Heat dissipation device and manufacturing method thereof

A technology of a heat dissipation device and a manufacturing method, which is applied in the manufacturing of semiconductor/solid state devices, electrical components, electric solid state devices, etc., can solve the problems of waste materials, poor flatness, groove tolerance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078] The above-mentioned purpose of the present invention and its structural and functional characteristics will be described according to the embodiments of the accompanying drawings.

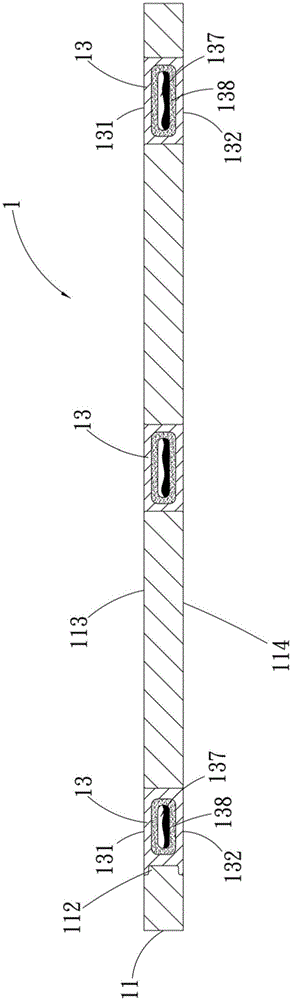

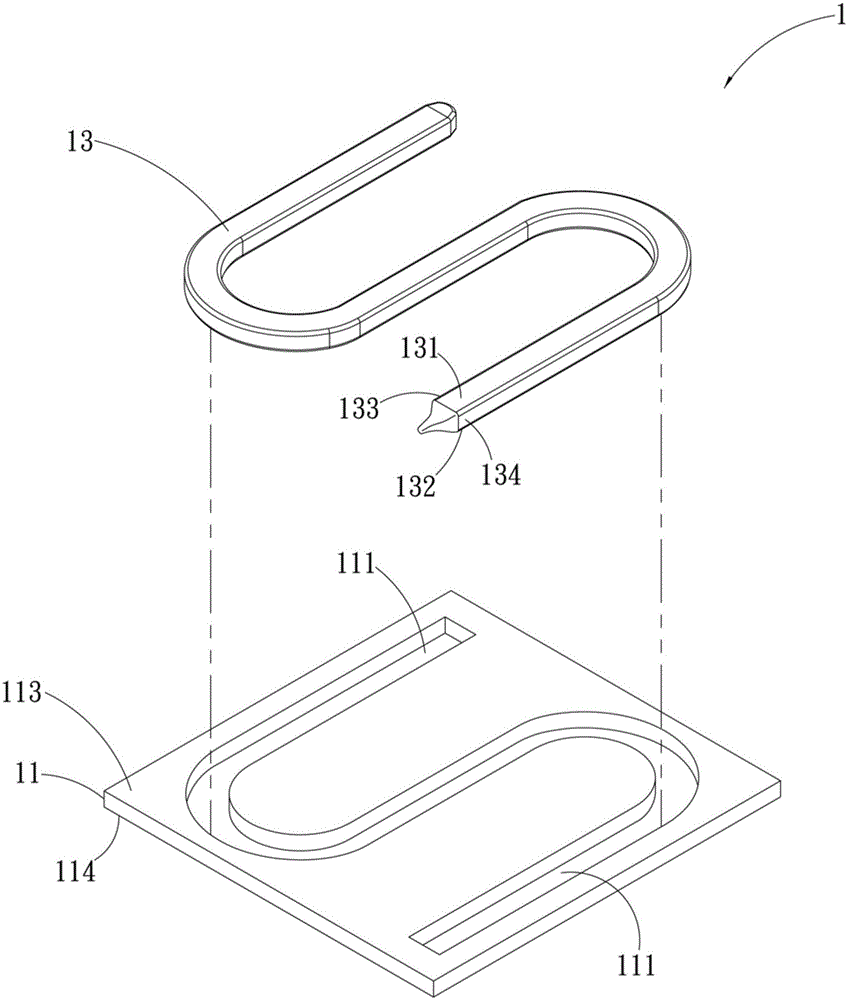

[0079] The invention provides a heat dissipation device and a manufacturing method thereof. see figure 1 , Figure 2A , Figure 2B , is the exploded and combined three-dimensional and combined cross-sectional schematic diagram of the first embodiment of the present invention. The heat dissipation device 1 includes a base plate 11 and at least one heat pipe 13, the base plate 11 is made of metal material (such as copper material), and the base plate 11 has at least one accommodating hole 111, the accommodating hole 111 is formed by the base plate 11 The top side 113 runs through the bottom side 114 opposite to the substrate 11, and the shape of the accommodating hole 111 in this preferred example is described as a zigzag shape (such as an S shape), but it is not limited thereto. , the sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com