A process and apparatus for purification of water

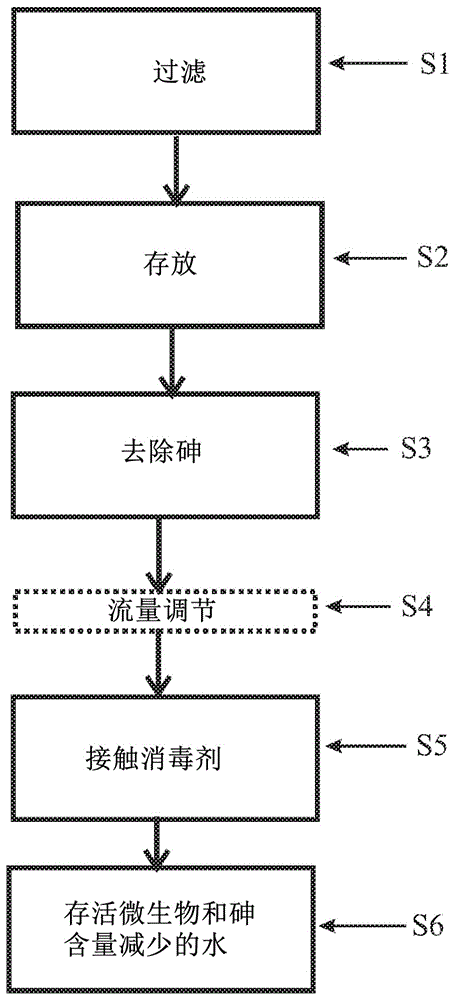

A process and equipment technology, applied in the field of water purification process, can solve the problems of inability to reduce arsenic and microbial pollutants at the same time, expensive process, continuous water source, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0088] Embodiment 1: According to the water purification process of the present invention, and analysis of arsenic removal effect

