Preparation method of ZrB2-SiC composite ceramic

A technology of composite ceramics and zrb2-sic, which is applied in the field of preparing ZrB2-SiC composite ceramics by high-temperature vacuum sintering method, can solve the problems of easy oxidation and brittleness, catastrophic damage of components, difficult sintering, etc., and achieves easy preparation, high product rate, The effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

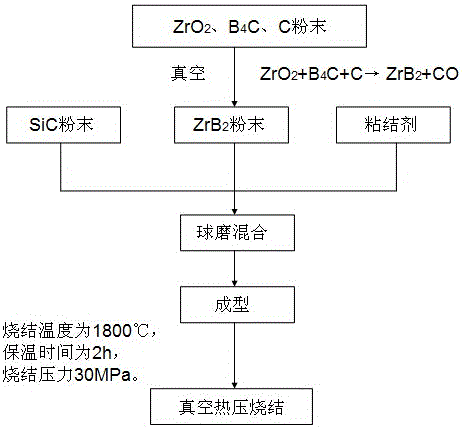

[0031] Such as figure 1 As shown, the present embodiment prepares ZrB according to the following steps 2 -SiC composite ceramics:

[0032] (1) Mixing: commercially available ZrO 2 , B 4 C and C powder are used as raw materials. The particle sizes of these three materials are all less than 10µm and the particle sizes of the three are different. ZrO 2 , B 4 The molar ratio of C and C powder is 2:1:3. After weighing, pour them into the ball mill jar, use ZrO 2 Carry out ball milling and mixing for 8 hours to achieve the effect of uniform mixing. The mixed powder is heat-treated in a vacuum furnace, put the mixed powder into an alumina ceramic cup, put it into a vacuum sintering furnace, and heat it to 1600°C for 1 hour for calcination to obtain ZrB 2 Powder.

[0033] The reaction equation is as follows:

[0034] 2ZrO 2 +B 4 C+3C→2ZrB 2 +4CO (1)

[0035] Using the above ZrO 2 -B 4 ZrB synthesized by C-C system 2 With SiC powder as the raw material, the particle size ...

Embodiment 2

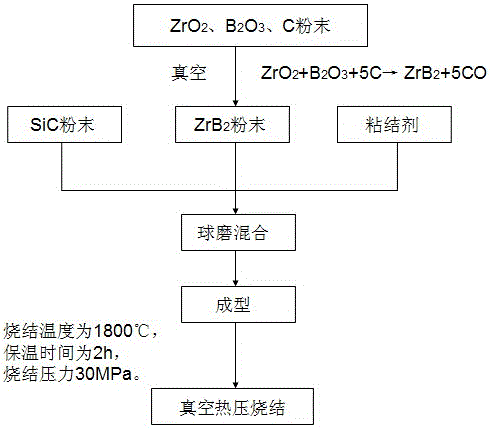

[0042] Such as figure 2 As shown, the present embodiment prepares ZrB according to the following steps 2 -SiC composite ceramics:

[0043] (1) Mixture:

[0044] Using commercially available ZrO 2 , B 2 o 3 , C powder as raw materials, the particle size of these three raw materials is less than 10µm and the particle size of the three is different, ZrO 2 , B 2 o 3 , The molar ratio of C powder is 1:1.10:5.00. After weighing, pour them into the ball mill jar, use ZrO 2 Carry out ball milling and mixing for 8 hours to achieve the effect of uniform mixing.

[0045] The mixed powder is heat-treated in a vacuum furnace, put the mixed powder into an alumina ceramic cup, put it into a vacuum sintering furnace, and heat it to 1600°C for 1 hour for calcination to obtain ZrB 2 Powder.

[0046] The reaction equation is as follows:

[0047] ZrO 2 +B 2 o 3 +5C→ ZrB 2 +5CO (2)

[0048] Using the above ZrO 2 -B 2 o 3 ZrB synthesized by -C system 2 With SiC powder as the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com