Decorative board film coating device

A decorative sheet and lamination technology, applied in lamination devices, lamination, layered products, etc., can solve the problems of difficulty in replacing the upper rollers, inconvenient adjustment of the spacing between the rollers, etc., to reduce the difficulty of replacement and facilitate disassembly , the effect of convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

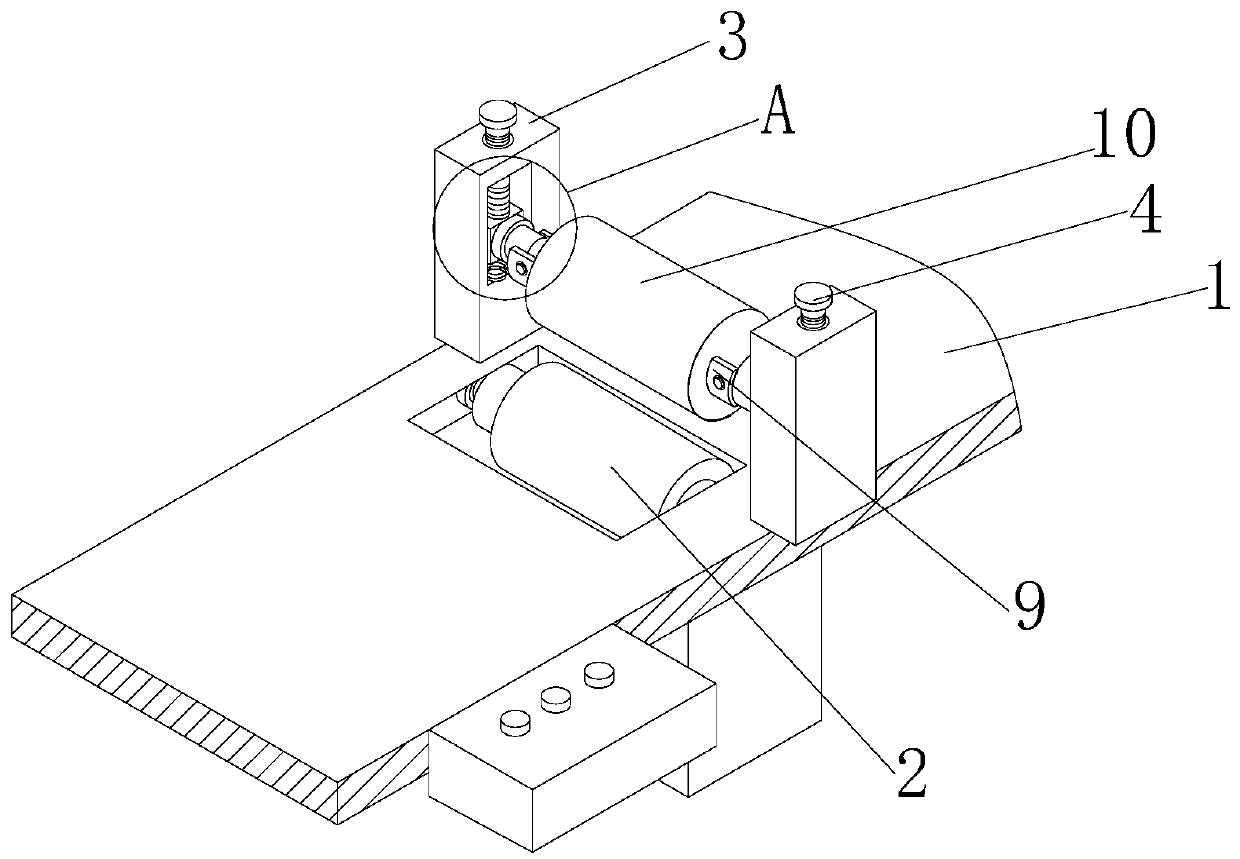

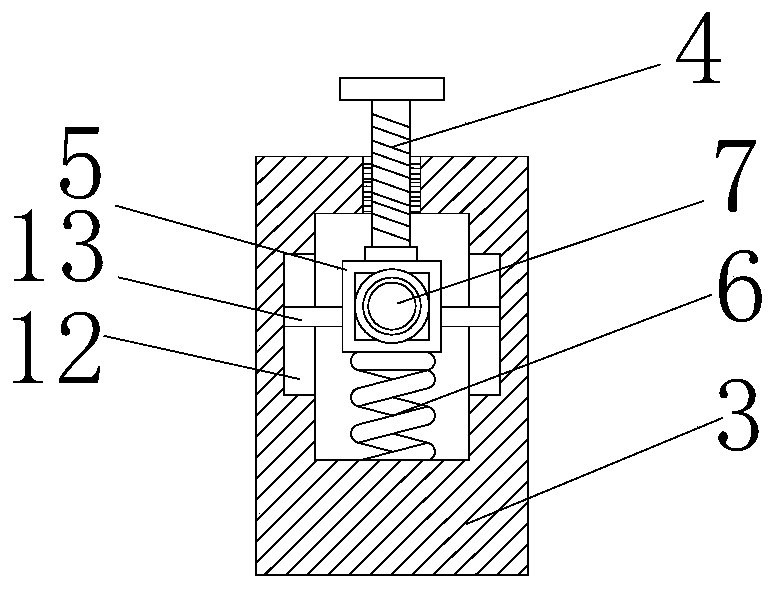

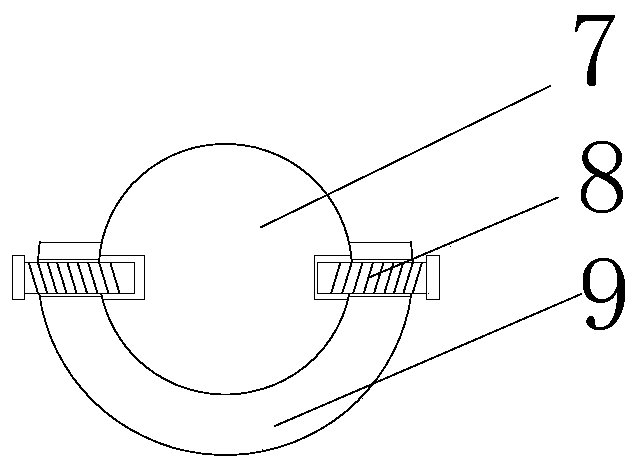

[0022] see Figure 1-4 , a decorative sheet coating equipment, comprising a body 1, the front and rear sides of the inner cavity of the body 1 are connected to the lower shaft roller 2 through bearing rotation, the front and rear sides of the top of the body 1 are welded with a box body 3, inside the box body 3 The top of the cavity is threaded with bolt 4, the bottom of bolt 4 is connected with support frame 5 through bearing rotation, the bottom of support frame 5 is welded with spring 6, the bottom end of spring 6 is welded with the inner wall of box body 3, and the inner wall of support frame 5 The shaft 7 is connected to the shaft through bearing rotation, and the two sides of the surface of the shaft 7 are fixedly connected with the concave seat 9 by the screw 8, and the upper shaft roller 10 is welded on the opposite side of the concave seat 9, and the box body 3 is oppositely viewed. One side is provided with a through groove 11, and the opposite side of the shaft rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com