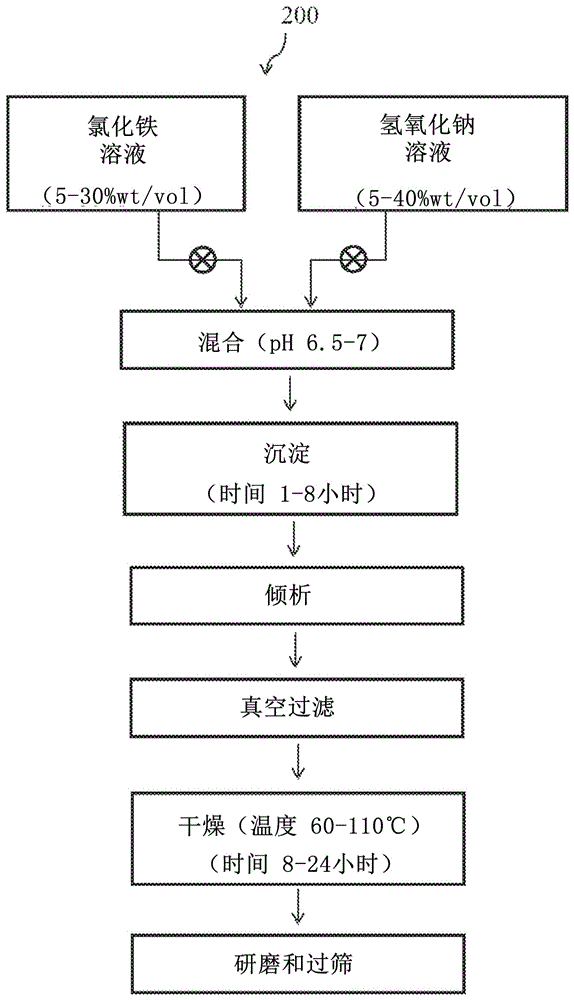

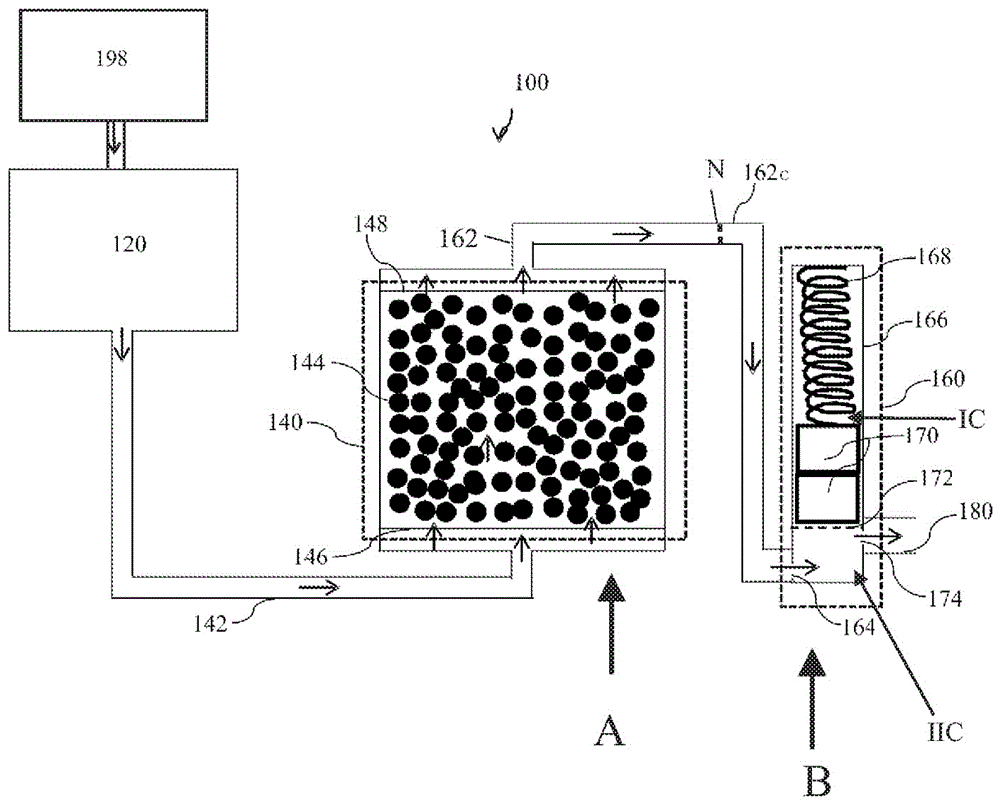

[0089] A bed of arsenic removal media was prepared in an 880 mm size cartridge using 378 grams of arsenic removal media. Add 20% wt / vol ferric chloride solution and 14% wt / vol sodium hydroxide solution into water simultaneously, keep stirring with a stirrer, and maintain the pH of the solution at 6.8. Wait for the suspension to settle for 8 hours and remove the supernatant by decantation followed by vacuum filtration. The filter residue was dried in an oven at 65°C for 24 hours, and the dried filter residue was granulated to obtain particles that could pass through a sieve with a size of 850 microns and remain on a sieve with a size of 425 microns. To test for arsenic removal, the cartridges were connected to a point-of-use (POU) system source tank for holding arsenic-contaminated water and a collection tank for collecting cartridge-purified water....

Embodiment 2

[0090] Embodiment 2: according to water purification process of the present invention, and microbial activity elimination effect analysis

[0091] In order to test the bacteria and virus activity elimination effect of the water purification process, a cartridge similar to the cartridge introduced in Example 1 was prepared, and the chlorine release system prepared by two trichloroisocyanuric acid tablets was placed in a shell with inlet and outlet holes. Between the diffuser membrane and the spring in the body. Chlorine-releasing tablets were prepared using 1.5 g of trichloroisocyanuric acid and a diffusion film was prepared using felt cloth. Water from the bed of arsenic removal media enters the disinfectant delivery system, where it contacts the diffusion membrane and forms an outlet. A cartridge consisting of an arsenic removal media bed and a chlorine release system was connected to the POU system source tank and tested with groundwater for bacteria and viruses. To determ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com