A kind of electrolyte additive and its use in lithium ion battery

A lithium-ion battery and electrolyte technology, applied in the field of lithium-ion batteries, can solve problems such as fast capacity decay, system instability, and increased battery impedance, and achieve the effects of reduced losses, suppressed by-products, and high oxidation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

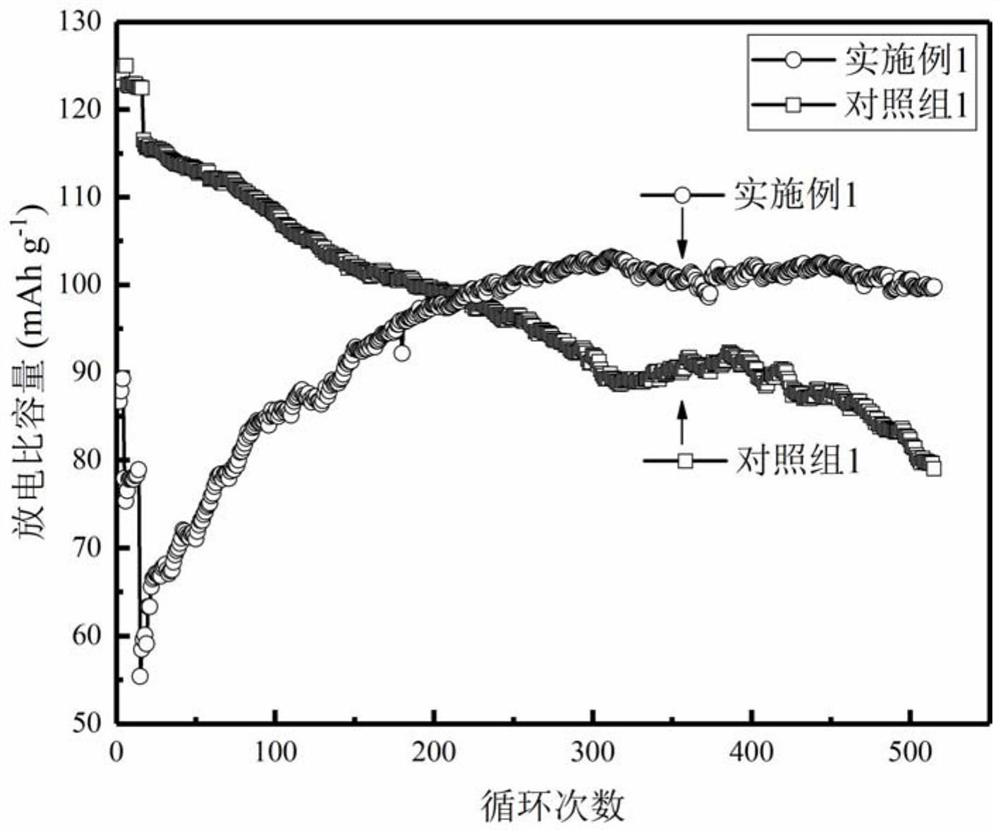

Embodiment 1

[0038] This example mainly illustrates the preparation of batteries and the preparation of electrolytes containing additives.

[0039] 1. Electrode Preparation

[0040] The mass ratio of the solid matter on the electrode is respectively active material: acetylene black: polyvinylidene fluoride (PVDF) = 8:1:1. The preparation process is as follows: first dissolve PVDF in 20-30 times the mass of N-methylpyrrolidone (NMP) to form a transparent solution, then mix and grind the active material and acetylene black, add it to the transparent solution, and stir for 8-24 hours to obtain a slurry material. The slurry was uniformly coated on the aluminum foil with a 100 μm doctor blade, heated in an oven at 80°C for 1 hour to dry, and rolled to a suitable compaction density using a pair of rollers. Heated at 100°C for 10 hours under vacuum and dried, punched into pole pieces with a diameter of 14mm, weighed, and finally heated at 120°C for 10 hours under vacuum and dried again, and dir...

