Flow fluorescent micro-sphere standard substance and method for preparing same

A flow fluorescence and standard substance technology, which is applied in the field of preparation of fluorescent microsphere standard substances, can solve the problems of demanding use, storage and transportation, complex preparation process, poor stability, etc., achieve excellent stability and increase specific surface area , the effect of uniform fluorescence intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A method for preparing a flow fluorescent microsphere standard substance, comprising the following steps:

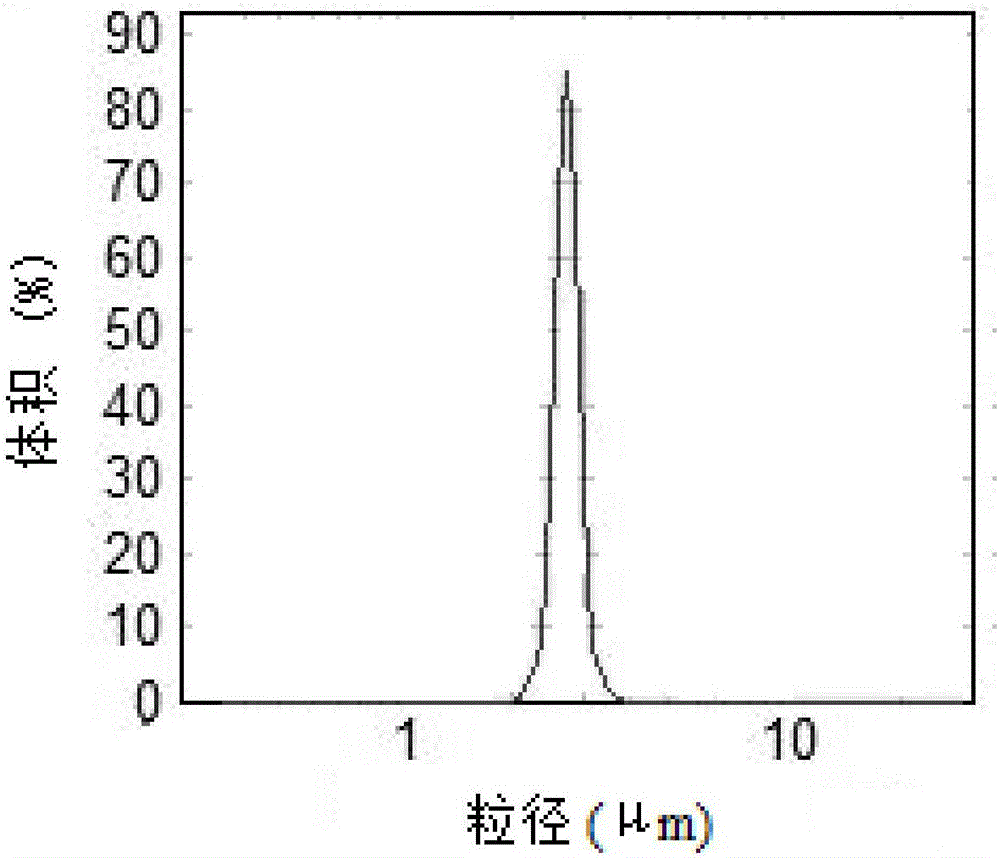

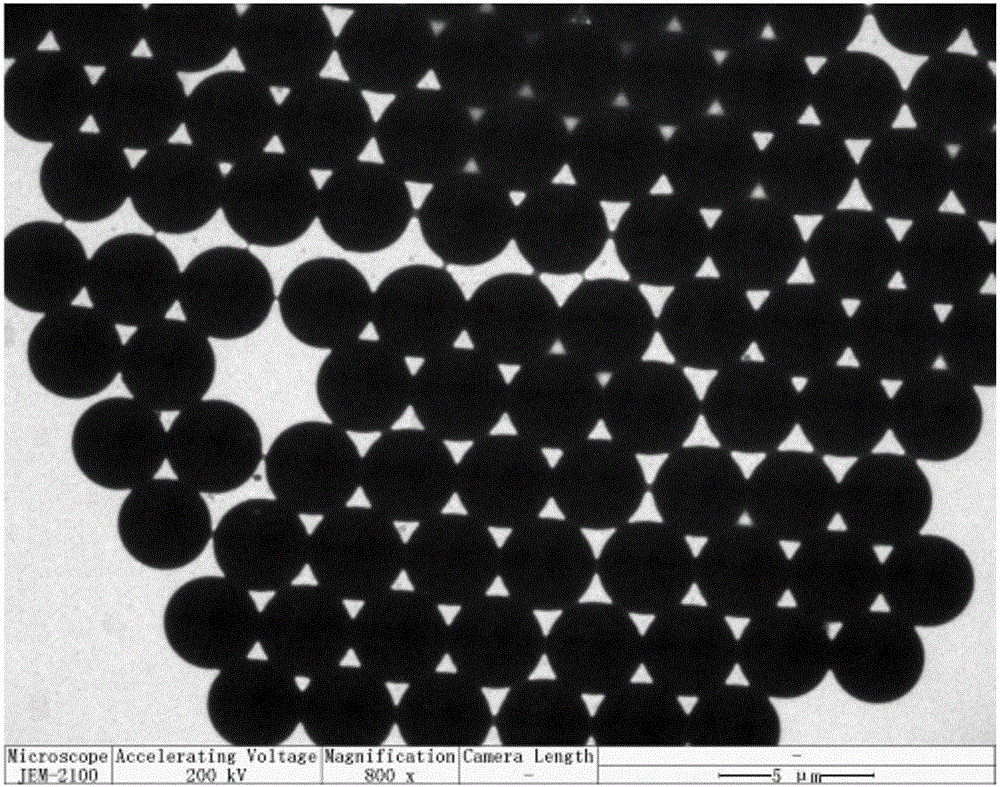

[0036] (1) Add 2.2g of polyvinylpyrrolidone, 140mL of ethanol, and 9mL of deionized water into a three-necked flask, add 55g of styrene dissolved in 0.76g of azobisisobutyronitrile and 0.07g of divinylbenzene at one time, stir and dissolve evenly ; Under the protection of nitrogen gas, the temperature was raised to 69° C., and the reaction was carried out for 22 hours; after centrifugal washing and drying, the seed microspheres were obtained, with a particle size of 3.18 μm and a coefficient of variation of 2.14%.

