High-temperature-resistant non-combustion cigarette paper and preparation method thereof

A non-burning cigarette, high temperature resistant technology, applied in non-woody plant/crop pulp, synthetic cellulose/non-cellulose material pulp/paper, paper, etc., can solve the problems of tar penetration, blackening of cigarette paper, deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

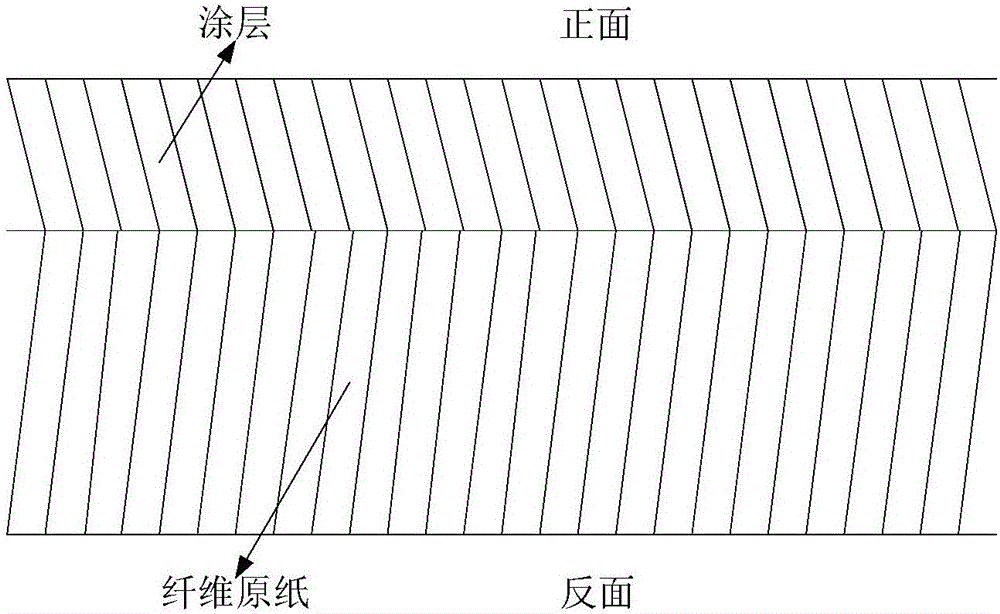

[0028] Take coniferous wood pulp with a beating degree of 28°SR and hardwood pulp with a beating degree of 40°SR, and mix them according to a mass ratio of 3:2; add filler calcium carbonate, the amount of which is 30% of the base paper; add guar gum, the amount of 1% of base paper weight. Where there is no special description, the cigarette paper is produced according to the conventional cigarette paper papermaking process. After the wire part is formed, the AKD surface sizing treatment is carried out on the cigarette paper. The solid content of AKD is 1.0%. Control index of cigarette paper on papermaking equipment: quantitative: 60g / m 2 ;Breathability: 10CU. Preparation of paint: Take silicone epoxy resin adhesive, light calcium carbonate, stearamide and water according to the mass ratio of 20:30:5:45, and mix them evenly to make a paint. The prepared coating is coated on the front side of the cigarette paper by single-sided coating, and the coating amount is 30g / m 2 , mad...

