Adsorbent applicable to flue gas dearsenization and dearsenization method thereof

An adsorbent and flue gas technology, applied in the field of flue gas pollution removal, can solve the problems of limited arsenic removal effect in flue gas, and achieve the effects of reducing arsenic content, improving adsorption effect, and long reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

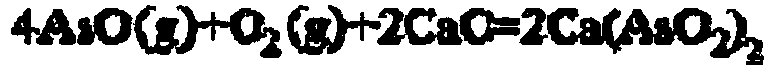

Method used

Image

Examples

Embodiment 1

[0026] An adsorbent for flue gas dearsenization of the present invention includes calcium oxide, metallurgical slag, zeolite and fly ash. The addition of fly ash is M4=γ(M1+αM2-δM3)-β / (1-α)M2, wherein: M1 is the quality of calcium oxide, M2 is the quality of metallurgical slag, and M3 is the quality of zeolite; Take 0.15~0.25, δ takes 1.5-2, where it is worth noting that: α is the mass percentage of CaO and MgO in metallurgical slag; β is the content of Fe in metallurgical slag 2 o 3 and MnO mass percent content. The mass ratio of calcium oxide to zeolite is 4-8, and 5 is used in this embodiment.

[0027] Calcium oxide 60kg of the present embodiment, metallurgical slag 20kg, zeolite 12kg; Calculate the quality of fly ash to be: M4=γ(60+α20-δ12)-β / (1-α)20=8.14kg wherein γ gets 0.2 , δ is taken as 1.5, the fly ash has a larger specific surface area, and the fly ash and zeolite have a better adsorption effect on arsenic, so that the residence time of arsenic and its oxides on ...

Embodiment 2

[0052] The basic content of this embodiment is the same as that of the embodiment, except that it also includes additives, and the additives include blast furnace ash, chrome slag and mullite; each component is composed according to the following parts by mass: blast furnace ash: 60%, chromium Slag: 20%, mullite: 20%. The additive is added in an external manner, and the amount of the additive is 1-2% of the adsorbent, which is 1% in this embodiment, that is, the amount of the additive is 1% of the sum of the mass of calcium oxide, metallurgical slag, zeolite and fly ash. -2%. Under high temperature conditions, the metal elements in the additives promote the electron shift in fly ash and converter slag under high temperature conditions, thereby promoting the arsenic in the flue gas to enter the vacancies and bridges of O in calcium oxide, improving In addition, the metal in the additive promotes the arsenic in the fly ash to enter the vitreous aluminosilicate mineral lattice, ...

Embodiment 3

[0066]The basic content of this embodiment is the same as that of Embodiment 1, and an accelerator is also included, and the accelerator is an organic substance with an aspect ratio greater than 1000. The accelerator in this embodiment is plant fiber or animal hair fiber or plastic fiber, and the accelerator is added in an external manner. The addition amount of calcium oxide, metallurgical slag, zeolite and fly ash quality sum 0.05-0.2%; What present embodiment adopts is the mixture of animal hair fiber and cotton fiber, and the ratio of the quality of hair fiber and cotton fiber is 2 : 1; by adding hair fiber and cotton fiber in the adsorbent, larger mesopores can be distributed in the adsorption after treatment, which greatly improves the adsorption specific surface area of the adsorbent, and can improve the adsorption effect of the adsorbent; in addition, The pores are connected to each other, thereby promoting the transformation from physical adsorption to chemical adso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com