[0037] (2) Weigh 0.4 g of seed microspheres and add them to 100 mL of SDS aqueous solution (0.25% by mass fraction), ultrasonically disperse them to disperse the seed microspheres evenly; dissolve 1.0 mg of ethyl perylene tetracarboxylate in 5 mL of dichloromethane , added to the dispersion system of seed microspheres; after emulsification, shaking, ro...

Embodiment 2

[0040] A method for preparing a flow fluorescent microsphere standard substance, comprising the following steps:

[0041] (1) Add 2.0g of polyvinylpyrrolidone, 120mL of ethanol, and 7mL of deionized water into a three-necked flask, add 50g of styrene dissolved in 0.53g of azobisisobutyronitrile and 0.1g of divinylbenzene at one time, stir and dissolve evenly ; Under the protection of nitrogen gas, the temperature was raised to 70° C., and the reaction was carried out for 20 hours; after centrifugal washing and drying, the seed microspheres were obtained, the particle size was 3.02 μm, and the coefficient of variation was 1.78 / %.

[0042] (2) Weigh 0.5 g of seed microspheres and add them to 50 mL of SDS aqueous solution (0.25% by mass fraction), ultrasonically disperse them to disperse the seed microspheres evenly; dissolve 0.2 mg of diisobutyl perylenedicarboxylate in 5 mL of dichloromethane , added to the dispersion system of seed microspheres; after emulsification, shaking, ro...

Embodiment 3

[0045] A method for preparing a flow fluorescent microsphere standard substance, comprising the following steps:

[0046] (1) Add 1.8g of polyvinylpyrrolidone, 98mL of ethanol, and 5mL of deionized water into a three-necked flask, add 44g of styrene dissolved in 0.41g of azobisisobutyronitrile and 0.05g of divinylbenzene at one time, stir and dissolve evenly ; Under the protection of nitrogen gas, the temperature was raised to 67° C., and the reaction was carried out for 24 hours; after centrifugal washing and drying, the seed microspheres were obtained, the particle size was 3.36 μm, and the coefficient of variation was 3.32%.

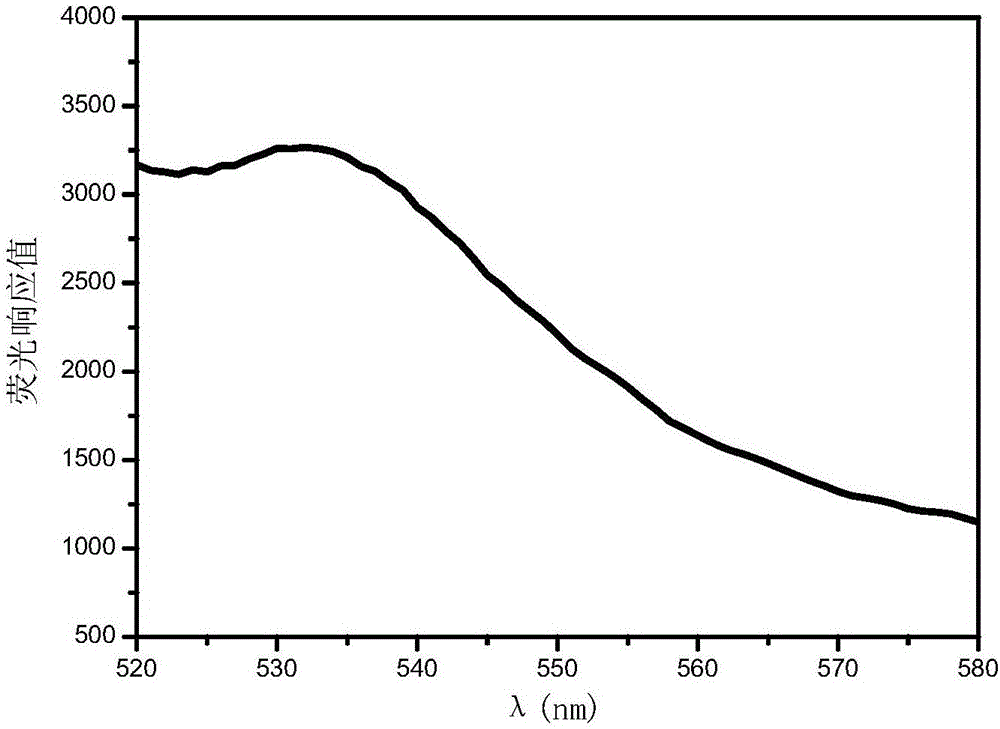

[0047] (2) Weigh 1.0 g of seed microspheres and add them to 100 mL of SDS aqueous solution (mass fraction is 0.25%), and ultrasonically disperse them to disperse the seed microspheres evenly; dissolve 5 mg of coumarin 6 in 10 mL of dichloromethane, and add to A dispersion system of seed microspheres; after emulsification, shaking, rotary evaporation, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| emission peak | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com