A hydraulic inclined hole reamer

A hole reamer and oblique hole technology, which is applied in the direction of fluid pressure actuation device, fluid pressure actuation system safety, servo meter circuit, etc., can solve the problem of unfavorable carrying and use of personnel, large volume of oil circuit, hole reamer Large structure, etc., to achieve the effect of convenient one-handed operation, high work efficiency, and shortened oil return path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

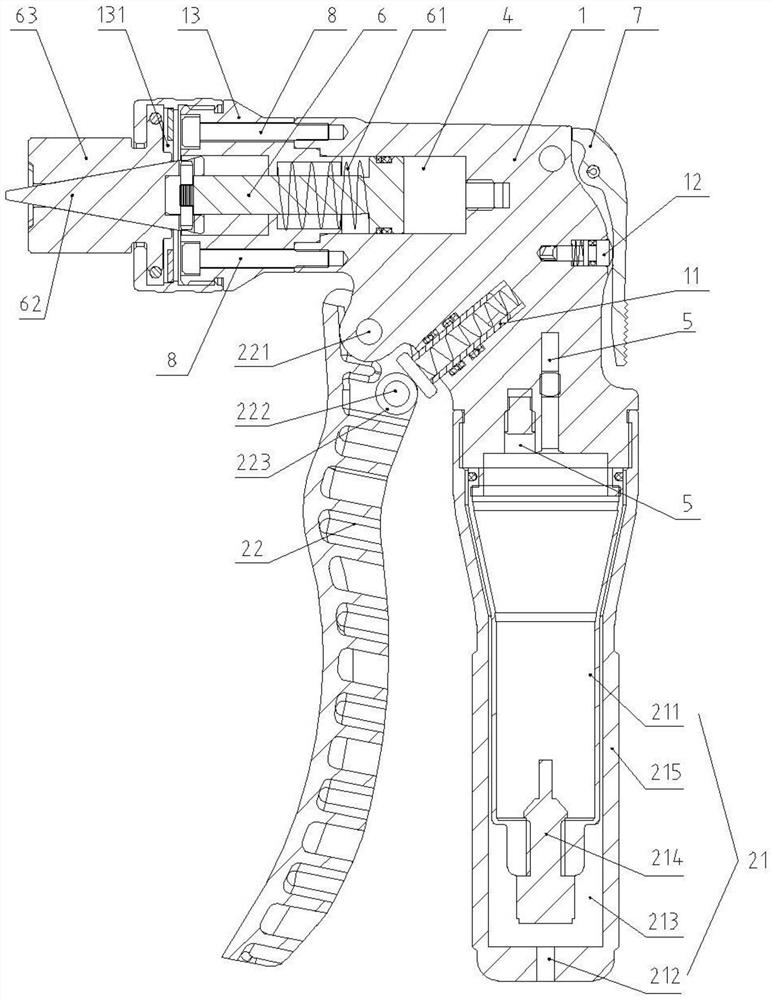

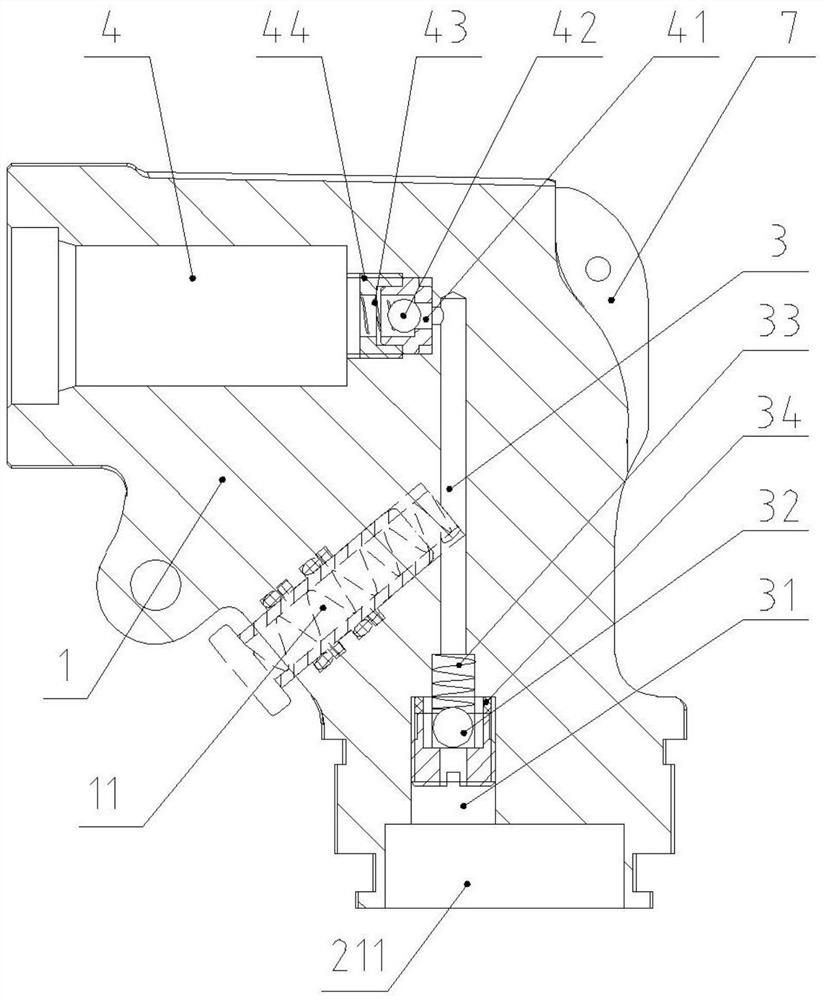

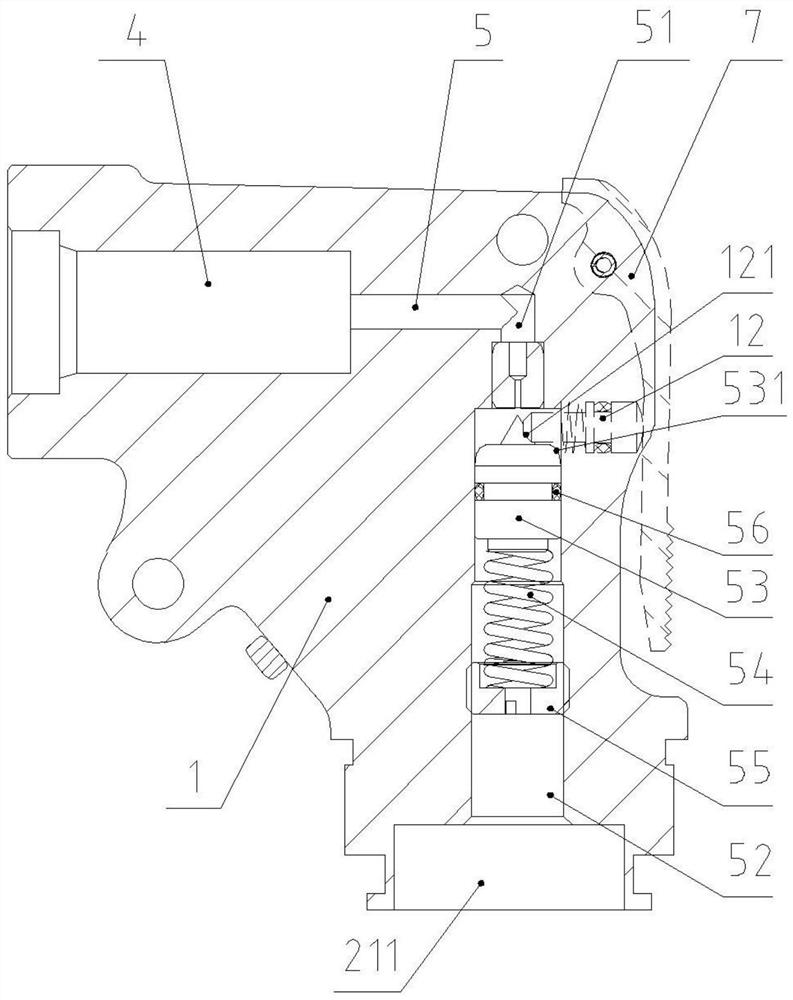

[0038] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see Figure 1-Figure 3 :

[0039] Such as figure 1 As shown, a hydraulic oblique hole reamer includes a pump body 1, a fixed handle 21 clamped on the pump body 1 and a drive mechanism hinged on the pump body 1, and an oil inlet channel is opened in the pump body 1 3. The working oil chamber 4 and the oil outlet channel 5, the fixed handle 21 is provided with an oil storage bag 211 inside, and the oil storage bag 211 communicates with the working oil chamber 4 through the oil inlet channel 3 and the oil outlet channel 5 respectively ; The oil inlet channel 3 is detachably provided with a one-way valve that allows the oil to enter the working oil chamber 4 in one direction; the pump body 1 is provided with a slot hole, and an oil pump core 11 is arranged obliquely in the slot hole , wherein, one side of the inner end of the oil pump core 11 is snappe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com