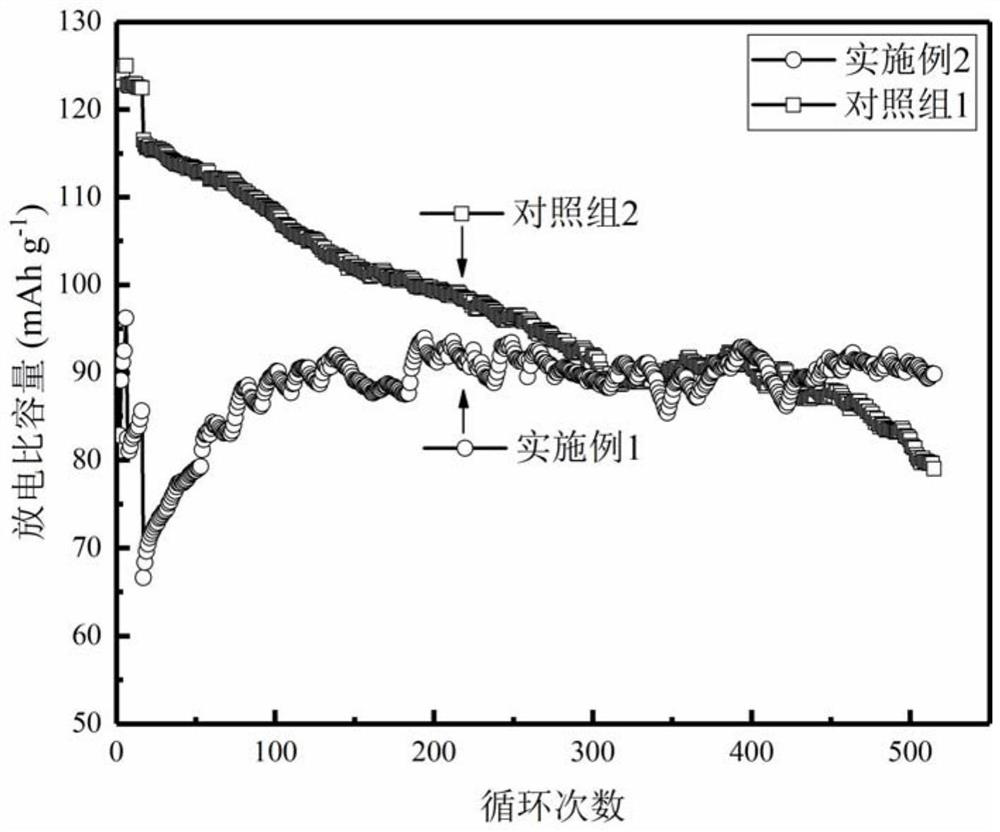

Embodiment 2

[0048] Electrolyte and lithium-ion battery are prepared according to the same method as in Example 1, except that an electrolyte additive with a mass percentage content of 0.5% is added to the electrolyte, and the obtained electrolyte is numbered as T 2 .

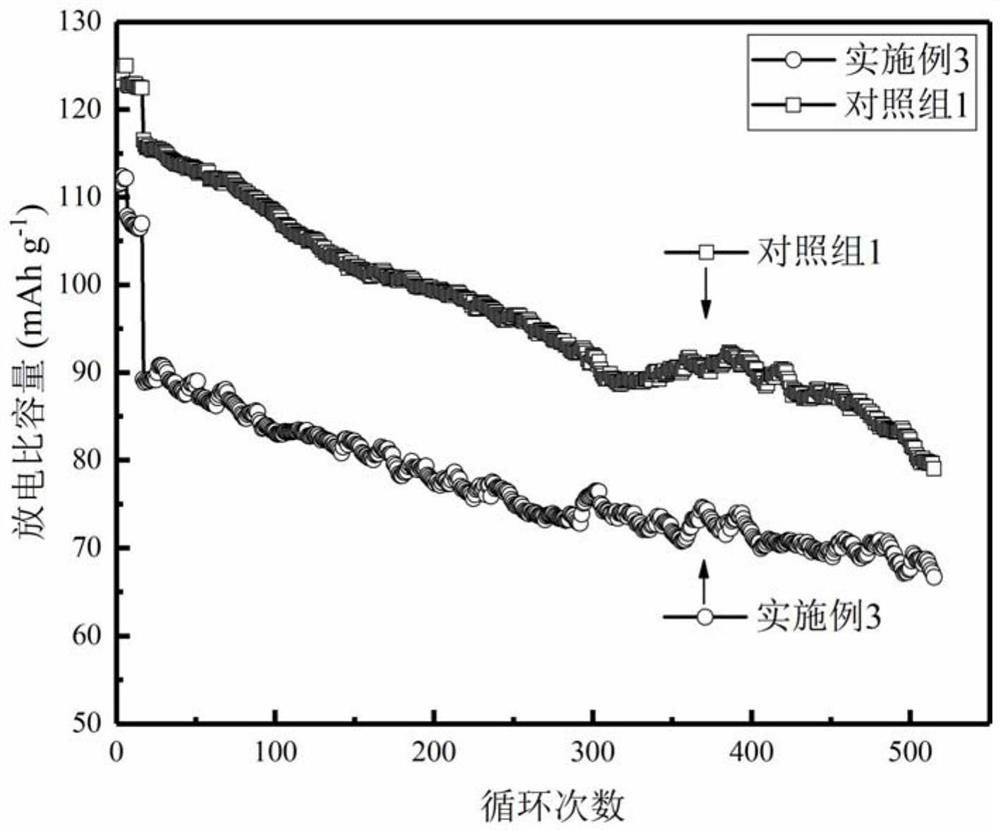

Embodiment 3

[0050] Electrolyte and lithium ion battery are prepared according to the same method as in Example 1, except that an electrolyte additive with a mass percentage content of 0.1% is added to the electrolyte, and the obtained electrolyte is numbered as T 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com