Electric vehicle vacuum booster and motor composite braking system and braking control method

A vacuum booster, electric vehicle technology, applied in electric vehicles, brake safety systems, brake transmissions, etc., can solve problems such as stalling, failure to consider, and failure of the vehicle controller to command in advance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

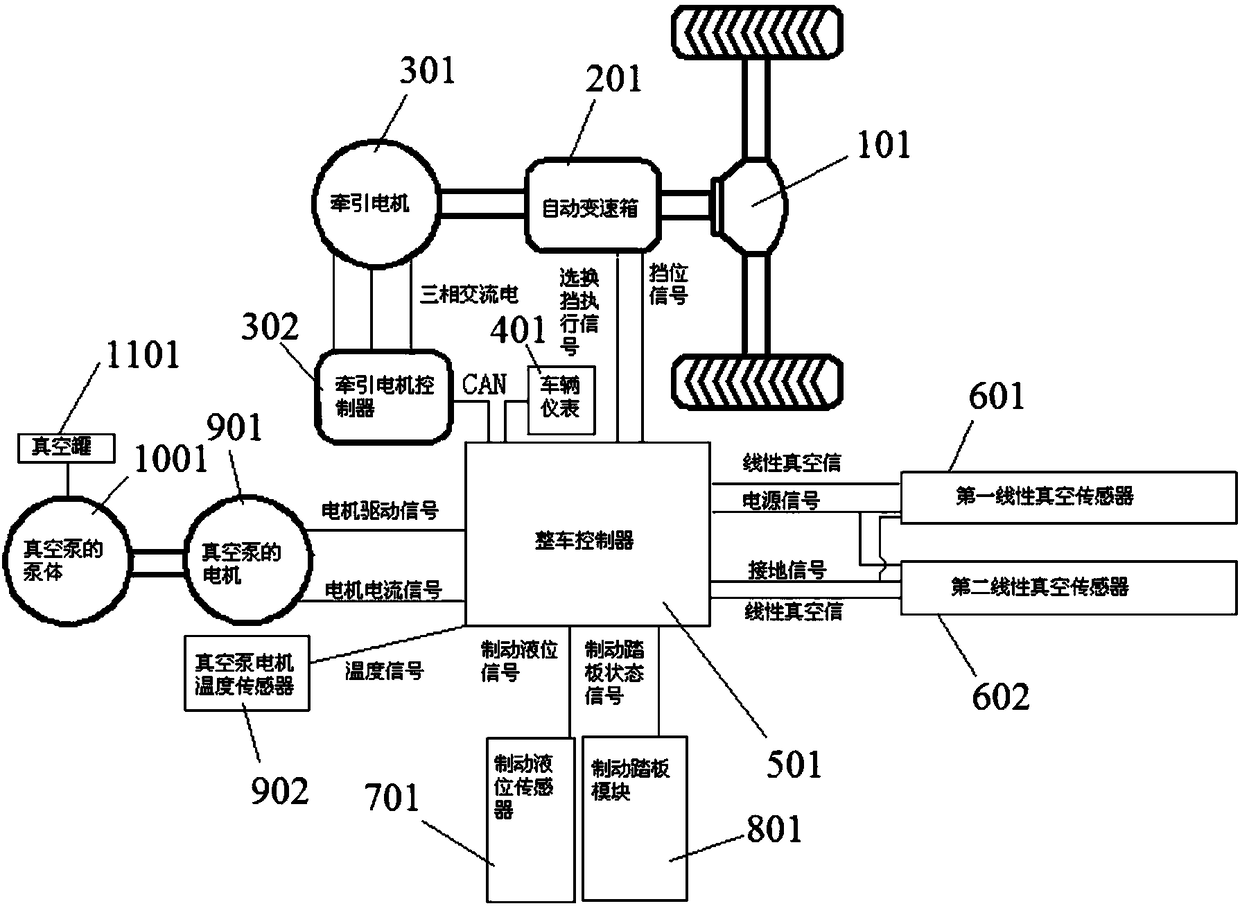

[0038] The electric vehicle vacuum booster and motor composite braking system of the present invention, such as figure 1 As mentioned above, it includes an automatic transmission 201, a traction motor 301, a traction motor controller 302, a vehicle controller 501, a vacuum pump, and a brake pedal module 801. The output shaft of the automatic transmission 201 is used to drive the vehicle drive axle 101, The output shaft of the traction motor 301 is connected to the input shaft of the automatic transmission 201, the three-phase AC output terminal of the traction motor controller 302 is connected to the three-phase AC line input terminal of the traction motor 301, and the CAN communication interface of the traction motor controller 302 is connected to the vehicle control system. The first CAN communication interface of the device 501; the gear sign...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com