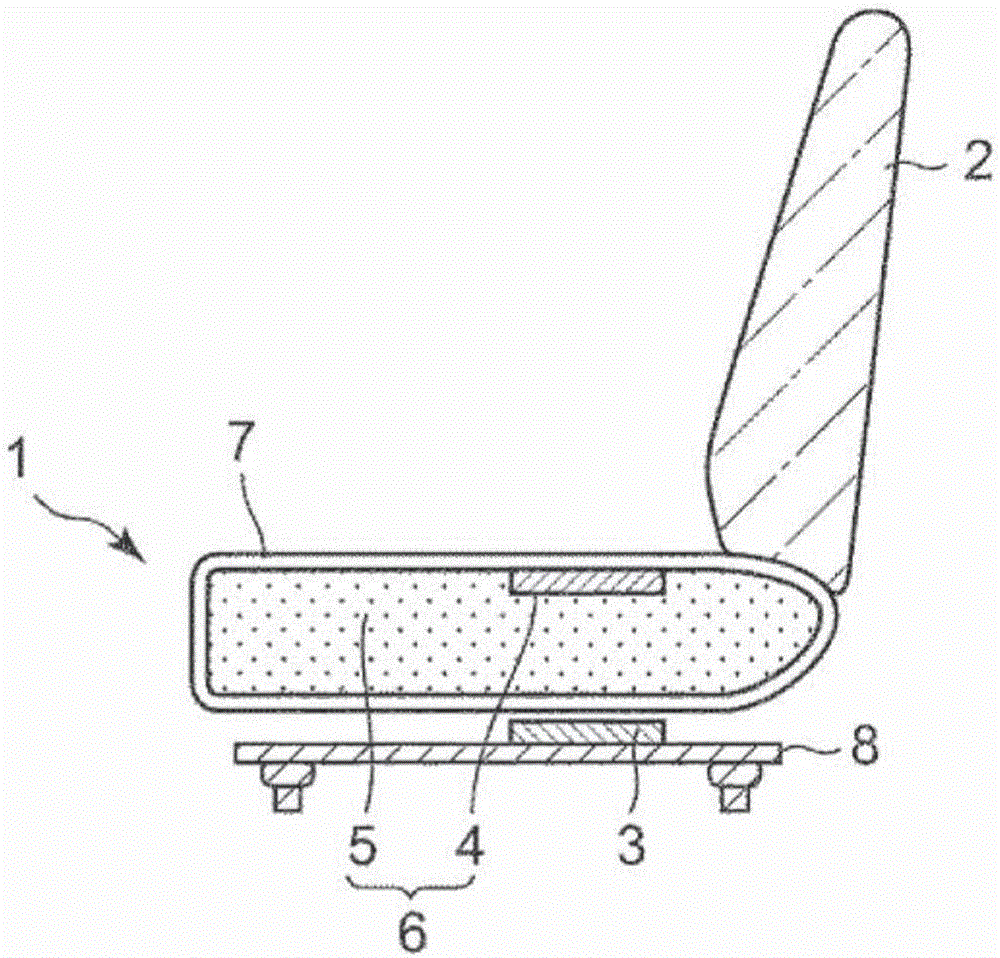

Cushion pad deformation detection system and production method therefor

A manufacturing method and technology of cushioning pads, applied in the field of deformation systems, can solve the problems of surface layer configuration of difficult-to-cushion materials, decreased configuration detection accuracy, foreign body sensation, etc., and achieve excellent self-adhesion, good riding experience, and less falling off. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

[0073] Manufacturing example 1 Synthesis of isocyanate-terminated prepolymer A

[0074] 85.2 parts by weight of polyol A (polyoxypropylene glycol to which propylene oxide was added with glycerin as an initiator, OH value 56, number of functional groups 3) was added to the reaction vessel, and vacuum dehydration was performed for 1 hour while stirring. Thereafter, the inside of the reaction container was replaced with nitrogen. Next, 14.8 parts by weight of toluene diisocyanate (manufactured by Mitsui Chemicals Co., Ltd., 2,4 type = 100%, NCO% = 48.3%) was added to the reaction vessel, and reacted for 3 hours while keeping the temperature in the reaction vessel at 80°C. Isocyanate-terminated prepolymer A (NCO% = 3.58%) was synthesized.

manufacture example 2

[0075] Manufacturing example 2 Synthesis of isocyanate-terminated prepolymer B

[0076] 81.2 parts by weight of polyol C (polyoxypropylene glycol to which propylene oxide was added with pentaerythritol as an initiator, OH value 75, number of functional groups 3) was added to the reaction vessel, and dehydration under reduced pressure was carried out for 1 hour while stirring. Thereafter, the inside of the reaction container was replaced with nitrogen. Next, 18.8 parts by weight of toluene diisocyanate (manufactured by Mitsui Chemicals Co., Ltd., 2,4 type = 100%, NCO% = 48.3%) was added to the reaction vessel, and reacted for 3 hours while keeping the temperature in the reaction vessel at 80°C. Isocyanate-terminated prepolymer B (NCO% = 4.55%) was synthesized.

