Nitrogen-rich porous carbon material derived from metal-organic framework and preparation method of nitrogen-rich porous carbon material derived from metal-organic framework

A metal-organic framework and porous carbon material technology, which can be used in the preparation/purification of carbon, and can solve problems such as single

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The preparation of embodiment 1, ZIF-8 (40nm)

[0032] 50ml is dissolved with 2.47mmol zinc nitrate hexahydrate (Zn(NO 3 ) 2 ·6H 2 (2) methanol solution mixed with 50ml and 19.85mmol 2-methylimidazole (2-mIm) methanol solution, stirred at room temperature for 1 hour, centrifuged the white solid at the bottom of the solution, and dried at 60°C to obtain a particle size of 40nm ZIF-8.

Embodiment 2

[0033] The preparation of embodiment 2, ZIF-8 (80nm)

[0034] 50ml dissolved with 3.6mmol Zn(NO 3 ) 2 ·6H 2 The methanol solution of O was mixed with 50ml of methanol solution dissolved in 28.71mmol 2-mIm, stirred at room temperature for 24 hours, the white solid at the bottom of the solution was separated by centrifugation, and dried at 60°C to obtain ZIF-8 with a particle size of 80nm.

Embodiment 3

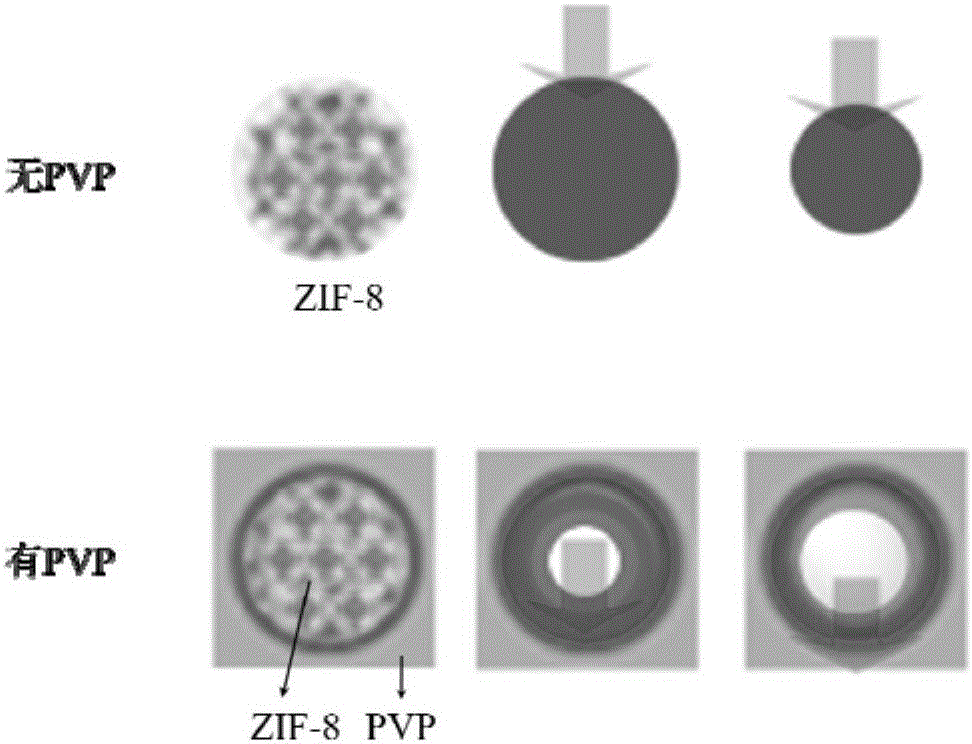

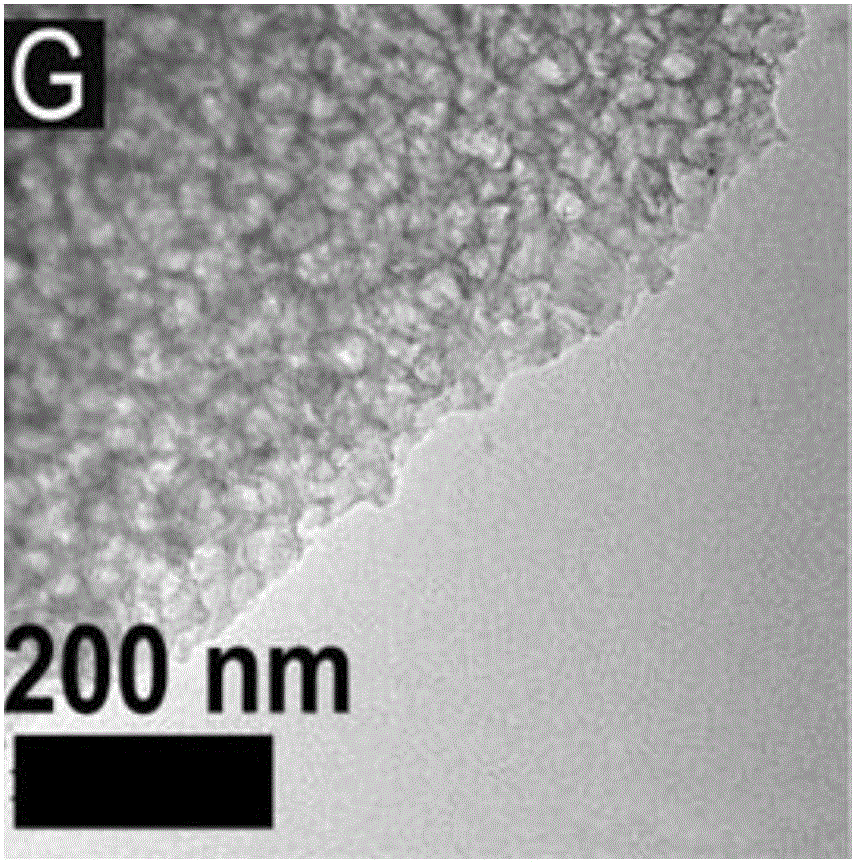

[0035] Embodiment 3, preparation of three-dimensional nitrogen-rich porous carbon material

[0036] 300mg of prepared ZIF-8 (40nm) and 600mg of PVP (molecular weight 1,300,000) were fully mixed in methanol, dried at room temperature for 24 hours to remove methanol, and the resulting mixture was placed in a tube furnace with a heating rate of 2°C / min under nitrogen Under protection, it was raised to 900°C, kept for 2 hours, cooled to room temperature with the furnace, taken out, placed in 30% hydrofluoric acid and stirred for 24 hours, filtered, washed with distilled water, and dried at 60°C to obtain the product. Scanning electron microscope picture as figure 2 shown.

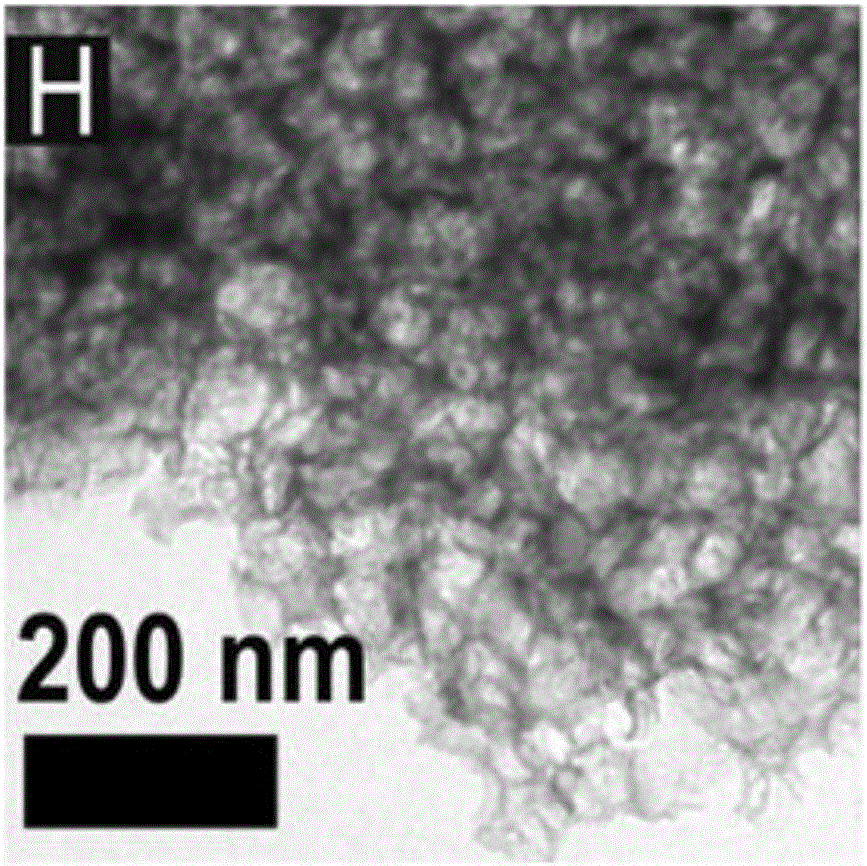

[0037] 300mg of prepared ZIF-8 (80nm) and 600mg of PVP (molecular weight 1,300,000) were fully mixed in methanol, dried at room temperature for 24 hours to remove methanol, and the resulting mixture was placed in a tube furnace with a heating rate of 2°C / min under nitrogen Under protection, it was raised to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com