Electromagnetic vibrating feeder

A technology of electromagnetic vibration feeding and electromagnetic vibrator, which is applied in the direction of vibrating conveyors, conveyors, conveyor objects, etc., can solve the problems of affecting the accuracy of feeding and not being able to screen raw materials at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

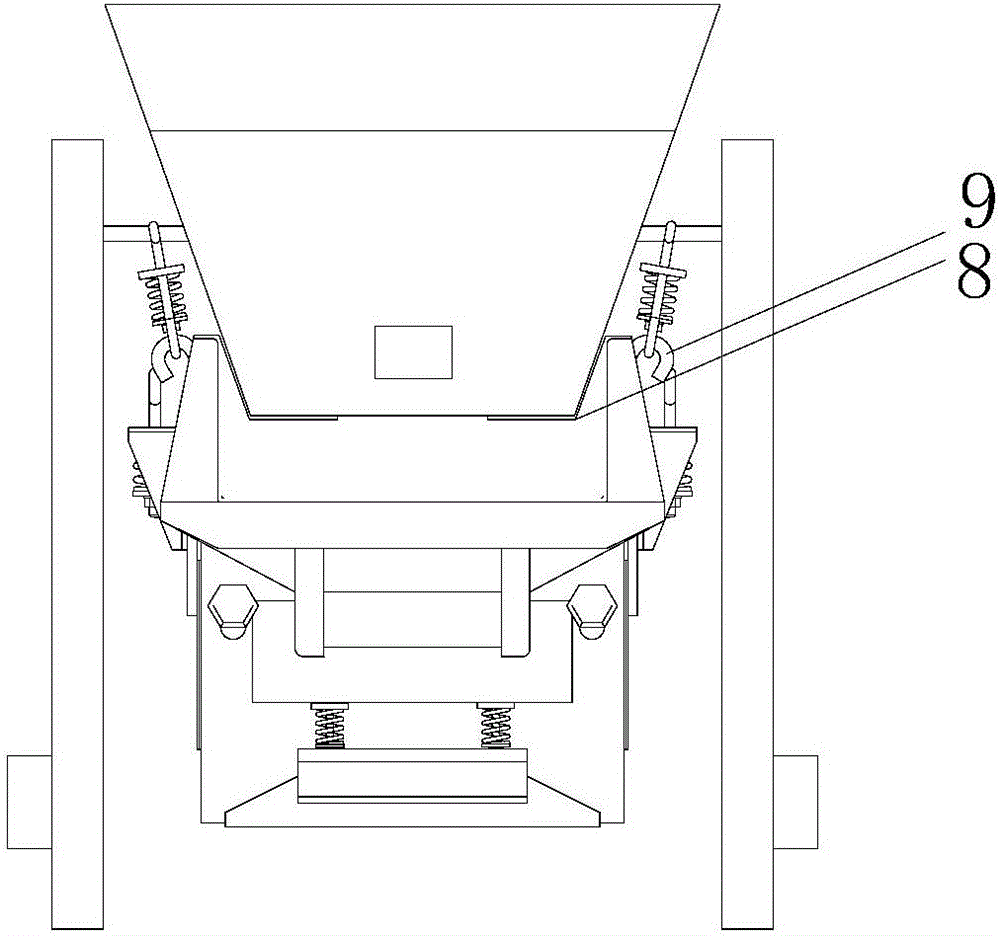

[0025] An electromagnetic vibrating feeder, such as figure 1 , figure 2 As shown, it includes an electromagnetic vibrator 1, an electromagnetic vibrator base 2, a feeder support 3, a feed hopper 4, a sieve plate 5, a shock absorber 6 and a feeding trough 7; the electromagnetic vibrator 1 is fixed on the electromagnetic vibrator through a spring connection. On the vibrator base 2, the electromagnetic vibrator 1 is connected with the feed trough 7 by bolts; the inside of the feed trough 7 is equipped with a slope support 8, and the outer wall is welded with hanging ears 9; the feed hopper 4 is placed on the slope support 8 and connected to the slope The bracket 8 is wedged together, and the bottom of the feeding hopper 4 is fixedly equipped with a sieve plate 5; the shock absorber 6 has hooks at both ends, and the hooks at both ends are respectively connected to the cross bar of the feeder bracket 3 and the hanging ear 9 of the feeding trough.

[0026] Turn on the electromagne...

Embodiment 2

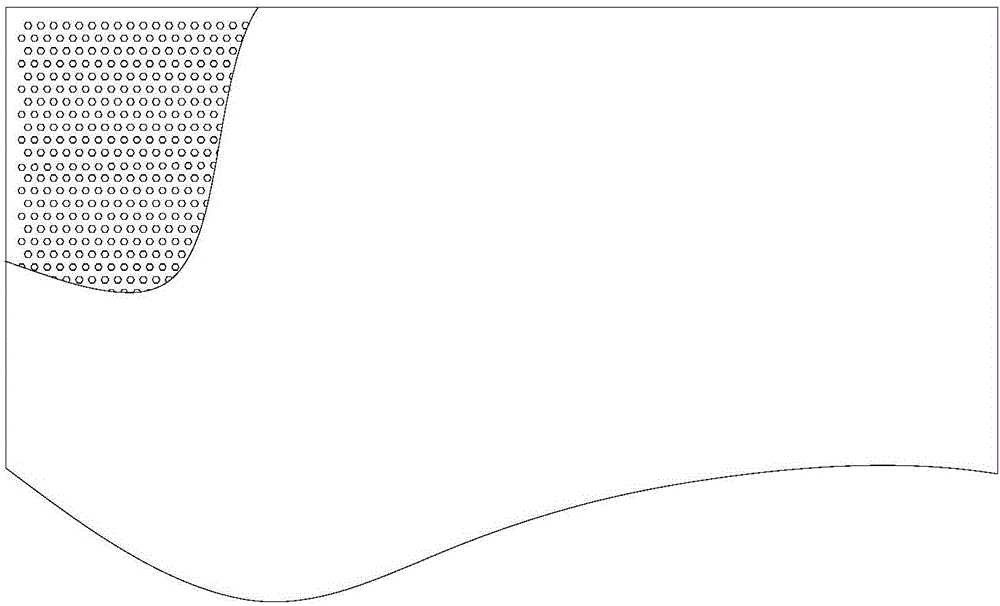

[0031] In order to further enhance the passing rate of the material through the sieve plate, the mesh of the sieve plate is processed into a regular hexagon or a circle.

Embodiment 3

[0033] In order to further strengthen the screening efficiency, the aftershock of the electromagnetic vibration feeder is utilized, and at the same time, the friction force between the feed hopper and the feed chute is reduced. The inventor also fixes rubber flexible gaskets on the inclined plane support 8 of the feed trough, and the gaskets The thickness is 1mm-3mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com