Embodiment 2

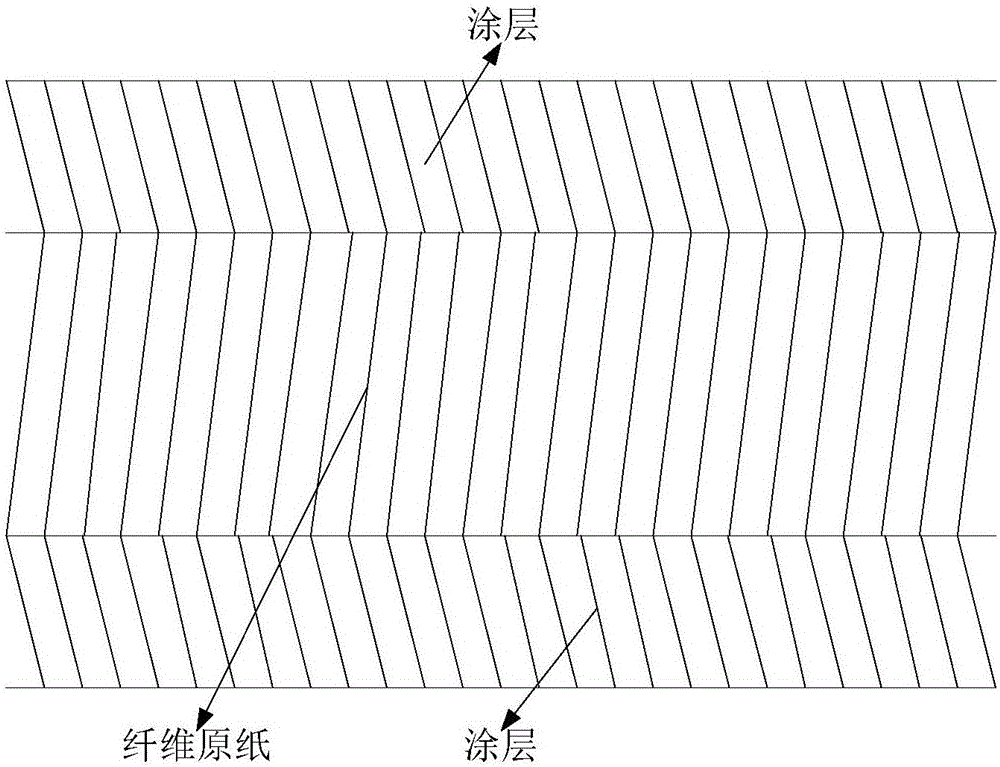

[0030] Take coniferous wood pulp beating degree is 40 ° SR, hardwood pulp beating degree is 40 ° SR, mix by mass ratio 3:2; Add filler calcium carbonate, the addition amount is 20% of base paper quantitative; Add guar gum, add The amount is 1% of the base paper; SAE surface sizing treatment is carried out on the cigarette paper, and the solid content of SAE is 1.0%. If there is no special description, cigarette paper is produced according to the conventional cigarette paper papermaking process, and the index of cigarette paper controlled on the equipment is: Quantitative: 50g / m 2 ;Breathability: 10CU. Preparation of paint: Mix silicone epoxy resin adhesive, light calcium carbonate, EBS and water at a mass ratio of 10:45:1:44, and mix evenly to make a paint. The prepared coating is coated on both sides of the cigarette paper by double-sided coating, and the coating amount of each side is 20g / m 2 , made into high-temperature resistant non-combustible cigarette paper after coat...

Embodiment 3

[0032] Take coniferous wood pulp with a beating degree of 40°SR, hardwood pulp with a beating degree of 30°SR, and aluminum silicate fibers, and mix them in a mass ratio of 1:1:1; add filler titanium dioxide, and the amount added is 20% of the base paper weight. Add guar gum in an amount of 0.5% of the base paper weight; carry out polyvinyl alcohol surface sizing treatment on the cigarette paper. Unless otherwise specified, cigarette paper is produced according to the conventional cigarette paper papermaking process, and the index of cigarette paper controlled on the equipment is: quantitative: 60g / m 2 ; Air permeability is 5CU. Preparation of paint: Mix phenolic resin adhesive, magnesium hydroxide, propylene glycol and water in a mass ratio of 15:35:3:47, and mix evenly to make a paint. The paint is coated on the top of the base paper by one-sided coating, and the coating amount is 25g / m 2 , made into high-temperature resistant non-combustible cigarette paper after coating,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Air permeability | aaaaa | aaaaa |

| Air permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com