Embedded oil-water separator

An oil-water separator and embedded technology, applied in the direction of liquid separation, separation method, adsorption water/sewage treatment, etc., can solve the problems of unsatisfactory treatment results, high price of filter membrane, huge biological treatment system, etc., and achieve treatment The effect is excellent, the process is simple, and the application prospect is broad

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

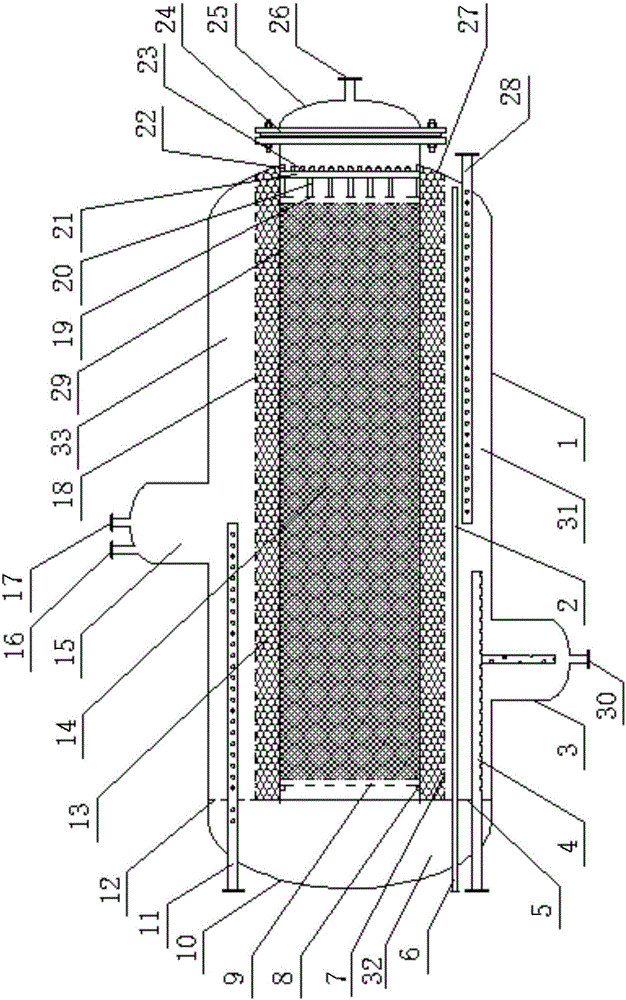

[0058] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0059] Such as figure 1 As shown, the embedded oil-water separator of the present invention includes:

[0060] Cylinder 1, the left end is provided with the left end cap 10, and the right end is provided with the right end cap 27;

[0061] At the left end of the inner cavity of the cylinder body 1, a grid plate 12 and an annular baffle plate 5 are sequentially arranged in the vertical direction from top to bottom;

[0062] The inner cylinder body 29 is inserted into the cylinder body 1 from the right end head 27, preferably centered and inserted into the cylinder body 1 from the right end head 27,

[0063] The left end of the inner cylinder 29 is connected and fixed with the annular baffle 5, and the diameter of the inner hole of the annular baffle 5 is adapted to the diameter of the inner cylinder 29,

[0064] The right end of the inner cylinder body 29 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com