Hollow composite material paving slab

A technology of composite materials and paving slabs, which is applied in the field of composite material boards and preparation technology, can solve the problems of vehicle traffic, inconvenient engineering construction, inconvenient transportation and construction, and low efficiency of construction and installation, and achieve improved processing technology and improved manufacturability , Guarantee the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

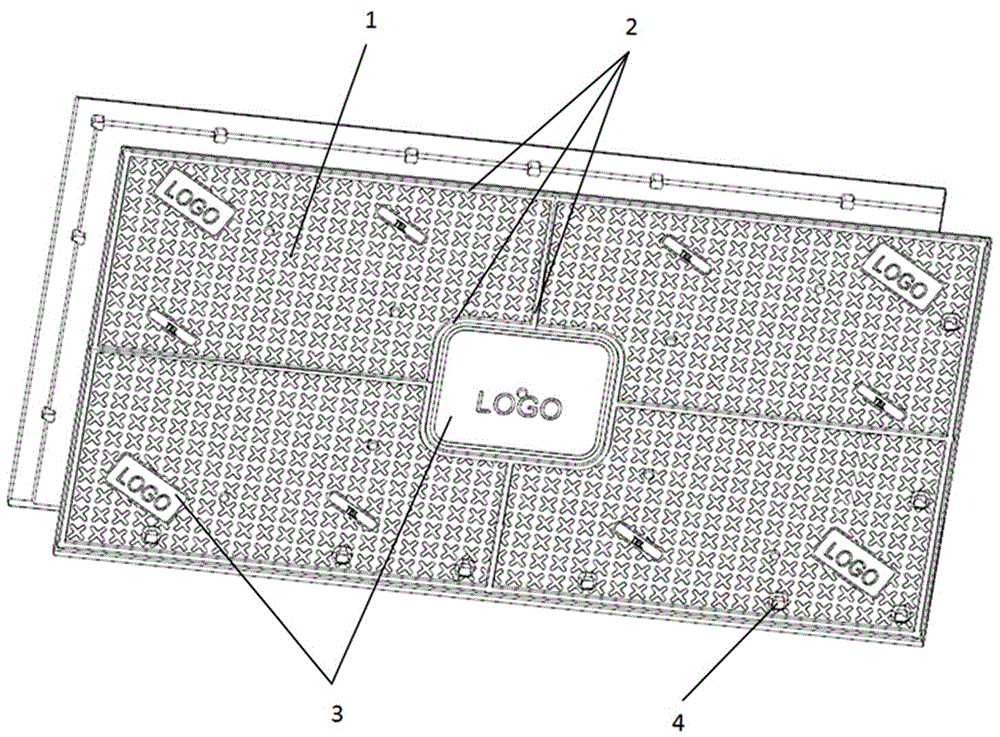

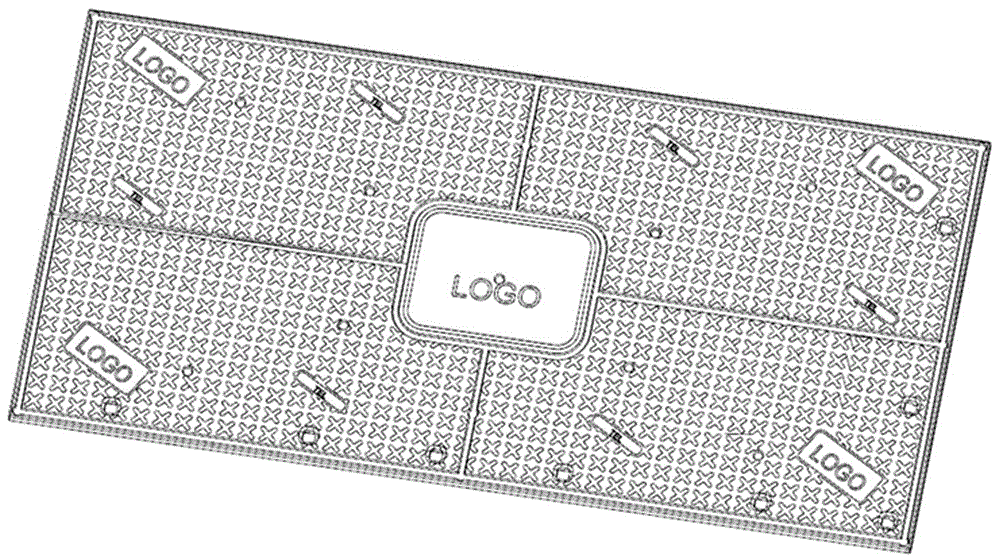

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

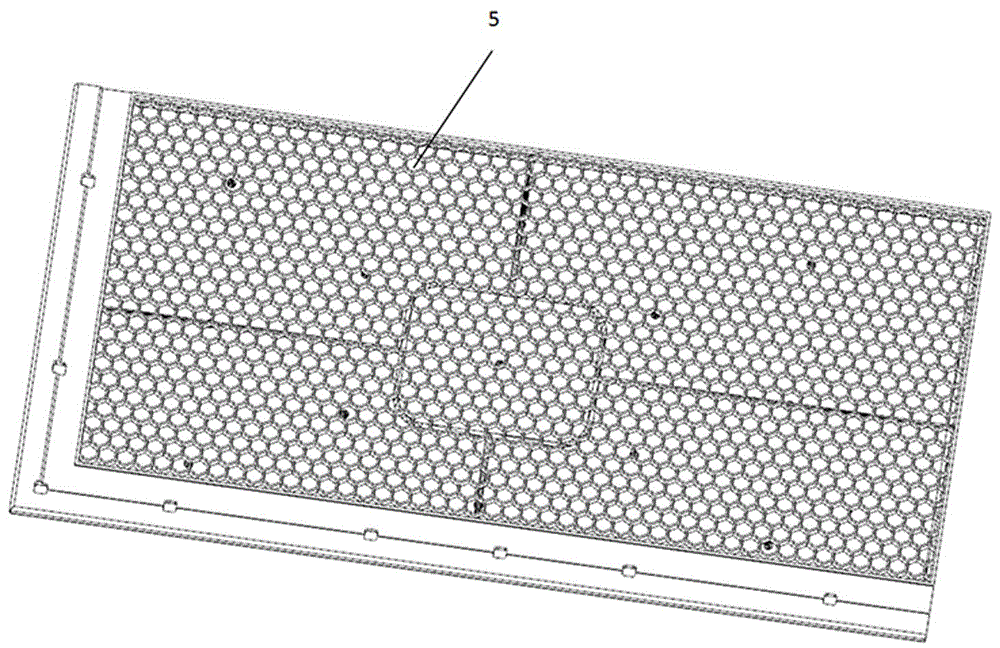

[0027] A hollow composite paving slab, made of thermoplastic material by molding process, the surface is designed with anti-skid structure 1, oil accumulation groove 2 and logo, the surrounding of the paving slab is an L-shaped structure, adjacent to both sides It is an upper L-shaped structure, and the other two sides are a lower L-shaped structure. There are pin holes 4 on the L-shaped structure. The upper L-shaped structure and the lower L-shaped structure are matched, and the pin holes 4 are compatible; Rib structure 5; paving slabs are firmly connected by connecting components 7.

[0028] The connecting assembly 7 is a cylindrical I-shaped self-locking pin.

[0029] The connecting assembly 7 is composed of a locking piece 10 and a positioning piece 11, and the positioning piece 11 and the locking piece 10 are matched through a dovetail platform and a dovetail gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com