A kind of preparation method of chelating agent

A chelating agent and reactor technology, which is applied in the field of chelating agent preparation, can solve the problems of high temperature resistance, etc., and achieve the effects of strong chelating force, good flocculation and sedimentation effect, and good temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A kind of preparation method of chelating agent, each raw material is measured in mass parts, comprises the following steps:

[0021] a. Dissolve 12 parts of maleimide in 35 parts of deionized water and 0.2 part of sodium persulfate in 25 parts of deionized water to form a solution for later use;

[0022] b. Put 24 parts of maleic anhydride and 126 parts of deionized water into the reactor, stir, dissolve, and heat up to 72°C;

[0023] c. Within 2 hours, drop maleimide, sodium persulfate aqueous solution, and 18 parts of acrylic acid into the reactor of step b, and then keep the reaction at 78° C. for 1 hour after the dropwise addition;

[0024] d. The temperature of the reactor is lowered to 30°C, firstly add 5 parts of sodium hydroxide, after dissolving, then add 10 parts of carbon disulfide, react for 3 hours, and filter to obtain the chelating agent. The degree of polymerization was 700.

Embodiment 2-4

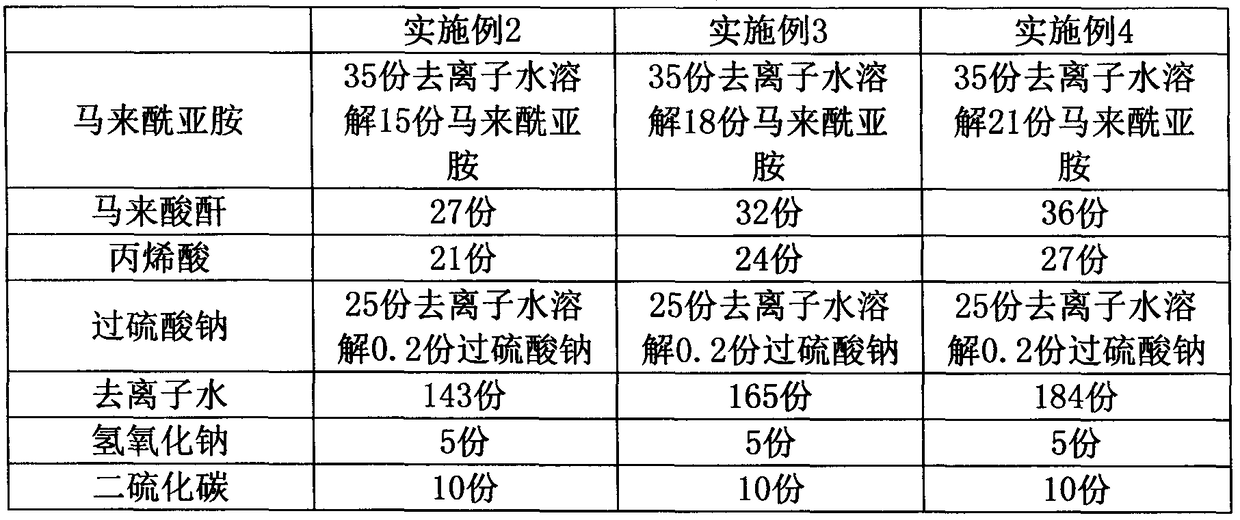

[0026] Adopt the same preparation steps and process as in Example 1, only change the input amount of raw materials such as maleimide, maleic anhydride, acrylic acid, the proportioning ratio of each raw material is as follows in Table 1, the degree of polymerization of Examples 2-4 600, 800, 700 respectively.

[0027] Table 1 Ratio of each raw material

[0028]

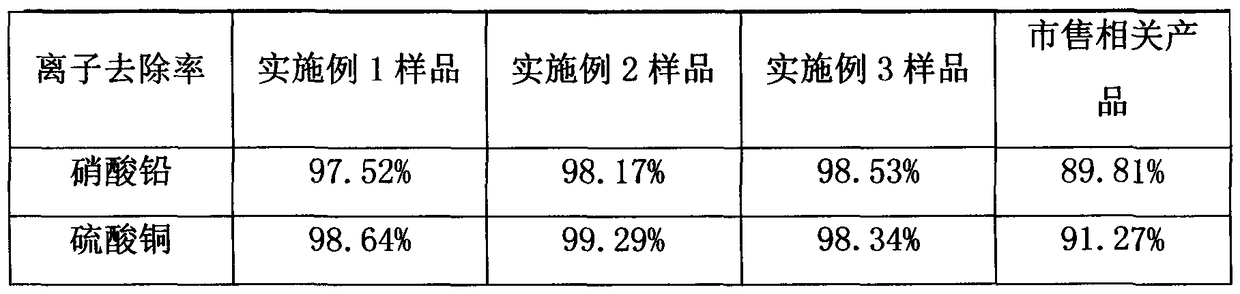

[0029] Weigh an appropriate amount of lead nitrate and copper sulfate respectively, and configure 4000mL of solutions with a concentration of 100mg / L with purified water. For related products, stir at 200 rpm for 3 minutes, stir at 100 rpm for 5 minutes, let stand for 20 minutes, take the supernatant to detect the concentration of residual metal ions C 1 , then metal ion removal rate = (C 0 -C 1 ) / C 0 *100%, C 0 = 100 mg / L.

[0030] Table 2 Chelating agent sample removes the effect of metal ion

[0031]

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com