Multi-component fuel gas mixing system for pre-combustion heating type constant volume bomb

A technology of mixing system and constant volume bomb, applied in the directions of gas and gas/vapor mixing, mixer, mixing method, etc., can solve the problems of easy interference, local accumulation, difficult sealing performance, etc., to avoid local accumulation and gas mixing. The effect of uniform and increased acquisition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

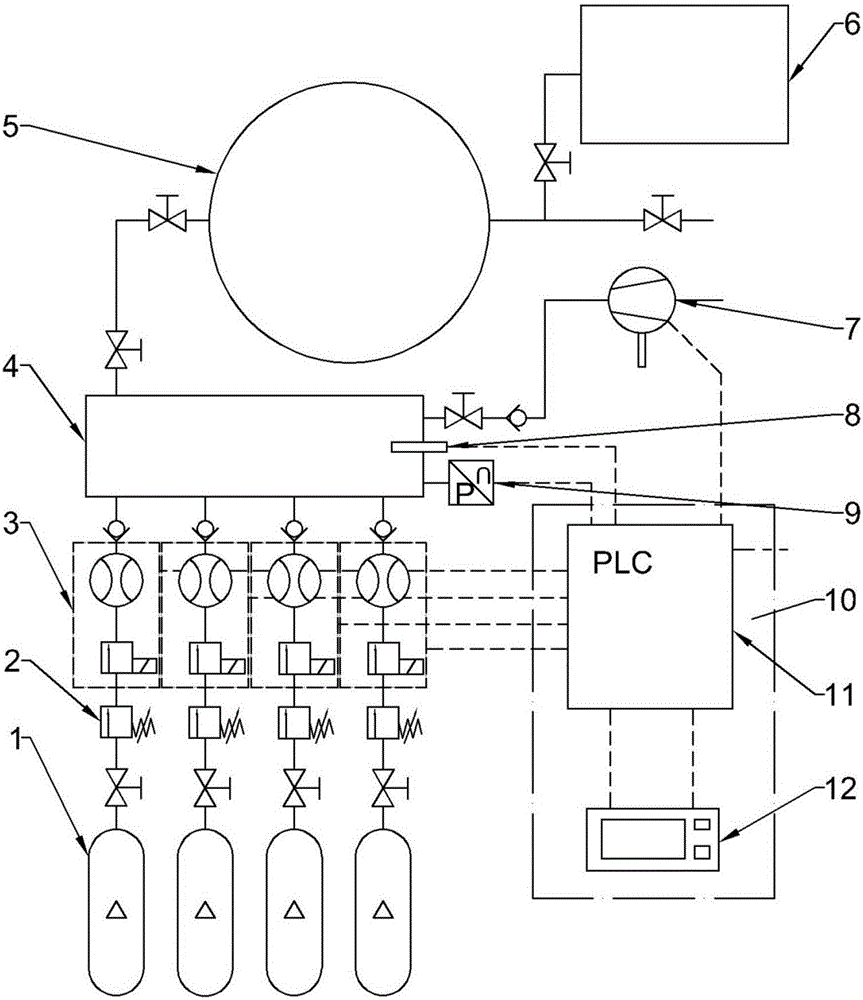

[0015] Such as figure 1 Shown: the multi-component gas mixing system of a kind of pre-combustion heating type constant volume bomb of the present invention, its purpose is to mix multiple gases, such as hydrogen (H 2 ), acetylene (C 2 h 2 ), oxygen (O 2 ), nitrogen (N 2 ) and other four kinds of gases are mixed into the fuel gas of the required ratio of the constant volume bomb, and the constant volume bomb is inflated, which includes a gas mixer 4, four gas cylinders 1 corresponding to the gas types as gas sources, and four gas cylinders 1 They are respectively connected to the gas mixer 4 through pipelines, and a flowmeter 3 with on-off function is arranged on each of the four pipelines, wherein the flowmeter can obtain the total flow rate during the ventilation process, and a pressure sensor is also installed on the gas mixer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com