Non-woven fabric, finishing method and application f non-woven fabric

A non-woven fabric, spunbond non-woven fabric technology, applied to non-woven fabrics, finishing methods and application fields, can solve the problems affecting the application of silver ion antibacterial agents, silver ions turning black, poor discoloration resistance, etc. Inhibition of invasion and breeding, uniform fragrance release, long fragrance retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] The nonwoven fabric of this embodiment includes a nonwoven fabric body, which is composed of a fiber structure network through heat setting, including spunbond nonwoven fabric, spunbond meltblown nonwoven fabric, hot air nonwoven fabric, thermal Rolled nonwoven fabric or chemically bonded nonwoven fabric, the structural characteristics of the nonwoven fabric body in this embodiment are as follows:

[0054] 1) The upper surface layer and the lower surface layer of the nonwoven fabric body are respectively coated with a natural antibacterial and deodorant finishing agent coating.

[0055] 2) The outer layer of fibers located in the fiber structure network is covered with a natural antibacterial and deodorant finishing coating, and the gap between fibers is filled with a natural antibacterial and deodorant finishing composition.

[0056] 3) In terms of weight percentage, the weight ratio of the natural antibacterial and deodorant finishing agent to the nonwoven fabric body...

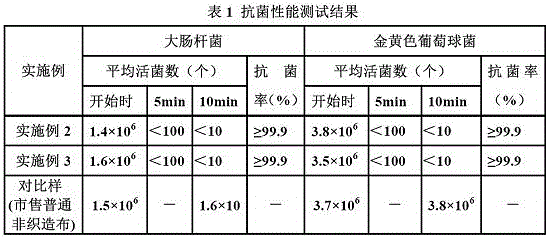

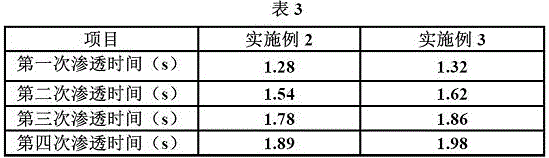

Embodiment 2

[0059] In this embodiment, the finishing of nonwoven fabrics includes the preparation process of natural antibacterial and deodorant finishing agents and the finishing process of nonwoven fabrics. The specific process and steps are as follows:

[0060] (1) Preparation of natural antibacterial and deodorant finishing agent

[0061] 1) Preparation:

[0062] Ingredients of natural antibacterial deodorant composition: chitosan 2kg; aloe vera oil 6 kg; chitin 2.5 kg; catechin 3 kg; tea polyphenol 9 kg; tea seed oil 5 kg; tea saponin 0.4 kg; grape seed Extract 4.5 kg; citric acid 6 kg; amino acid chelate 6 kg; amino acid derivatives 2.5 kg; emulsifier 2 kg, deionized water 100 kg.

[0063] Ingredients of natural antibacterial deodorant finishing agent: polyoxyethylene sorbitan tristearate 10 kg; macrogol glyceryl ether 6 kg; ester quaternary ammonium salt 5 kg; natural antibacterial composition 10 kg; fragrance slow release Body 6 kg; deionized water 63 kg.

[0064] Nonwoven fabr...

Embodiment 3

[0078] In the present embodiment, the finishing of nonwovens contains the ingredients of natural antibacterial and deodorant finishing agent as follows:

[0079] Ingredients of natural antibacterial deodorant composition: chitosan 2kg; aloe vera oil 6 kg; chitin 2.5 kg; catechin 3 kg; tea polyphenol 9 kg; tea seed oil 5 kg; tea saponin 0.4 kg; grape seed Extract 4.5 kg; citric acid 6 kg; amino acid chelate 6 kg; amino acid derivatives 2.5 kg; emulsifier 2 kg, deionized water 100 kg.

[0080] Ingredients of natural antibacterial deodorant finishing agent: polyoxyethylene sorbitan tristearate 15kg; macrogol glyceryl ether 8 kg; ester quaternary ammonium salt 7 kg; natural antibacterial deodorant composition 15kg; fragrance sustained release 4 kg body, 51 kg deionized water.

[0081] Non-woven fabric: Polypropylene hot-air non-woven fabric, the square gram weight is 16g / m 2 .

[0082] According to the process and steps of Example 2, a nonwoven fabric containing a natural antib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com