Nitrogen doped graphene quantum dot/mesoporous titanium dioxide photocatalyst and preparation method thereof

A technology of graphene quantum dots and mesoporous titanium dioxide, which is applied in the field of energy and the environment, can solve problems such as reducing photocatalytic performance, and achieve the effect of improving photocatalytic efficiency and photocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] This embodiment provides a method for preparing a nitrogen-doped graphene quantum dot / mesoporous titanium dioxide photocatalyst, the specific steps are as follows:

[0030] 1) Add 0.23g of citric acid and 0.23g of thiourea (or 0.18g of urea) into an appropriate amount of deionized water, ultrasonically disperse the mixed solution and transfer it to a hydrothermal reactor, and react at 160°C for 4 hours; wash the product The nitrogen-doped graphene quantum dots can be obtained by drying.

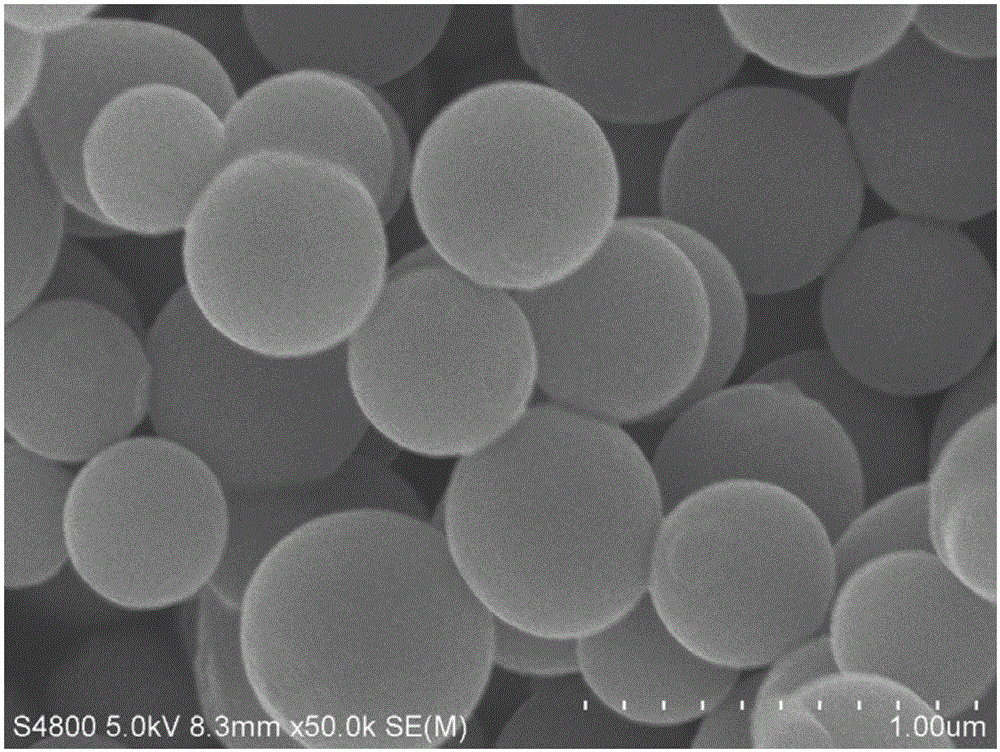

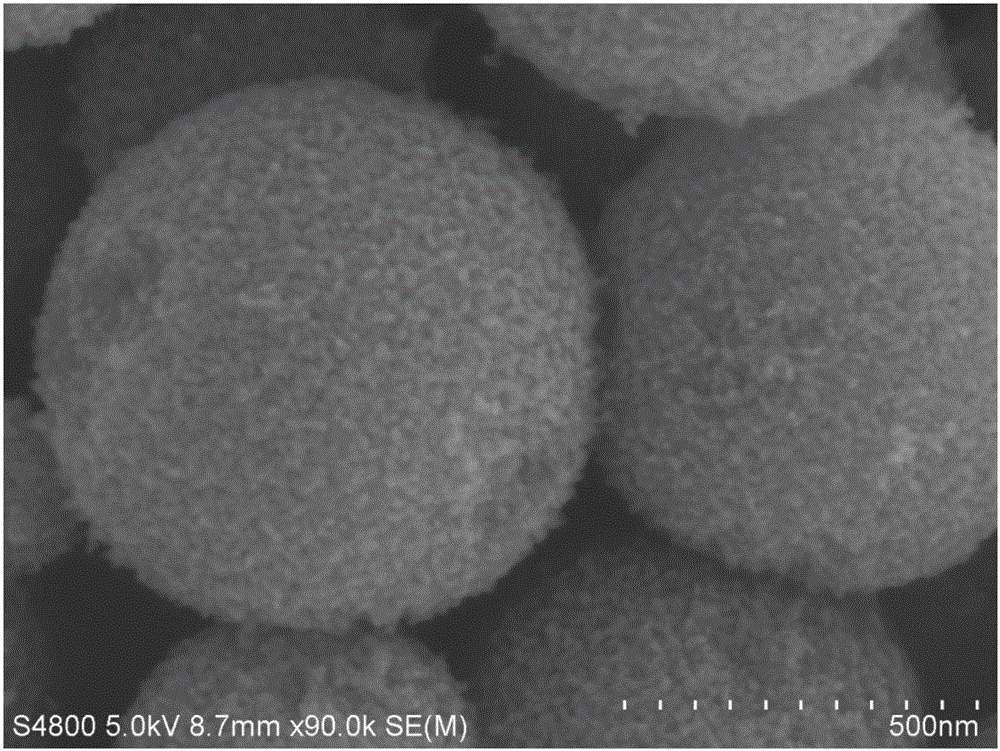

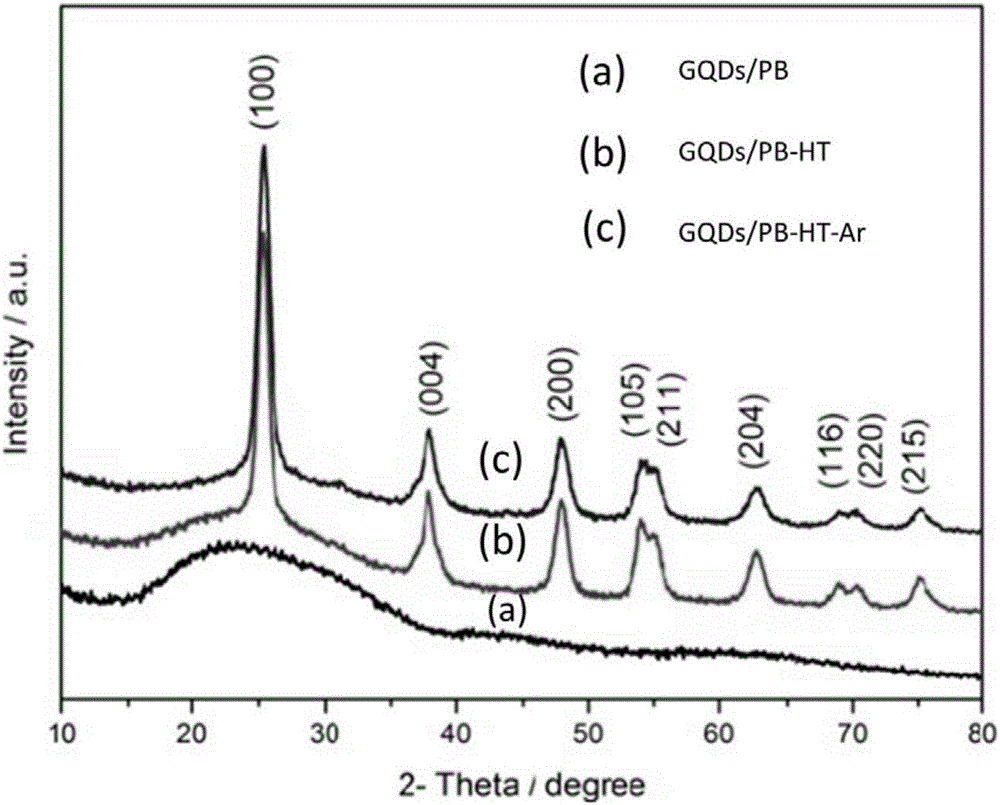

[0031] 2) 2.648g hexadecylamine was dissolved in 400ml absolute ethanol solution and stirred. Then take 48 mg of nitrogen-doped graphene quantum dots obtained in step 1) and dissolve them in 1.60 ml of deionized water, ultrasonically add them to the above solution, and after stirring evenly, add 1.60 ml of potassium chloride solution (0.1 mol / L) and 8.8 ml of isopropyl titanate (95% pure), and then left to stand for 18 hours. The reaction solution is filtered and washed repeatedly wi...

Embodiment 2

[0041] This example is similar to Example 1, except that the mass of nitrogen-doped graphene quantum dots in Example 1 is 96 mg. During the preparation of titanium dioxide, it can be seen that the color of the upper layer solution is blue, indicating that there are nitrogen-doped graphene quantum dots dispersed in the solution. Miscellaneous graphene quantum dots, while the upper solution in Example 1 is colorless. After the test, it was found that the microstructure morphology of the prepared nitrogen-doped graphene quantum dot / mesoporous titanium dioxide photocatalyst was the same as in Example 1, and its photocatalytic performance was as follows: Figure 5 shown.

Embodiment 3

[0043]The present embodiment is similar to Example 1, except that the quality of nitrogen-doped graphene quantum dots in Example 1 is 24 mg. After the test, it is found that the prepared nitrogen-doped graphene quantum dots / mesoporous titanium dioxide photocatalyst The microstructure morphology is the same as that of Example 1, and its photocatalytic performance is as follows: Figure 5 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com