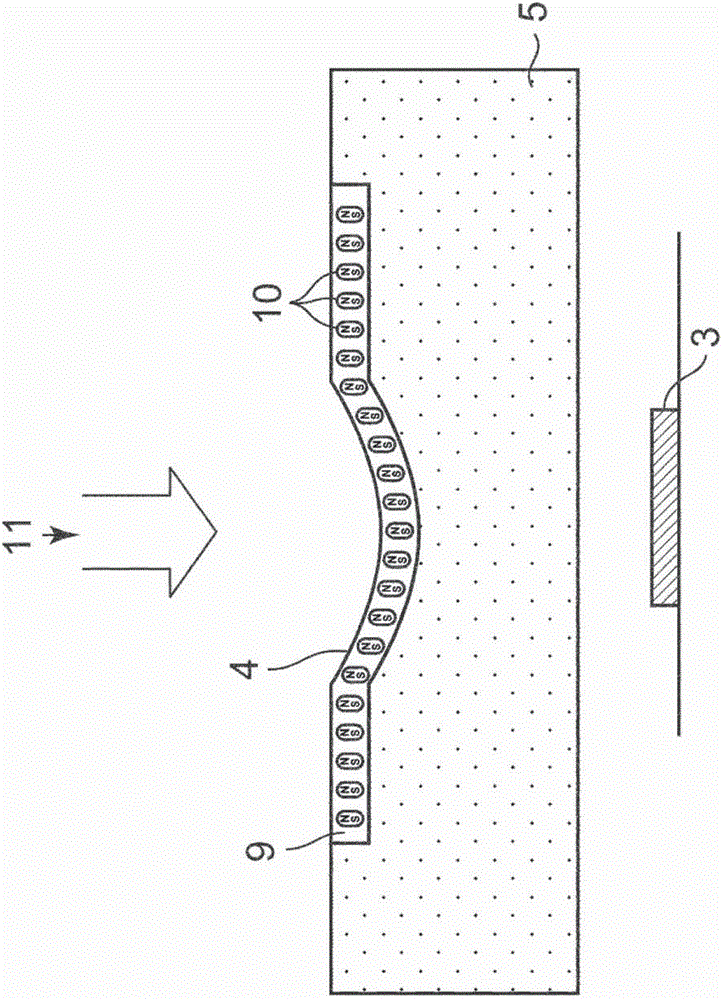

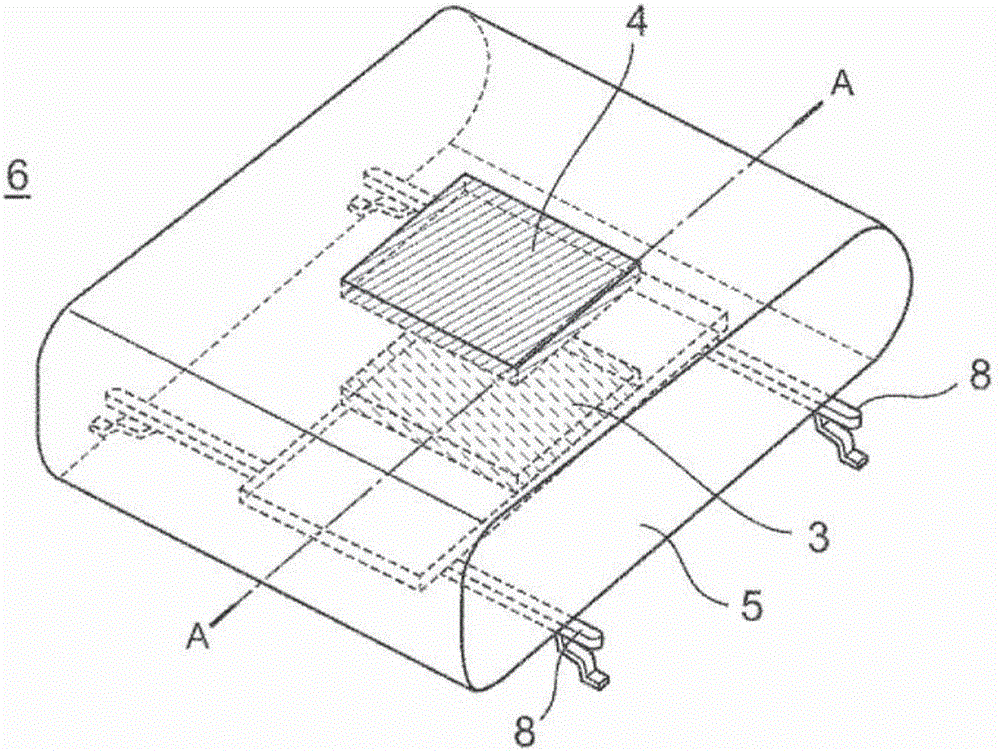

Embodiment 1

[0078] Next, a neodymium-based filler (manufactured by Aichi Steel Works, MF-15P, average particle diameter 133 μm) to 730.3 parts by weight to prepare a filler dispersion. The filler dispersion liquid was degassed under reduced pressure, and 100.0 parts by weight of the above-mentioned prepolymer A which had also been degassed under reduced pressure was added, and mixed and defoamed using a planetary mixer (manufactured by Shinki Co., Ltd.). The reaction liquid was dropped from a release-treated PET film having a spacer of 1.0 mm, and adjusted to a thickness of 1.0 mm using a nip roller. Thereafter, curing was performed at 80° C. for 1 hour to obtain a filler-dispersed polyurethane elastomer. A magnetic elastic body was obtained by magnetizing the obtained elastic body at 1.3 T in a magnetization device (manufactured by Denki Magnetic Industry Co., Ltd.).

[0079] The portion other than the seating surface of the obtained magnetic elastic body was abraded with #400 sandpape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com