A lithium ion battery and a preparation method thereof

A lithium-ion battery and lithium cobalt oxide technology, which is applied in the direction of secondary batteries, battery electrodes, battery components, etc., to achieve the effects of avoiding local heat accumulation, preventing positive and negative short circuits, and good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

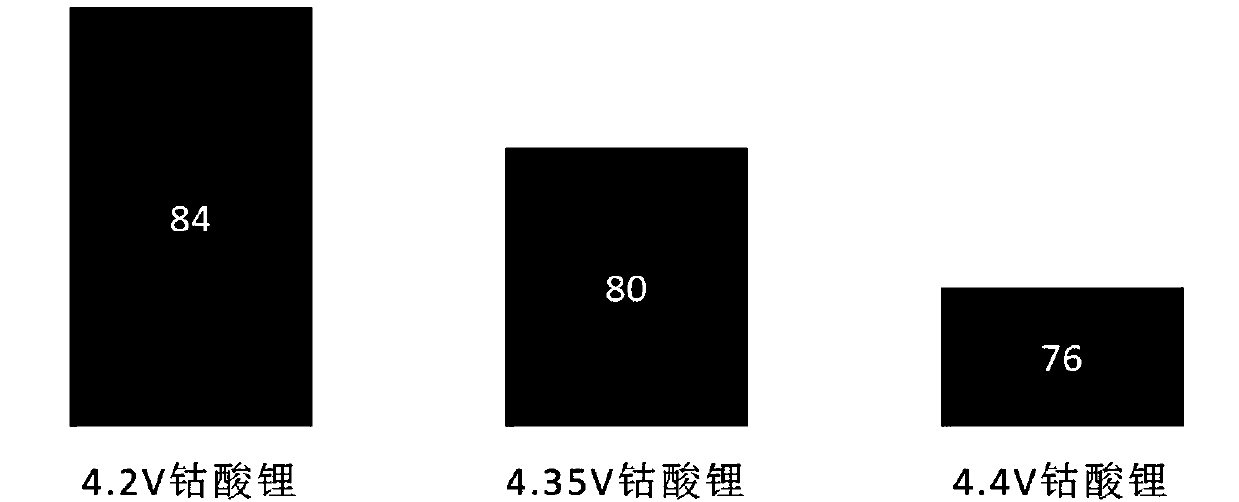

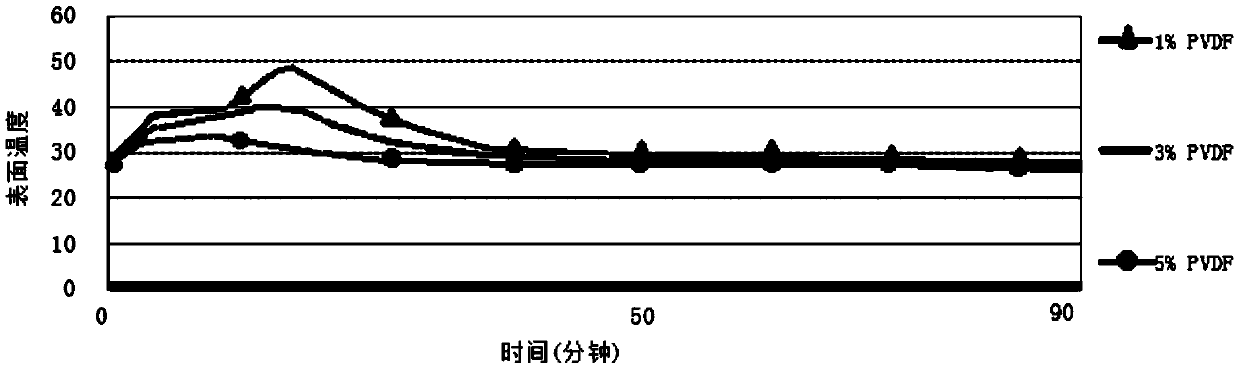

[0033] Weigh 96.8wt% positive electrode active material 4.4V high-voltage lithium cobaltate, 2wt% super conductive carbon black, 1.2wt% binder polyvinylidene fluoride, and use N-methylpyrrolidone as a solvent to make a slurry. Thick aluminum foil is used as a current collector, and the slurry is coated on both sides of the aluminum foil and dried; the pole piece is rolled to make a positive pole piece, and the density of both sides of the pole piece is 408mg / cm 2 . With 94.5wt% mesocarbon microsphere graphite (material appearance as image 3 Shown), 1wt% super conductive carbon black, 3.5wt% binder polyvinylidene fluoride, using N-methylpyrrolidone as a solvent to make a slurry, using 8um thick copper foil as a current collector, double the slurry The surface is coated on copper foil and dried; the pole piece is rolled to make a negative pole piece, and the density of both sides of the pole piece is 198mg / cm 2 . The PP / PE / PP three-layer base film is stacked to form a base f...

Embodiment 2

[0035] The difference between this example and Example 1 is that the positive electrode raw material components are as follows: 98wt% positive electrode active material 4.45V high voltage lithium cobaltate, 0.5wt% super conductive carbon black, 1.5wt% binder polyvinylidene fluoride , the positive electrode slurry is coated on one side of the positive electrode current collector; the negative electrode raw material components are as follows: 96wt% mesocarbon microsphere graphite, 0.5wt% super conductive carbon black, 3.5wt% binder polyvinylidene fluoride, negative electrode slurry The material is coated on the negative electrode current collector on one side; on the PP / PE / PP base film layer, the ceramic adhesive material is mixed on one side to make the battery separator.

Embodiment 3

[0037] The difference between this example and Example 1 is that the positive electrode raw material components are as follows: 90wt% positive electrode active material 4.35V high-voltage lithium cobaltate, 5wt% super conductive carbon black, 5wt% binder polyvinylidene fluoride, positive electrode The slurry is coated on one side of the positive electrode current collector; the raw material components of the negative electrode are as follows: 90wt% mesocarbon microsphere graphite, 5wt% super conductive carbon black, 5wt% binder polyvinylidene fluoride, and the negative electrode slurry is coated on both sides Covered on the negative electrode current collector; on the PP / PE / PP base film layer, the ceramic adhesive material is mixed and coated on one side to make the battery separator.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com