 o 3 , Y 2 o 3 , SiO 2 、TiO 2 , CaO, MgO, talc, any one or more mixtures; the particle size of boron nitride is 20-200nm. Then the obtained slurry is input into the spray drying tower for spray powder making, and the dried powder is transported to the large silo to stale for 2-4 days to obtain a powder with a water content of 1....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com