Adjustable mold for manufacturing door and window lintel precast block, and using method thereof

A prefabricated block and adjustable technology, which is applied in the direction of molds, manufacturing tools, mold fixtures, etc., can solve the problems of poor appearance of door and window lintels and prefabricated blocks, limited turnover times of wooden formwork, and different lengths and heights. Strong performance and practicability, reduced construction cost, good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The technical solutions of the present invention are described in detail below through the examples, and the following examples are only exemplary, and can only be used to explain and illustrate the technical solutions of the present invention, but cannot be construed as limitations to the technical solutions of the present invention.

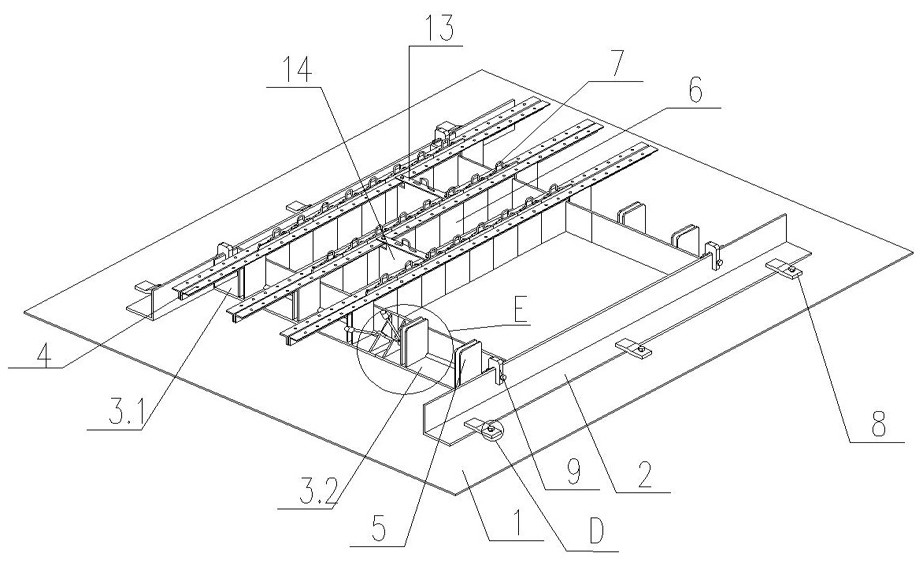

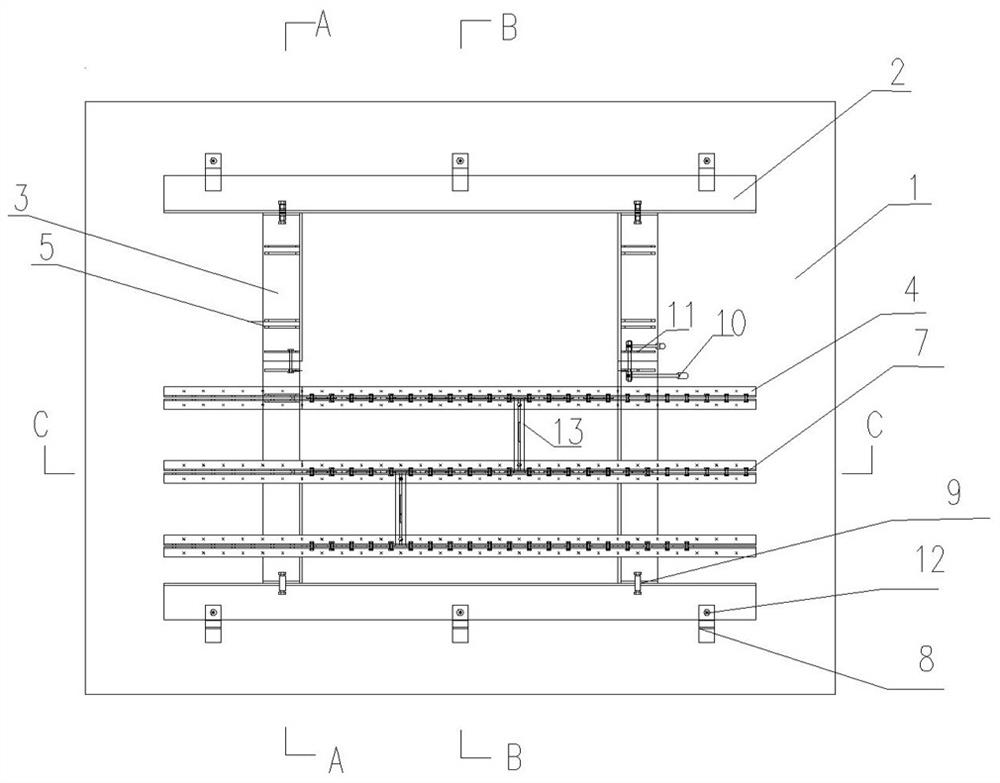

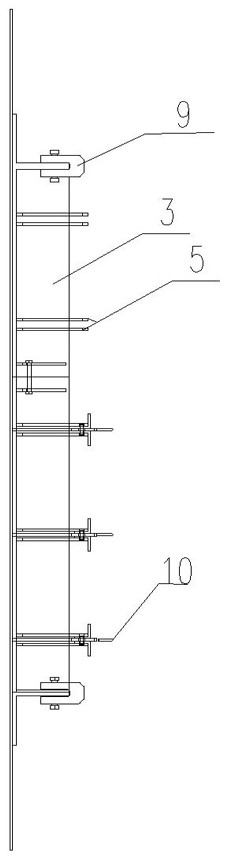

[0053] Such as Figure 1-8 As shown, the present invention provides an adjustable mold for making door and window lintel prefabricated blocks and a method of use thereof, including a bottom template 1, a lateral side mold 2, a longitudinal side mold 3, an inner mold clamp 4, a positioning block 5, Detachable inner mold 6, pressure plate 8, U-shaped side mold fixture 9, connecting mechanism, fastening bolt 12, positioning plate 13, movable inner mold 14; the upward side of the bottom template 1 is vertically provided with a plurality of positioning blocks 5. The detachable inner mold 6 and the movable inner mold 14; the horizontal side mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com